Des . 24, 2024 04:50 Back to list

high quality plgt-1000n full-auto hdaf rotary paper pleating production line

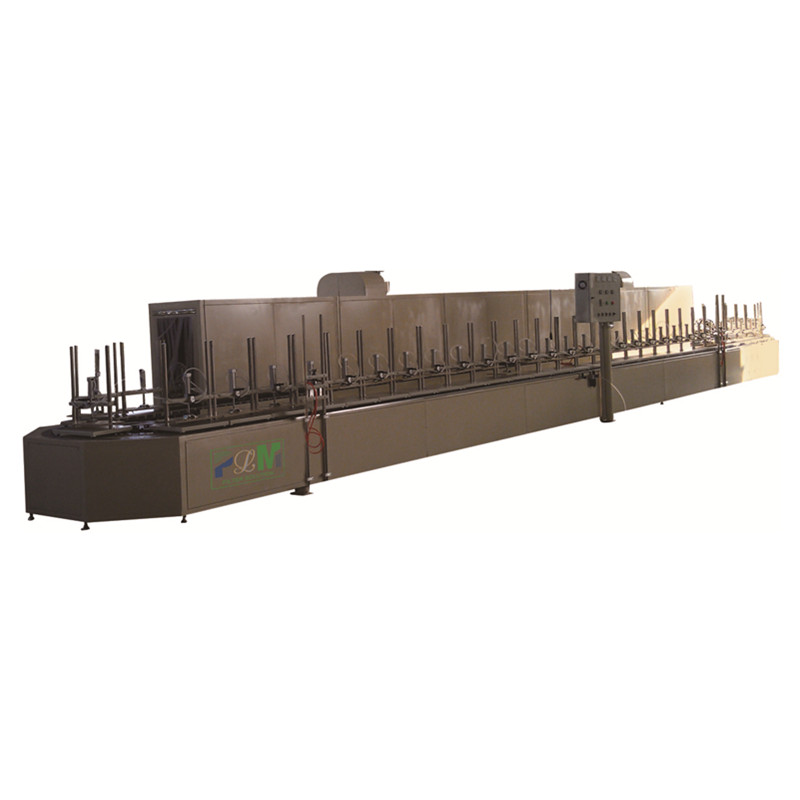

High-Quality PLGT-1000N Full-Auto HDAF Rotary Paper Pleating Production Line

In the realm of industrial manufacturing, the demand for efficiency and quality continues to grow, particularly in the paper product industry. Among the innovations that have emerged to meet these demands is the PLGT-1000N Full-Auto HDAF Rotary Paper Pleating Production Line. This advanced production line stands out due to its state-of-the-art technology which enhances productivity while maintaining high standards of quality.

Overview of the PLGT-1000N Production Line

The PLGT-1000N is designed specifically for the production of pleated paper products. Whether it’s for use in filters, packaging, or decorative arts, this machine is capable of fulfilling a variety of manufacturing needs. The full-automatic nature of the machine reduces the likelihood of human error, thus ensuring consistent product quality and minimizing waste.

Key Features

1. High Automation The fully automatic operation means that once the setup is complete, the machine can run autonomously. This feature not only boosts productivity but also allows manufacturers to allocate human resources to other tasks, thereby optimizing workforce efficiency.

2. Precision and Quality Control The PLGT-1000N is equipped with advanced sensors and control systems that ensure each pleat is formed accurately. This precision is crucial in applications where the exact dimensions and folds of the paper significantly affect the product's performance.

3. Versatility in Production This production line can handle various types of paper, including recyclable, biodegradable, and specialized papers. The ability to adjust settings on the fly allows manufacturers to switch between different products without requiring extensive reconfiguration.

4. User-Friendly Interface The machine features an intuitive control panel that makes operating the system straightforward. Even operators with limited experience can quickly learn to operate the line, allowing for smoother transitions during shifts or new employee training.

high quality plgt-1000n full-auto hdaf rotary paper pleating production line

5. Energy Efficiency In today’s eco-conscious environment, energy efficiency is paramount. The PLGT-1000N is designed with energy-saving technology, helping manufacturers reduce their carbon footprint while lowering operational costs.

Applications of the PLGT-1000N

The versatility of the PLGT-1000N Production Line allows it to cater to numerous sectors. Some of the primary applications include

- Air and Water Filtration Pleated paper is extensively used in filter manufacturing due to its increased surface area and efficiency in trapping particulates. - Food Packaging In the food industry, pleated paper is used for packaging to ensure products remain fresh and free from contaminants. - Arts and Crafts The production line can also be adapted for the artistic sector, creating decorative paper elements for various craft projects.

Advantages of the PLGT-1000N

Investing in the PLGT-1000N production line provides numerous advantages for manufacturers

- Increased Output The automation and rapid processing capabilities lead to significantly higher output compared to traditional methods. - Cost Reduction While the initial investment might be substantial, the reduction in labor costs, waste, and downtime results in lower long-term operational costs. - Enhanced Product Quality With precise technology, manufacturers can ensure their end-products meet the high standards required in competitive markets.

Conclusion

In conclusion, the PLGT-1000N Full-Auto HDAF Rotary Paper Pleating Production Line is an essential asset for modern paper manufacturing facilities looking to improve efficiency, reduce costs, and enhance product quality. Its advanced features and capabilities not only streamline production processes but also contribute to meeting the increasing demands of various industries. As manufacturers continue to seek ways to innovate and improve, the PLGT-1000N stands as a testament to the possibilities that modern technology brings to the traditional art of paper manufacturing. Embracing such advancements will be key to thriving in the competitive landscape of the paper product market.

-

OEM PLKJ-20 Filter Paper Pore Size Tester Precision Measurement

NewsMay.19,2025

-

Affordable PLNP-1 Bursting Strength Tester Low-Cost & Reliable

NewsMay.19,2025

-

Premium Toyota Air Filter Machines OEM Suppliers & Manufacturers

NewsMay.19,2025

-

OEM Truck Air Filters Machine Production Line - Custom Solutions

NewsMay.18,2025

-

Toyota Air Filter Producing Machine High-Efficiency Manufacturing Solutions

NewsMay.18,2025

-

Affordable Truck Air Filters High Quality & Low Cost

NewsMay.18,2025