ታኅሣ . 11, 2024 16:01 Back to list

High Efficiency Automatic Production Line for Assembling Sealing Rings

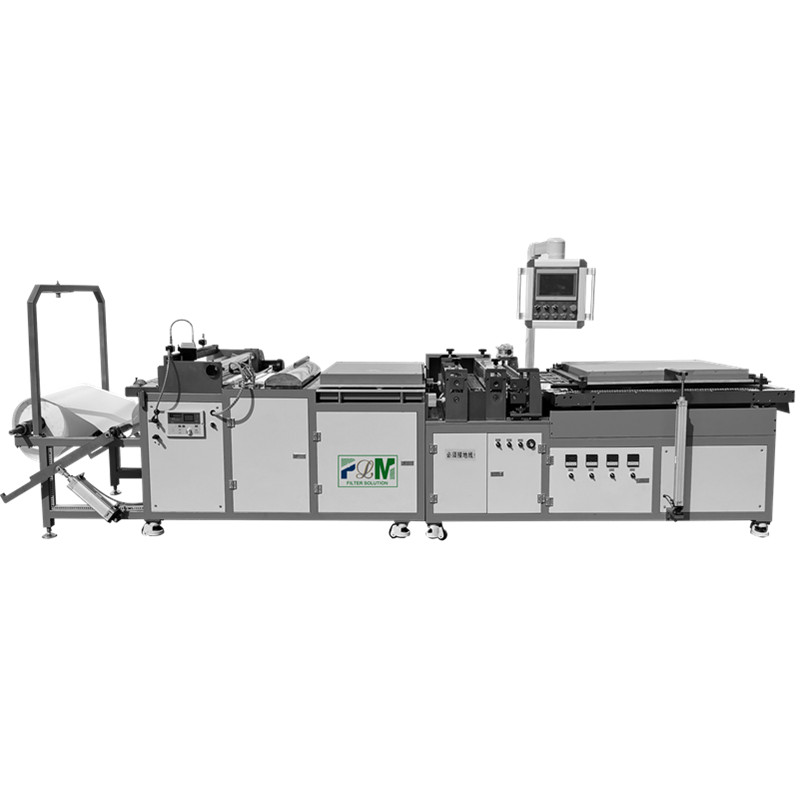

High-Quality PLMF-1 Automatic Production Line for Assembly of Sealing Rings

In the world of manufacturing, efficiency and precision are paramount, especially when it comes to producing components like sealing rings, which are critical in various applications ranging from automotive to aerospace industries. The emergence of the PLMF-1 automatic production line represents a significant advancement in technology, ensuring a high-quality output while optimizing production processes.

Understanding Sealing Rings

Sealing rings are essential components that prevent the leakage of fluids and gases in machinery and equipment. They come in various materials, sizes, and shapes, tailored to meet the specific needs of different applications. The quality of sealing rings directly influences the performance and longevity of the products they are used in, which is why advanced manufacturing technologies are essential for their production.

What is the PLMF-1 Production Line?

The PLMF-1 automatic production line is an innovative solution designed for the efficient assembly of sealing rings. Integrating cutting-edge technology, this production line automates the processes involved in manufacturing, which significantly enhances speed and precision. The line is engineered to handle various materials used in sealing rings, ensuring versatility in production capabilities.

Key Features of the PLMF-1 Production Line

1. Automation and Robotics One of the standout features of the PLMF-1 production line is its high level of automation. Through the use of advanced robotics, the line minimizes human intervention, which reduces the risk of errors and increases overall production speed. Robotic arms are programmed to perform tasks such as loading materials, assembling components, and quality checking, allowing for a seamless production flow.

2. Precision Engineering The PLMF-1 is designed with state-of-the-art precision engineering that enables it to achieve tight tolerances, which are crucial for the proper functioning of sealing rings. This precision ensures that each ring meets the exact specifications required for its application, thereby enhancing reliability and performance.

high quality plmf-1 automatic production line for assembly sealing ring

3. Real-Time Monitoring The integration of IoT (Internet of Things) technology allows for real-time monitoring of the production process. Operators can track performance metrics, detect anomalies, and maintain quality standards throughout the manufacturing cycle. This capability is vital for continuous improvement and minimizing downtime.

4. Customization Capabilities The PLMF-1 production line is capable of manufacturing sealing rings in various sizes and materials. This flexibility enables manufacturers to respond rapidly to market demands and customize products for specific applications, thereby increasing competitiveness.

5. Energy Efficiency In today’s industrial landscape, energy efficiency is a critical consideration. The PLMF-1 is designed to consume less power compared to traditional production methods. It employs energy-efficient motors and minimizes waste throughout the production process, contributing to a more sustainable manufacturing approach.

Benefits of Implementing the PLMF-1 Production Line

The adoption of the PLMF-1 automatic production line offers numerous benefits to manufacturers

- Increased Production Rate With the ability to operate continuously and efficiently, manufacturers can significantly increase their output without compromising quality. - Cost Reduction Automation reduces labor costs and minimizes waste, thereby lowering overall production costs. - Enhanced Product Quality Consistency in production leads to higher-quality sealing rings, which can enhance customer satisfaction and loyalty. - Scalability The system's flexibility allows for easy scaling of production volume to meet changing market demands without significant investment in new equipment.

Conclusion

The PLMF-1 automatic production line for the assembly of sealing rings marks a significant leap forward in manufacturing technology. Its combination of automation, precision engineering, and real-time monitoring not only enhances production efficiency but also ensures the high-quality output required in today’s competitive market. As industries continue to evolve, the PLMF-1 stands as a testament to innovation, paving the way for the future of manufacturing. By embracing such advanced solutions, companies can better meet the demands of their customers and secure their position in the market.

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025