ታኅሣ . 20, 2024 07:49 Back to list

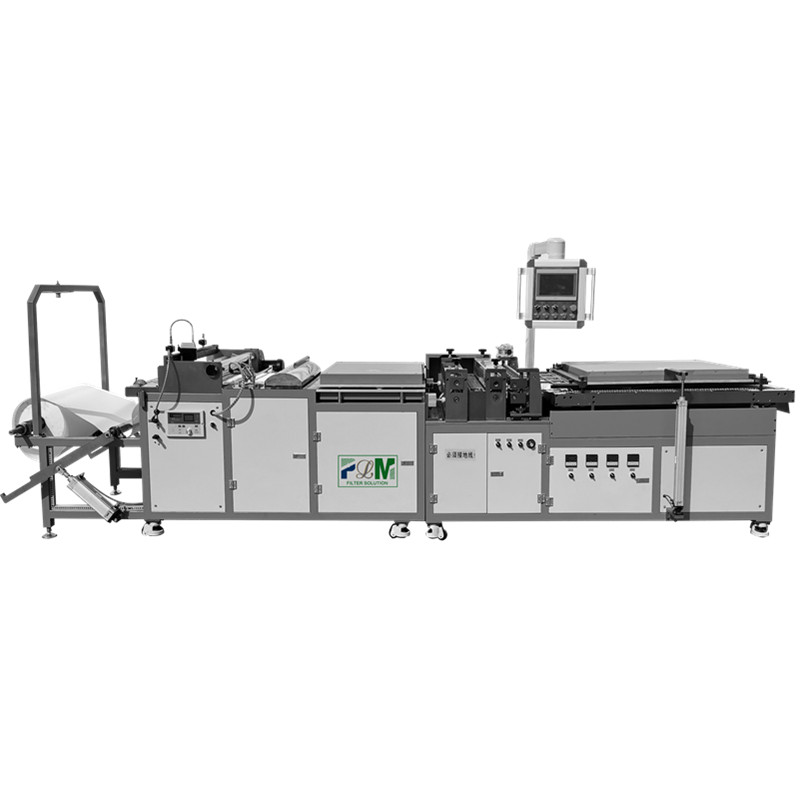

OEM PLFK-130 II Automatic Spin-On Filter Seaming Equipment for Efficient Production

The Evolution and Importance of the OEM PLFK-130-II Full-Auto Spin-On Filter Seaming Machine

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. This is especially true in the automotive industry, where the demand for high-quality components such as oil filters has surged. One of the pioneering solutions to meet this demand is the OEM PLFK-130-II Full-Auto Spin-On Filter Seaming Machine. This machine represents a significant advancement in the seamless production of filter elements, ensuring consistency, quality, and speed in manufacturing processes.

Understanding Spin-On Filters

Before delving into the specifics of the PLFK-130-II, it’s essential to understand what spin-on filters are and their role in automotive applications. Spin-on filters are essential components in oil filtration systems, designed to remove contaminants from engine oil, thereby protecting vital engine parts and improving performance. Their importance cannot be overstated, as clean oil significantly enhances engine lifespan and efficiency.

The Role of Seaming Machines

Seaming machines play a critical role in the manufacturing of spin-on filters. The seaming process involves securely attaching the filter's end caps to the body, creating a sealed unit that can withstand high pressure and intense operational conditions. This is where the OEM PLFK-130-II shines. It utilizes advanced technology to automate the seaming process, thereby reducing manual labor, minimizing human error, and increasing production speed.

Features of the PLFK-130-II

The OEM PLFK-130-II is a marvel of engineering, boasting a range of features designed to enhance operational efficiency and product quality. One of its standout features is its full automation capability. This automation allows for continuous operation, significantly increasing the output compared to manual processes. Operators can set the machine to run with minimal intervention, freeing up valuable resources and reducing operational costs.

oem plfk-130-ii full-auto spin-on filter seaming machine

Moreover, the PLFK-130-II is equipped with advanced sensors and control systems that ensure precise alignment and consistent seam quality. The machine automatically adjusts to different filter sizes and types, making it versatile for various production requirements. This adaptability is crucial, given the diverse needs of the automotive industry.

Additionally, the machine’s construction emphasizes durability and reliability. Built with high-quality materials, the PLFK-130-II can withstand the rigors of continuous operation while maintaining performance. The design also focuses on ease of maintenance, allowing operators to conduct regular checks and servicing with minimal downtime.

Benefits of Using the OEM PLFK-130-II

Investing in a PLFK-130-II Full-Auto Spin-On Filter Seaming Machine brings several benefits to manufacturers. First and foremost is the aspect of quality. The precision engineering of the machine guarantees that every seam meets strict industry standards. This quality assurance results in fewer defects, minimizing waste and rework costs.

Furthermore, the speed of production is significantly enhanced with the PLFK-130-II. Manufacturers can increase their output without compromising on quality, enabling them to meet larger orders and respond to market demands swiftly. This advantage is particularly vital in an industry characterized by fluctuating demand and tight deadlines.

Another major benefit is the reduction of labor costs. With automation taking over manual tasks, companies can optimize their workforce, allocating human resources to more strategic roles within the organization. This not only boosts productivity but also helps in cultivating a more skilled workforce focused on quality control and innovation.

Conclusion

The OEM PLFK-130-II Full-Auto Spin-On Filter Seaming Machine is a groundbreaking tool that has transformed the automotive manufacturing sector. By automating the seaming process, it offers manufacturers a competitive edge through improved efficiency, reduced costs, and enhanced product quality. As the industry continues to evolve, machines like the PLFK-130-II will play a pivotal role in shaping the future of automotive components, ensuring that manufacturers can keep pace with the demands of innovation and quality. Investing in such advanced machinery not only positions companies for success today but also sets the foundation for sustained growth in the years to come.

-

37010 Auto Engine Oil Filter Premium Quality & Extended Engine Life

NewsMay.20,2025

-

Custom OEM HEPA Air Filter Silicone Gel High-Efficiency Sealing

NewsMay.20,2025

-

OEM PLKJ-20 Filter Paper Pore Size Tester Precision Measurement

NewsMay.19,2025

-

Affordable PLNP-1 Bursting Strength Tester Low-Cost & Reliable

NewsMay.19,2025

-

Premium Toyota Air Filter Machines OEM Suppliers & Manufacturers

NewsMay.19,2025

-

OEM Truck Air Filters Machine Production Line - Custom Solutions

NewsMay.18,2025