መስከ . 26, 2024 08:02 Back to list

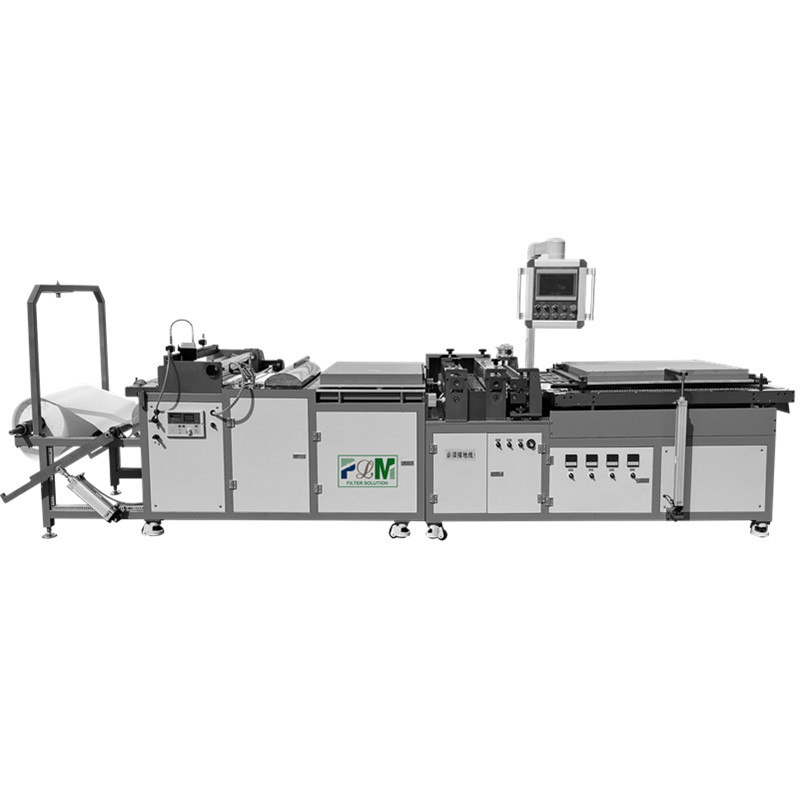

pllw-600/1000/1250 expanded mesh making machine supplier

Understanding the PLLW-600/1000/1250 Expanded Mesh Making Machine A Guide for Suppliers

In the rapidly evolving industrial landscape, the demand for efficient and high-quality manufacturing equipment has never been greater. Among the various machines that play a crucial role in the production of expanded metal mesh, the PLLW-600/1000/1250 expanded mesh making machine stands out for its versatility and efficiency. This article explores the features, benefits, and procurement considerations for suppliers looking to invest in this cutting-edge equipment.

What is an Expanded Mesh Making Machine?

Expanded mesh making machines are specialized equipment designed to produce expanded metal sheets from solid metal sheets through a unique process. The sheet metal is slitted and then stretched to create a mesh-like pattern, which can be adjusted according to specific requirements. The PLLW series, encompassing the PLLW-600, PLLW-1000, and PLLW-1250 models, caters to varying production needs, allowing suppliers to select the most suitable option for their operations.

Key Features of PLLW-600/1000/1250 Models

1. Production Capacity The PLLW series is known for its impressive production capacity. Whether it's the PLLW-600, which operates efficiently for smaller productions, or the larger PLLW-1000 and PLLW-1250 models designed for high-volume output, suppliers can choose a machine that aligns with their business scale and demand.

2. Adjustable Mesh Size One of the most notable features of the PLLW machines is the ability to produce various mesh sizes and patterns. Suppliers can customize the mesh to meet client specifications, enhancing their service offering.

3. Robust Construction These machines are built with high-quality materials to ensure durability and reliability. The structural integrity of the PLLW series means they can withstand the rigors of continuous operation, making them a long-term investment for any supplier.

4. Ease of Operation With user-friendly controls and interfaces, the PLLW machines allow operators with varying skill levels to run them effectively. This ease of use reduces training time and enhances productivity.

5. Energy Efficiency In an era where sustainability and operational costs are paramount, the PLLW-600/1000/1250 series boasts energy-efficient designs that help suppliers reduce their operational expenses while minimizing their carbon footprint.

Benefits for Suppliers

Investing in the PLLW series expanded mesh making machines provides several advantages for suppliers

pllw-600/1000/1250 expanded mesh making machine supplier

1. Meeting Customer Needs With the ability to produce custom mesh dimensions and patterns, suppliers can cater to a diverse clientele across various industries, including construction, automotive, and mining.

2. Competitive Edge The high production capacity and quality output of the PLLW machines enable suppliers to fulfill large orders promptly, giving them a competitive advantage in the market.

3. Profitability By enhancing operational efficiency and reducing production time, suppliers can improve their profit margins. The machine's durability also means lower maintenance costs over its lifespan.

4. Innovative Application The expanded metal produced by these machines can be used in an array of applications, from architectural elements to security fencing. This versatility opens up new business opportunities for suppliers.

Procurement Considerations

When looking to procure a PLLW-600/1000/1250 expanded mesh making machine, suppliers should consider the following

1. Manufacturer Reputation Choose a reputable manufacturer with a track record of producing reliable and efficient machines. Reading customer reviews and seeking testimonials can provide insights into the manufacturer's reliability.

2. Service and Support Ensure that the manufacturer offers excellent after-sales support, including maintenance services and availability of spare parts. This support will be crucial for minimizing downtime.

3. Training Some manufacturers provide training for operators, which can be invaluable in ensuring that the machine is used effectively and safely.

4. Cost and Financing Options Evaluate the total cost of ownership, including initial purchase price, maintenance, and operational costs. Explore financing options if necessary to make the acquisition more manageable.

Conclusion

The PLLW-600/1000/1250 expanded mesh making machine represents a significant advancement in manufacturing technology for expanded metal mesh. For suppliers, investing in such machinery not only enhances production capabilities but also ensures they stay competitive in a demanding market. By understanding the features, benefits, and considerations surrounding these machines, suppliers can make informed decisions that foster growth and innovation in their operations.

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025