снеж . 12, 2024 10:52 Back to list

deep fryer oil filter machine manufacturers

Exploring Deep Fryer Oil Filter Machine Manufacturers

In the culinary world, the efficiency and quality of frying processes can significantly impact the overall dining experience. One of the key factors in achieving crispy, delicious fried foods is the quality of the oil used in deep frying. Over time, frying oil degrades due to food particles, carbon build-up, and moisture. This is where deep fryer oil filter machines come into play, offering a solution for maintaining oil quality and extending its lifespan. As a result, the demand for deep fryer oil filter machine manufacturers has grown considerably across various sectors, from restaurants to food processing plants.

The Importance of Oil Filtration in Frying

Deep fryer oil filter machines are designed to remove impurities and contaminants from used frying oil. By filtering the oil, these machines help in maintaining its quality, thereby ensuring the food retains its flavor and safety for consumption. Additionally, using filtered oil can reduce the frequency of oil replacement, which not only saves costs but also minimizes waste, making it an environmentally friendly option.

The ability to reuse oil multiple times means that businesses can significantly cut down on their operational costs while also improving the quality of their fried products. Common impurities removed by these machines include carbon particulates, sediment, and remnants of the fried food.

Key Features of Deep Fryer Oil Filter Machines

Manufacturers of deep fryer oil filter machines employ sophisticated technology to enhance the filtration process. Key features to look for include

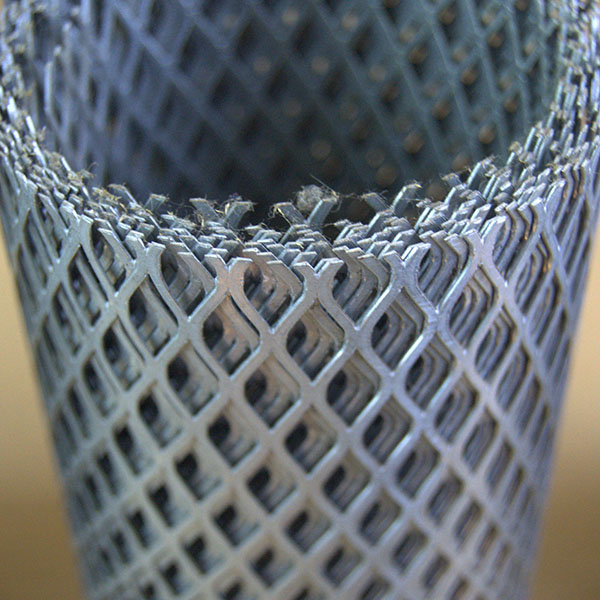

2. Multi-Stage Filtration Advanced systems use multiple stages of filtration to effectively remove a wide range of contaminants, ensuring that the oil is as clean as possible.

deep fryer oil filter machine manufacturers

3. User-Friendly Design Easy-to-use interfaces and straightforward operation are essential for busy kitchen staff who may not have time for complex procedures.

4. Size and Portability Depending on the volume of frying involved, manufacturers offer various sizes of machines to suit different business needs. Compact models are particularly useful for establishments with limited kitchen space.

5. Durability and Maintenance Reliable manufacturers produce machines that are built to last with materials that can withstand the rigors of regular use. Ease of maintenance is also crucial to prolong the machine's lifespan.

Choosing the Right Manufacturer

When selecting a deep fryer oil filter machine manufacturer, businesses should consider factors such as product range, customer support, and warranty options. It can be advantageous to partner with a manufacturer that specializes in commercial kitchen equipment, as they often have extensive knowledge of industry needs and can provide tailored solutions.

Reviews and testimonials from other businesses can also provide valuable insights into a manufacturer's reliability and the performance of their machines. Additionally, attending trade shows and expositions related to the catering and food processing industry can offer a hands-on comparison of different manufacturers and their offerings.

Conclusion

In conclusion, deep fryer oil filter machines play a pivotal role in enhancing the quality and longevity of frying oil, directly impacting the taste and safety of fried foods. As the demand for high-quality fried items continues to rise, the importance of efficient oil filtration cannot be overstated. By selecting the right manufacturer of these machines, businesses can ensure that they maintain the highest standards in their frying processes, ultimately leading to satisfied customers and a thriving culinary enterprise.

-

CE Certified Coffee Filter Paper Rolls Safe & Eco-Friendly

NewsMay.25,2025

-

OEM PLPB-1 Filter Element Air Bubble Tester Precision Quality Testing

NewsMay.25,2025

-

High Efficiency Air Filter Paper Premium Quality & Durability

NewsMay.24,2025

-

Washable G4 Air Filter Material - Durable & Reusable Air Filters

NewsMay.24,2025

-

Premium Plain Filter Paper Durable Lab & Industrial Solutions

NewsMay.23,2025

-

Best PLAG-461E Digital Filter Paper Porosity Tester Accurate & Reliable

NewsMay.23,2025