ян. . 06, 2025 11:19 Back to list

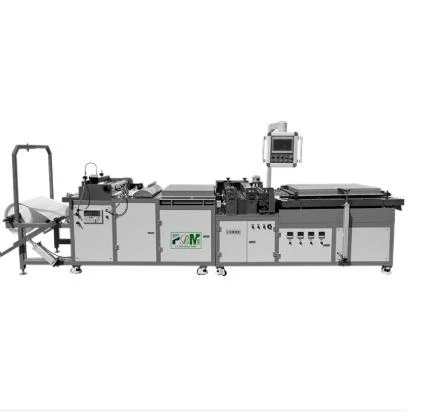

filter manufacture machine

In the intricate world of industrial engineering, the manufacture of filters stands as a pivotal process in many sectors, including automotive, water treatment, and air purification. Central to this process is the filter manufacture machine, an innovation that combines precision and efficiency. Anyone familiar with industrial manufacture will testify to the machine's role in defining the quality and safety of the filters we rely on daily.

Experience in handling a filter manufacture machine reveals that the intricacies involved are not for the untrained eye. From a first-hand perspective, the operation requires a synergy between skilled technicians and advanced technology. Technicians need to be adept at configuring the machine settings, understanding the specifics of the material being used, and monitoring the quality of the output. Such proficiency ensures that every filter produced meets stringent quality standards, something only years of hands-on experience can guarantee.

Expertise in the field of filter manufacturing does not develop overnight. A diverse understanding of different filtration needs, material science, and engineering principles is crucial. Being an expert involves not just knowing how to operate the machine, but also understanding the science behind filtration. The choice of materials, the design of the filter, and the environmental considerations all play a critical role. Professionals in this domain continuously update their knowledge to keep pace with technological advancements and regulatory changes, ensuring that each produced filter aligns with the latest industry standards.

An authoritative insight into filter manufacture machines underscores their importance in guaranteeing public health and safety. Filters produced are used across various essential services, from ensuring clean air in urban environments to maintaining water purity. Consequently, the efficacy of these filters can have wide-ranging impacts, emphasizing the need for precise manufacturing processes. Authority in this field stems from not just operational expertise but also a commitment to ongoing research and development. Companies that invest heavily in state-of-the-art machinery and skilled workforce establish themselves as leaders in the filtration industry.

Trustworthiness in filter manufacturing is non-negotiable. The stakes are high, with the potential consequences of malfunctioning filters ranging from minor inconveniences to serious health hazards. Consumers and industrial clients need to trust that the filters they install will perform reliably over their expected lifespan. This trust is built through consistent production quality, rigorous testing protocols, and compliance with international standards. Manufacturers that have stringent quality assurance processes and transparent reporting mechanisms typically enjoy greater trust from their clients.

In conclusion, the filter manufacture machine is a cornerstone of effective filtration solutions. The confluence of cutting-edge technology and skilled human intervention ensures that the filters used in critical applications are safe, reliable, and efficient. The role of experience, expertise, authority, and trust cannot be understated in this context, as each element contributes to the overall reliability of the filter manufacturing process. It is through this meticulous approach that manufacturers can assure clients of the integrity and functionality of their products, thereby securing their place in the competitive world of industrial manufacturing.

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025

-

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

NewsAug.18,2025

-

PLAB-6 Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Filtering

NewsAug.17,2025