дек. . 18, 2024 23:55 Back to list

Selection of Fume Filter Cartridge Materials for Effective Air Pollution Control

Understanding Fume Filter Cartridge Filter Materials An Essential Guide

In today’s industrial landscape, the importance of air quality cannot be overstated. Factories, workshops, and other industrial facilities often deal with hazardous fumes and particles that pose serious health risks. This is where fume filter cartridge filters come into play. They serve a crucial role in maintaining clean air by effectively capturing and containing particulates and harmful vapors. In this article, we will explore the different materials used in fume filter cartridge filters, their features, and their applications.

What Are Fume Filter Cartridge Filters?

Fume filter cartridge filters are specialized filtration devices designed to remove airborne contaminants from industrial environments. These filters are housed in cylindrical cartridges, making them efficient and easy to replace. They are commonly used in processes like welding, painting, and chemical manufacturing, where harmful fumes and particulates are generated. The type of filter material used can significantly affect the filter's performance, efficiency, and lifespan.

Common Materials Used in Fume Filter Cartridges

1. Fiberglass Fiberglass is a popular material for fume filter cartridges due to its durability and effective filtration capabilities. It can withstand high temperatures and is resistant to many chemicals, making it ideal for harsh environments. Fiberglass filters are typically used in applications that involve high levels of dust and particulate matter.

2. Polyester Polyester filter media is known for its excellent moisture resistance and chemical compatibility. It is often used in environments where humidity levels are high. Polyester filters tend to be more affordable than fiberglass and still provide reliable performance for various applications, such as air filtration in spray booths.

3. PTFE (Polytetrafluoroethylene) PTFE filters are highly resistant to chemicals and can withstand extreme temperatures. This material is particularly effective in applications involving corrosive substances, making it an excellent choice for industries such as pharmaceuticals and chemical processing. PTFE filters are also known for their self-cleaning properties, which enhance their lifespan and reduce maintenance time.

4. Carbon-Impregnated Media For applications that generate odor or require the removal of specific gaseous contaminants, carbon-impregnated filter materials are utilized. The activated carbon within the filter absorbs volatile organic compounds (VOCs) and other harmful gases, ensuring that the air released back into the environment is clean and safe.

fume filter cartridge filter material products

5. Pleated Filter Media By increasing the surface area of the filter, pleated designs enhance dust-holding capacity and lifespan. Pleated filters can be made with various materials, including fiberglass and polyester, allowing for versatility in different applications. They provide greater efficiency and longer service intervals, reducing replacement costs in the long run.

Key Features to Consider

When selecting fume filter cartridge filters, there are several features that should be evaluated

- Filtration Efficiency A high-efficiency filtration media is essential for capturing fine particles and aerosols. Look for filters with a high Minimum Efficiency Reporting Value (MERV) rating.

- Temperature Range Depending on the application, filters must withstand varying temperatures. Knowing the operational temperature range will help ensure that the chosen filter is suitable for your specific needs.

- Chemical Compatibility Assessing the types of chemicals present in the environment will guide you in selecting materials that won’t degrade or become ineffective when exposed to those substances.

- Maintenance Requirements Some filter materials require more frequent replacement or maintenance than others. Understanding your facility's operational demands will help streamline the maintenance process and reduce downtime.

Conclusion

Fume filter cartridge filters are integral to manufacturing processes where air quality is a concern. Understanding the various materials used in these filters is crucial for choosing the right one for your application. Whether you opt for fiberglass, polyester, PTFE, carbon-impregnated media, or pleated designs, each material has unique characteristics that cater to specific environments and contaminants. By selecting the appropriate filter, you can ensure a safe working environment while also complying with environmental regulations. Investing in high-quality fume filter cartridge filters not only protects workers' health but also enhances the overall efficiency and sustainability of industrial operations.

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

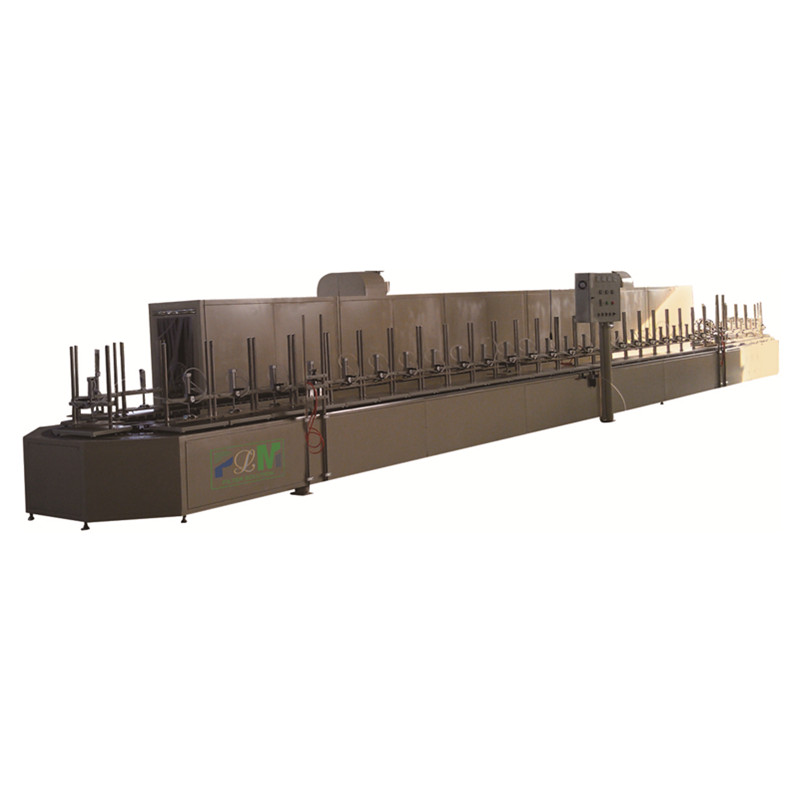

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025