Dis . 23, 2024 03:38 Back to list

oem car pu air filter production line

OEM Car PU Air Filter Production Line Revolutionizing Automotive Manufacturing

In the automotive industry, maintaining optimal performance and efficiency of vehicles is paramount. One critical component that plays a vital role in achieving this is the air filter. Among various types of air filters, polyurethane (PU) air filters have gained significant traction due to their durability and efficiency in trapping airborne contaminants. The OEM (Original Equipment Manufacturer) car PU air filter production line represents a sophisticated approach to manufacturing these essential components, enhancing both quality and productivity.

Understanding PU Air Filters

PU air filters are designed to provide superior filtration performance while ensuring longevity. Unlike traditional paper filters, PU air filters are constructed using a foam material that allows for greater airflow and improved filtering capabilities. This makes them particularly beneficial in environments where dust and particulate matter are prevalent. Moreover, these filters are lighter and can be molded into various shapes, making them versatile for different vehicle models.

The Production Process

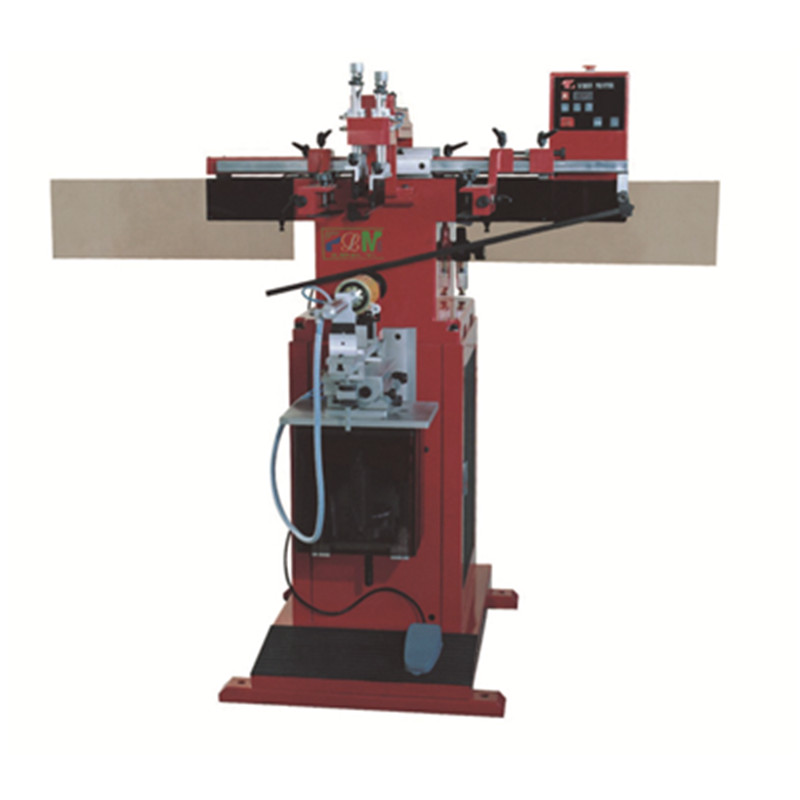

The production line for OEM car PU air filters consists of several stages, each meticulously designed to ensure high-quality output. It starts with the selection of raw materials. Quality PU foam is sourced, which is then cut and shaped according to specific dimensions required for different car models. Advanced machinery is utilized for precise cutting, guaranteeing minimal waste and optimum sizing.

Next, the foam undergoes a treatment process where it is impregnated with specialized compounds to enhance its filtering capabilities and resistance to degradation. This stage is crucial as it determines the longevity and effectiveness of the air filters.

Once the treatment is complete, the filters are assembled. This involves combining the shaped PU foam with frame materials, often made from plastic or metal. Automated systems ensure that the assembly is conducted quickly and accurately, reducing human error and increasing overall productivity.

oem car pu air filter production line

Quality Control

Quality control is a cornerstone of the OEM car PU air filter production line. Throughout the manufacturing process, filters are subjected to rigorous testing to ensure they meet industry standards and specifications. Parameters such as airflow, filtration efficiency, and durability are meticulously evaluated. Automated testing systems allow for real-time monitoring so that any abnormalities can be addressed promptly.

Benefits of the Production Line

The implementation of a specialized production line for OEM car PU air filters offers numerous advantages. Firstly, it enhances production efficiency, allowing manufacturers to produce a higher volume of filters without compromising on quality. This is particularly important in an industry where demand fluctuates based on market trends and vehicle sales.

Secondly, the ability to customize air filters for specific brands and models caters to the diverse needs of the automotive sector. This flexibility is essential for OEMs that require tailored solutions for their vehicles, ensuring better integration and performance.

Finally, a dedicated production line contributes to sustainability efforts. By utilizing advanced manufacturing technologies, waste can be minimized, and energy efficiency can be maximized, aligning with global initiatives toward greener manufacturing practices.

Conclusion

The OEM car PU air filter production line is a testament to innovation in the automotive manufacturing sector. As vehicles become increasingly sophisticated, the need for quality air filters is paramount in ensuring performance and efficiency. With advancements in production technology and a focus on quality control, this specialized production line not only meets the demands of modern vehicles but also paves the way for sustainable practices in the automotive industry. As we move forward, the importance of efficient and effective air filtration systems will continue to grow, making the investment in advanced production lines a key factor in success for manufacturers.

-

Premium Engine Oil Filter Supplier & Exporter Reliable Engine Oil Filter Service

NewsJul.04,2025

-

Wholesale PLRZ-1000N Full-Auto Hot Melt Filter Paper Bonding Machine - High Efficiency & Precision

NewsJul.04,2025

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025