Dec . 07, 2024 03:44 Back to list

Quotes on Manufacturing Machines and Their Filters for Better Production Efficiency

The Importance of Filter Manufacturing Machines A Comprehensive Overview

In today's industrial landscape, the demand for efficient filter manufacturing is at an all-time high. As industries evolve and regulations tighten regarding air and water quality, the role of filter manufacturing machines becomes increasingly vital. These machines not only enhance production efficiency but also ensure the quality of the filters produced, which are critical for a range of applications from automotive to aerospace, and water purification to pharmaceutical processes. In this article, we will explore the significance of filter manufacturing machines, their types, functions, and the factors influencing their performance.

Understanding Filter Manufacturing Machines

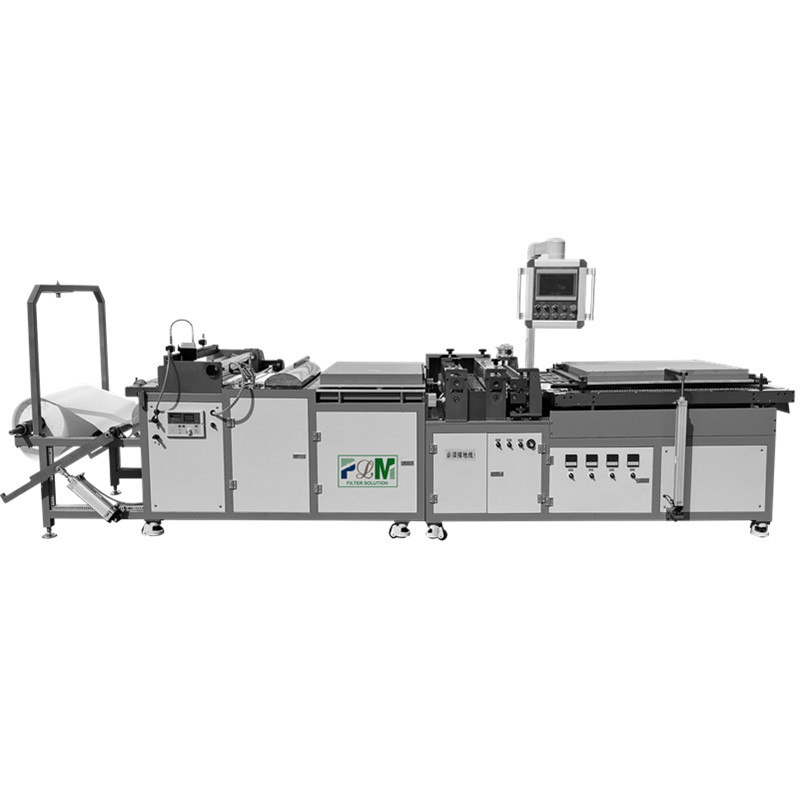

Filter manufacturing machines are specialized equipment designed to produce various types of filters, including air filters, oil filters, and water filters. These machines automate the manufacturing process, minimizing human intervention while maximizing precision and efficiency. Depending on the complexity and type of filter being produced, the machines can vary significantly in terms of design, capability, and output.

The basic functions of these machines include cutting, folding, pleating, and assembling the filter media, which is often made from various types of materials including paper, synthetic fibers, and metal mesh. Advanced machines may also integrate inspection systems to ensure the quality of the filters meets industry standards.

Types of Filter Manufacturing Machines

1. Cutting Machines These are essential for cutting raw filter materials into precise dimensions. Advanced cutting machines can perform high-speed operations, which is crucial for large-scale production.

2. Pleating Machines Pleating is a critical process in filter manufacturing as it increases the surface area of the filter medium, enhancing its efficiency. Pleating machines can produce various pleat styles, including accordion, radial, and parallel pleats.

3. Assembly Machines After the filter media has been cut and pleated, assembly machines join the components, often adding frames and seals to create a finished product. Automation in this stage reduces labor costs and increases production speed.

4. Testing and Inspection Machines Quality control is paramount in filter manufacturing. Testing machines analyze the performance of the filters under different conditions to ensure they meet regulatory standards and customer expectations.

filter manufacture machine quotes

Factors Influencing Filter Manufacturing Machine Performance

The performance of filter manufacturing machines can be influenced by various factors, including

- Material Quality The quality of raw materials used in filter production directly impacts the performance and durability of the filters. High-quality materials contribute to longer lifespans and better filtration efficiency.

- Machine Maintenance Regular maintenance of manufacturing machines is essential to ensure their longevity and operational efficiency. Neglect can lead to breakdowns and decreased production capabilities.

- Technological Advancements Innovations in technology can lead to significant improvements in filter manufacturing processes. Automated systems, robotics, and AI can enhance precision and reduce operational costs.

- Training and Expertise Operators must be properly trained to handle sophisticated machinery. Their expertise can determine the quality of the production output and the efficiency of the manufacturing process.

Conclusion

As the demand for efficient and high-quality filters continues to rise, the importance of advanced filter manufacturing machines cannot be overstated. These machines play a crucial role in ensuring that industries comply with stringent environmental regulations while meeting the needs of consumers for clean air and water.

Investing in state-of-the-art filter manufacturing machines not only enhances production capabilities but also strengthens a company's market position by ensuring reliability and quality. As technology progresses, we can expect further advancements in filter manufacturing processes that will drive efficiency, reduce environmental impact, and ultimately lead to better filtration solutions across various sectors. In essence, the machinery behind filter production is not just a tool but a cornerstone of a healthier and sustainable future.

-

Premium Coffee Filter Rolling Paper: Fine Mesh for Smooth DIY

NewsAug.27,2025

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025