Οκτ . 14, 2024 21:30 Back to list

OEM Japanese Car Air Filter Manufacturing Equipment for Efficient Production

The Importance of OEM Japanese Car Air Filter Machines

In the world of automotive manufacturing, the significance of Original Equipment Manufacturer (OEM) parts cannot be overstated. For Japanese cars, known for their precision engineering and reliability, OEM components play a crucial role in maintaining vehicle performance and longevity. Among these components, the air filter is vital for ensuring clean airflow to the engine, which directly impacts fuel efficiency and emissions. This is where OEM Japanese car air filter machines come into play, providing the necessary tools for the production of high-quality air filters tailored specifically for Japanese automotive brands.

Understanding OEM and Its Importance

OEM refers to companies that manufacture parts that are used in the original assembly of vehicles. These components are often produced to the specific standards set by the vehicle manufacturers, ensuring compatibility and performance. The reason OEM parts are preferred over aftermarket alternatives lies in their reliability and adherence to strict quality control measures. Particularly in Japanese vehicles, which typically embrace advanced engine technologies and designs, using OEM components, like air filters, is essential to achieving optimal performance.

The Role of Air Filters

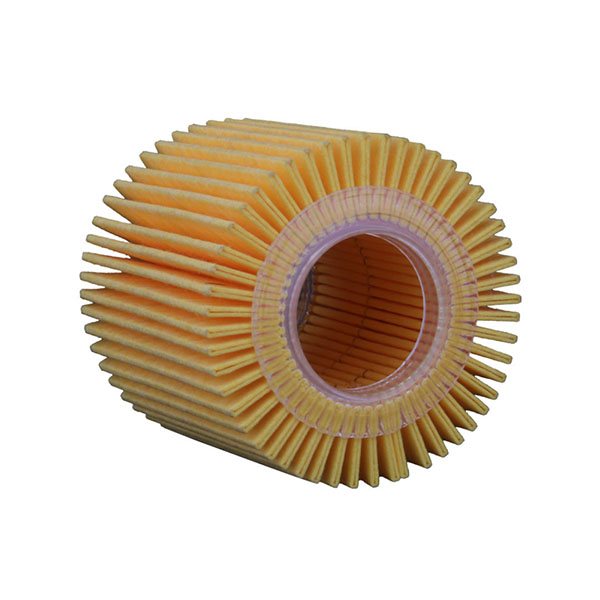

Air filters serve a critical function in a vehicle's engine operation. They prevent dirt, debris, and other contaminants from entering the engine, thereby ensuring that the air-fuel mixture remains efficient. A clean air filter contributes to smoother engine performance, better fuel economy, and reduced emissions. Conversely, a clogged air filter can lead to decreased engine power, increased fuel consumption, and higher levels of harmful emissions. Given the rising concerns about environmental impact and fuel efficiency, the importance of a quality air filter cannot be ignored.

OEM Japanese Car Air Filter Machines

To produce high-quality OEM air filters for Japanese vehicles, specialized machinery is employed. OEM Japanese car air filter machines are designed to manufacture filters that meet rigorous specifications. These machines utilize advanced technologies and methods to ensure precision and consistency in every filter produced.

oem japanese car air filter machine

1. Material Selection The manufacturing process begins with the selection of the right materials. OEM machines are equipped to handle various filter media, such as foam, paper, and synthetic fibers, each chosen based on the specific requirements of the vehicle model.

2. Production Techniques Modern air filter machines integrate automated processes that enhance efficiency and reduce human error. From cutting the filter media to shaping and assembling the components, these machines ensure that every step adheres to the strictest quality standards.

3. Testing and Quality Control After production, OEM air filters undergo rigorous testing to guarantee their performance. Machines often include quality control mechanisms that check for airflow resistance, filtration efficiency, and structural integrity. This attention to detail in the production process ensures that the air filters will perform optimally in Japanese vehicles.

4. Innovation and Adaptation The automotive industry is constantly evolving, with manufacturers incorporating new technologies and design features. OEM Japanese car air filter machines are designed to adapt to these changes, allowing manufacturers to quickly adjust their production lines to meet the latest standards and requirements.

Conclusion

In summary, OEM Japanese car air filter machines represent an essential investment in the automotive sector, particularly for manufacturers focused on producing reliable and efficient vehicles. By employing specialized machinery for air filter production, companies can ensure that their products maintain the same quality and performance as the original parts designed by the vehicle manufacturers. This not only enhances the vehicles' overall efficiency and lifespan but also contributes to meeting environmental regulations through improved emissions standards.

As the automotive industry continues to innovate, the role of OEM parts and the machines that produce them will remain crucial. The commitment to quality, performance, and compliance with industry standards makes OEM Japanese car air filter machines a vital component in the production of vehicles that drivers can trust on the road.

-

Wholesale Eco Oil Filter Making Machines High-Efficiency & Affordable

NewsMay.10,2025

-

Activated Carbon Filter Sheets Odor Removal & Air Purification Solutions

NewsMay.10,2025

-

MERV 8 Pleated AC Furnace Air Filters High Efficiency & Durable

NewsMay.10,2025

-

OEM ISF2.8 Oil-Water Separator Fuel Filter High-Efficiency Solution

NewsMay.10,2025

-

Affordable PLQF-130 Thick Ieon Plate Seaming Machine Heavy-Duty & Efficient

NewsMay.10,2025

-

Air Filter Plastic Frame Suppliers Durable A-Frame Solutions

NewsMay.09,2025