Sep . 02, 2025 01:40 Back to list

Premium Active Carbon Air Filter for Purifiers - Odor & VOC Removal

Navigating Advanced Air Purification with Activated Carbon Technology for B2B Applications

In industrial and commercial environments, maintaining superior air quality is not merely a matter of comfort but a critical factor in operational efficiency, regulatory compliance, and personnel health. The demand for sophisticated air filtration solutions, capable of addressing a wide spectrum of airborne contaminants, continues to escalate. At the forefront of this evolution is the active carbon air filter for air purifier, a technology indispensable for removing volatile organic compounds (VOCs), odors, and hazardous gaseous pollutants that traditional particulate filters cannot capture. This comprehensive guide delves into the intricate details of activated carbon filtration, its multifaceted applications, and its pivotal role in shaping cleaner, safer B2B spaces.

Industry Trends and Market Dynamics in Air Filtration

The global air purification market is experiencing robust growth, driven by increasing industrialization, urbanization, and a heightened awareness of indoor air quality's impact on health and productivity. Regulatory bodies worldwide are imposing stricter emission standards and workplace safety guidelines, compelling businesses to invest in advanced filtration technologies. This trend extends beyond typical HVAC applications to specialized sectors requiring precise environmental control. For instance, while a fuel filter for caterpillar truck engine addresses combustion system purity and an oil filter fit for outback legacy svx car ensures engine longevity, the challenges associated with airborne molecular contamination are distinct and require specialized solutions like the active carbon air filter for air purifier.

Key market drivers include:

- Rising Health Concerns: Increased prevalence of respiratory illnesses necessitates cleaner air in commercial buildings, healthcare facilities, and educational institutions.

- Industrial Emissions Control: Stricter environmental regulations demand effective removal of gaseous pollutants from manufacturing processes.

- Technological Advancements: Innovations in filter media, filter design, and smart air purification systems enhance efficiency and extend service life.

- Energy Efficiency Imperatives: Demand for filters that maintain high performance while minimizing pressure drop and energy consumption for HVAC systems.

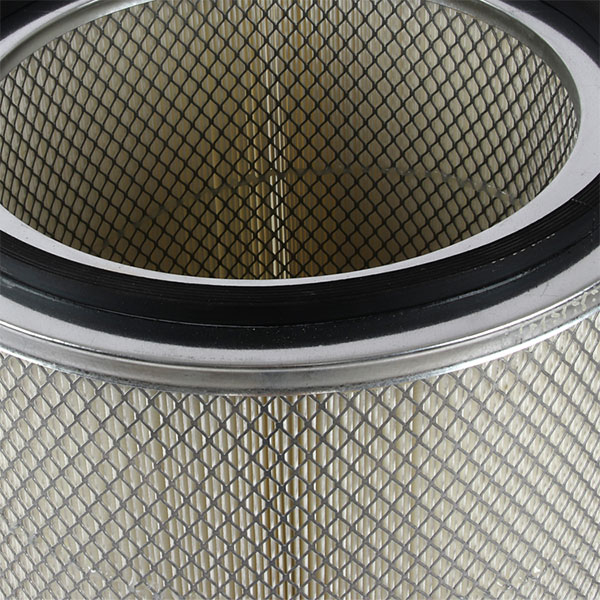

An intricate structure designed for optimal air purification.

Technical Specifications and Principles of Activated Carbon Filtration

The efficacy of an active carbon air filter for air purifier stems from the unique properties of activated carbon, a highly porous material produced from various organic sources such as coal, wood, or coconut shells. The activation process creates millions of microscopic pores, significantly increasing the surface area for adsorption. This adsorption phenomenon involves molecular attraction, where gaseous contaminants adhere to the internal surfaces of the carbon material.

Key Technical Parameters:

- Adsorption Capacity: Measured in mg of contaminant per gram of carbon, indicating the amount of pollutant the filter can hold before saturation.

- Pore Size Distribution: Critical for targeting specific molecular sizes; micropores (0-2 nm) and mesopores (2-50 nm) are crucial for VOCs.

- Bed Depth and Contact Time: Deeper carbon beds and longer air contact times generally result in higher removal efficiency.

- Pressure Drop: A measure of resistance to airflow, directly impacting energy consumption. Optimized filter design minimizes pressure drop while maximizing efficiency.

- Impregnation: Some activated carbons are impregnated with chemicals (e.g., potassium permanganate) to enhance their ability to react with and remove specific compounds like hydrogen sulfide (H2S) or formaldehyde.

Product Specification Table: Industrial Activated Carbon Air Filter

| Parameter | Typical Value / Description |

|---|---|

| Filter Media | High-grade Activated Granular Carbon (Coconut Shell or Coal-based) |

| Media Type | Pelletized or Granular, optionally impregnated |

| Activated Carbon Content | ≥ 90% (by weight) |

| Iodine Number (Adsorption Capacity) | ≥ 1000 mg/g (ASTM D4607) |

| Benzene Adsorption Rate | ≥ 25% (Weight % adsorbed) |

| ASH Content | ≤ 5% |

| Service Life (Typical) | 6-18 months, depending on contaminant load and concentration |

| Operating Temperature Range | -20°C to 80°C |

| Relative Humidity Range | 5% - 95% (Non-condensing) |

| Standard Compliance | ISO 16890, ASHRAE 52.2, EN 1822 |

Components of an advanced activated carbon air filter.

Manufacturing Process Flow for Active Carbon Air Filters

The production of a high-performance active carbon air filter for air purifier is a multi-stage process, meticulously controlled to ensure consistent quality and optimal adsorption characteristics. From raw material selection to final assembly, each step is critical.

Schematic Steps of Production:

-

Raw Material Procurement & Pre-treatment:

High-quality carbonaceous raw materials (e.g., coconut shells, wood, coal) are sourced. These are then crushed, sieved, and washed to remove impurities and control particle size distribution, essential for uniform activation.

Material Focus: Consistent quality and purity are paramount for subsequent activation. -

Carbonization (Pyrolysis):

The pre-treated material undergoes pyrolysis in an inert atmosphere at temperatures typically ranging from 400°C to 800°C. This process removes volatile organic compounds and converts the material into char, developing a rudimentary pore structure.

Process Insight: This step is analogous to initial casting in metallurgy, forming the basic structure. -

Activation (Physical or Chemical):

Physical Activation: Char is treated with oxidizing gases (steam or CO2) at high temperatures (800°C-1100°C) to selectively burn off carbon atoms, expanding the pore structure and increasing surface area.

Chemical Activation: Char is impregnated with activating agents (e.g., phosphoric acid, zinc chloride) and heated at lower temperatures (400°C-600°C), followed by washing to remove the chemical. This method often results in a higher yield and more developed pore structure.Technical Advantage: This is where the filter gains its exceptional adsorption capabilities. Controlled activation is crucial, similar to precision CNC machining for mechanical parts. -

Grinding, Sieving & Washing:

The activated carbon is ground to the desired particle size, sieved for uniformity, and thoroughly washed to remove residual chemicals and fine particles. Drying follows to achieve optimal moisture content.

-

Impregnation (Optional):

For specific applications, activated carbon may be impregnated with catalysts or chemical reactants (e.g., potassium iodide, phosphoric acid) to enhance removal of particular chemical species, a process similar to surface treatments in specialized forging operations.

-

Filter Element Assembly:

The processed activated carbon is then integrated into various filter element designs. This can include filling trays, pleating into media with support layers (e.g., fiberglass or synthetic media for particulate pre-filtration), or forming honeycomb structures like a honeycomb activated carbon filter. The filter frame, often made of galvanized steel, aluminum, or robust plastic, provides structural integrity.

-

Quality Control & Testing:

Each batch and finished filter undergoes rigorous testing. This includes:

- Adsorption Capacity Tests: Using test gases (e.g., butane, carbon tetrachloride) per ASTM D3467.

- Pressure Drop Measurement: Ensuring minimal airflow resistance.

- Airflow Uniformity Tests: Verifying even distribution of air through the filter media.

- Structural Integrity Tests: To meet standards like ISO 16890 and ASHRAE 52.2.

Testing Standards: Adherence to international standards like ISO and ANSI ensures product reliability and performance consistency. Service life is projected based on these rigorous tests and expected contaminant loads.

An array of activated carbon filter media.

Application Scenarios and Target Industries

The versatility of the active carbon air filter for air purifier makes it indispensable across a broad spectrum of industrial and commercial applications where gaseous pollutants pose significant challenges.

-

HVAC Systems in Commercial & Institutional Buildings:

From offices and schools to airports and hotels, these filters remove odors, VOCs from building materials, cleaning agents, and occupants, ensuring a healthier and more pleasant indoor environment. This significantly outperforms standard particulate filters like a merv 8 pleated ac furnace air filter in terms of odor and gaseous contaminant removal.

-

Industrial Process Odor Control:

Crucial in industries such as wastewater treatment plants (water supply & drainage), food processing, rendering plants, and chemical manufacturing, where malodorous compounds like H2S, ammonia, and mercaptans are prevalent. They prevent off-site odor migration and comply with air quality regulations.

-

Data Centers & Electronics Manufacturing:

Protect sensitive electronic equipment from corrosive gases (e.g., sulfur oxides, chlorine) that can cause costly system failures and downtime. Precision air purification is vital here.

-

Healthcare Facilities & Laboratories:

Remove chemical fumes, anesthetic gases, and biological odors, creating sterile and safe environments for patients and staff. Compliance with standards like ISO and FDA regulations is paramount.

-

Museums & Archives:

Protect delicate artifacts and documents from degradation caused by acidic gases and pollutants in the air.

-

Petrochemical & Metallurgy Industries:

In these challenging environments, air filters remove corrosive gases and fumes, protecting sensitive control room electronics and ensuring a safe breathing environment for workers. The emphasis here is on robust construction and high adsorption capacity, much like how specialized fuel filter for 6.7l diesel fd4615 are built for heavy-duty engines.

An air purification system integrating an activated carbon filter.

Technical Advantages and Performance Metrics

The inherent design and material science behind a quality active carbon air filter for air purifier offer significant technical advantages:

- Broad Spectrum Adsorption: Effective against a wide range of organic and some inorganic gaseous pollutants, including VOCs (e.g., formaldehyde, benzene), odors, acid gases, and basic gases. This is a significant upgrade from generic replacement dyson carbon hepa air filter types, which often target a narrower range of airborne contaminants.

- High Removal Efficiency: Capable of achieving 90-99% removal efficiency for targeted contaminants, depending on concentration, airflow, and filter design.

- Energy Saving: Modern designs, especially those integrating honeycomb activated carbon filter structures or optimized pleated configurations, minimize static pressure drop. This reduces the load on HVAC fans, leading to significant energy saving over the filter's service life.

- Corrosion Resistance: Filter frames and media are often engineered with materials resistant to corrosive environments, ensuring durability and extending service life in demanding industrial settings, providing superior corrosion resistance.

- Long Service Life: With proper sizing and pre-filtration (e.g., a particulate filter), activated carbon filters can last 6-18 months, reducing maintenance frequency and operational costs.

- Environmental Compliance: Enables businesses to meet strict local and international air quality standards, avoiding penalties and fostering a responsible corporate image.

Vendor Comparison and Selection Criteria

Choosing the right supplier for your activated carbon air filtration needs is paramount. While many suppliers offer filters, discerning the quality and suitability requires careful evaluation.

Key Considerations for Vendor Selection:

- Certifications & Standards: Ensure the vendor's products comply with relevant industry standards (e.g., ISO 9001 for quality management, ASHRAE 52.2, EN 1822 for filter performance). Look for FDA compliance if applicable to sensitive industries.

- Material Quality: Inquire about the source and type of activated carbon used (coconut shell, coal, wood) and its Iodine Number, which indicates adsorption capacity.

- Customization Capabilities: Can they provide filters tailored to specific dimensions, airflow requirements, or target contaminants?

- Technical Support & Expertise: A knowledgeable vendor offers pre-sale consultation and post-sale support, including system integration and maintenance guidance.

- Case Studies & References: Proven track record with reputable clients in relevant industries.

Comparison Table: Activated Carbon Filter Types

| Feature | Pelletized Granular Carbon Filter | Honeycomb Carbon Filter | Carbon Impregnated Pleated Filter |

|---|---|---|---|

| Carbon Form | Loose pellets/granules in trays/beds | Carbon-infused ceramic/paper in honeycomb matrix | Carbon powder bonded to synthetic media |

| Adsorption Capacity | Very High (Large carbon volume) | High (Optimized airflow paths) | Moderate (Lower carbon loading) |

| Pressure Drop | Moderate to High | Low to Moderate | Very Low |

| Particulate Filtration | Minimal (Requires pre-filter) | Moderate (Can be combined with particulate) | Good (Often acts as dual-purpose) |

| Service Life | Longest | Long | Shorter |

| Cost (Relative) | Highest initial, good long-term value | Moderate to High | Lowest initial, higher replacement frequency |

Precision manufacturing ensuring filter integrity.

Customized Solutions and Application Case Studies

Recognizing that no two industrial applications are identical, leading manufacturers of the active carbon air filter for air purifier offer tailored solutions. This might involve custom filter dimensions, specific carbon types (e.g., coconut shell for high VOC adsorption), or chemically impregnated carbon for targeted contaminant removal (e.g., for hydrogen sulfide in wastewater facilities or mercury vapor).

Case Study 1: Odor Control in a Large-Scale Food Processing Plant

Client: A major poultry processing facility in the Midwest, facing persistent odor complaints from neighboring communities and regulatory scrutiny for elevated ammonia and organic sulfur compound emissions.

Challenge: Existing exhaust systems used basic particulate filters, entirely ineffective against the complex mix of odorous gases. The plant required a solution with high adsorption capacity and robust performance in high-humidity conditions.

Solution: We engineered a custom filtration bank incorporating multi-stage filtration. The core of the solution included large format, deep-bed active carbon air filter for air purifier units filled with specially impregnated coconut shell activated carbon. These filters were designed to handle high airflow volumes (20,000 CFM) and operate efficiently even at 80% relative humidity. Pre-filters (MERV 13) were used to protect the carbon media from particulate loading.

Outcome: Within three months of installation, recorded odor levels at the property line dropped by over 90%, eliminating community complaints. Monitoring showed sustained removal rates of ammonia and methyl mercaptans above 95%. The solution also demonstrated energy efficiency due to optimized filter bed design, contributing to an estimated 15% reduction in fan power consumption compared to less efficient, higher-pressure-drop alternatives. The filters' service life exceeded initial projections, leading to significant operational cost savings.

Case Study 2: Protecting Sensitive Electronics in a Pulp & Paper Mill

Client: A large pulp and paper manufacturing facility struggling with frequent failures of control room electronics due to corrosive gases (sulfur dioxide, hydrogen sulfide, chlorine) inherent in their process.

Challenge: The harsh chemical environment necessitated a filtration solution that offered superior corrosion resistance and high-efficiency removal of specific corrosive gases to safeguard expensive control systems.

Solution: We designed and installed a specialized chemical filtration system for the control room's HVAC intake. This system utilized granular impregnated activated carbon filters, specifically engineered for acid gas removal, paired with robust, corrosion-resistant housings and seals. The filtration media was chosen for its high capacity against SO2 and H2S.

Outcome: Post-installation, the facility reported a dramatic reduction in electronic component failures within the control room. Downtime related to corrosion-induced issues was virtually eliminated. Air quality monitoring inside the control room confirmed that corrosive gas levels were consistently below ISA (Instrumentation, Systems, and Automation Society) G1 guidelines for sensitive electronics. The filter media's service life was estimated at 12-15 months under these conditions, demonstrating excellent cost-effectiveness over time.

Advanced testing ensures peak performance for all filters.

Ensuring Trustworthiness: FAQs, Lead Times, Warranty, and Support

Transparency and reliability are core tenets of our commitment to B2B clients. We provide comprehensive support throughout the product lifecycle.

Frequently Asked Questions (FAQs)

Q1: How do I know when to replace my active carbon air filter for air purifier?

A1: Unlike particulate filters where pressure drop indicates saturation, activated carbon filters lose efficiency as the carbon becomes saturated with adsorbed gases, typically without a significant change in pressure drop. Monitoring air quality downstream with specific gas sensors is the most accurate method. Alternatively, establishing a regular replacement schedule based on typical service life for your specific application (e.g., 6-18 months) is common practice.

Q2: Can activated carbon filters remove all types of gaseous pollutants?

A2: While highly effective against a broad range of organic compounds and some inorganic gases, activated carbon has limitations. Very small, non-polar molecules (like carbon monoxide, CO2) are poorly adsorbed. Specialized impregnated carbons are used for certain inorganic gases. For applications requiring filtration of compressed air, systems like an rts aliexpress way compressed air filter or an isf2 8 oil-water separator fuel filter would address different types of contaminants in different media.

Q3: What role does a pre-filter play with an activated carbon filter?

A3: Pre-filters are crucial. They capture particulate matter (dust, pollen, spores) before it reaches the activated carbon filter. This prevents the carbon's pores from becoming clogged by particles, thus preserving the carbon's adsorption capacity and extending the service life of the more expensive activated carbon filter. A common combination might involve a high-efficiency particulate filter followed by the carbon filter, just as an 37010 - auto car engine oil filter works in conjunction with air filters in an automotive system.

Lead Time & Fulfillment

Standard lead time for our range of activated carbon air filters is typically 2-4 weeks, depending on order volume and specific product configurations. Customized solutions may require additional time for design and manufacturing. We leverage efficient logistics networks to ensure timely and secure global fulfillment. Expedited options are available upon request for urgent requirements.

Warranty Commitments

All our active carbon air filter for air purifier products are backed by a comprehensive warranty against manufacturing defects and material failures. The specific warranty period varies by product series, typically ranging from 12 to 24 months from the date of purchase. Our commitment to quality ensures reliability and peace of mind for our clients. Full warranty terms are available upon request.

Customer Support Information

Our dedicated technical customer support team is available to assist with product selection, installation guidance, troubleshooting, and maintenance inquiries. We offer multilingual support and are reachable via phone, email, or our online portal. We pride ourselves on rapid response times and expert advice to ensure your filtration systems operate optimally.

References

- U.S. Environmental Protection Agency (EPA). (2023). Indoor Air Quality. www.epa.gov/indoor-air-quality

- ASHRAE Standard 52.2-2017: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. www.ashrae.org

- International Organization for Standardization (ISO). (2018). ISO 16890-1:2016, Air filters for general ventilation - Part 1: Technical specifications, requirements and classification system based on particulate matter efficiency (ePM). www.iso.org

- American Society for Testing and Materials (ASTM). (Various). Standards for Activated Carbon. www.astm.org

- The Adsorption Handbook: Activated Carbon, Catalytic Carbon. (Various Publishers and Authors).

active carbon air filter for air purifier – Odor/VOC Control

NewsNov.17,2025Replacement Dyson Carbon HEPA Air Filter – High Efficiency

NewsNov.17,2025Active Carbon Air Filter for Air Purifier | High Adsorption

NewsNov.17,2025Active Carbon Air Filter for Air Purifier | Odor & VOC Control

NewsNov.17,2025Active Carbon Air Filter for Air Purifier | Odor & VOC

NewsNov.17,2025Sintered Porous Metal Filter Tube Cup | 5 Micron, SS316L

NewsNov.11,2025