nov. . 15, 2024 14:42 Back to list

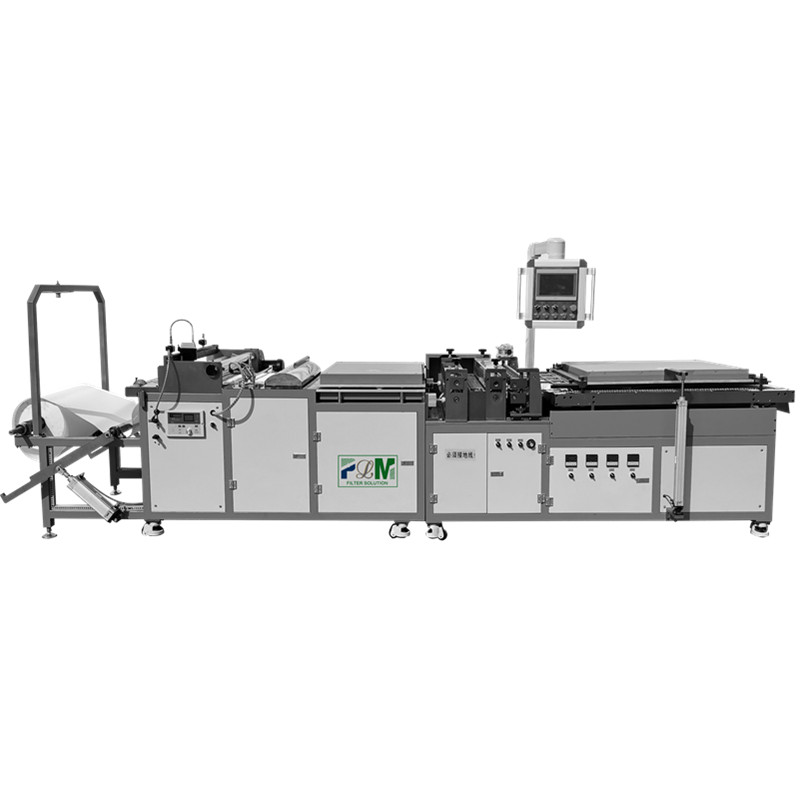

spiral filter core making machine

The Spiral Filter Core Making Machine Revolutionizing Filtration Technology

In recent years, the demand for efficient filtration systems has grown dramatically across various industries, from water treatment to air purification. At the heart of these systems often lies the spiral filter core—a crucial component that significantly enhances filtration performance. To meet this increasing demand, the spiral filter core making machine has emerged as a groundbreaking solution, streamlining the production process and improving product quality.

Understanding the Spiral Filter Core

The spiral filter core is designed to maximize surface area while minimizing flow resistance. This innovative design allows for enhanced filtration efficiency, capturing particles more effectively than traditional flat or cylindrical filters. The unique spiral configuration increases the contact area between the fluid and the filter material, leading to superior contaminant removal. As industries look to improve environmental sustainability and meet stringent regulations, the demand for high-quality spiral filter cores continues to rise.

The Role of the Spiral Filter Core Making Machine

The spiral filter core making machine is a specialized piece of equipment that automates the manufacturing of these critical components. By utilizing advanced technology, it can produce spiral cores with precision and consistency. The machine typically processes various materials, including synthetic fibers and polymer composites, which can be tailored to specific filtration needs.

One of the key features of modern spiral filter core making machines is their versatility. They can be programmed to adjust the diameter, length, and pitch of the spiral, allowing manufacturers to create custom solutions for different applications. This adaptability not only meets the diverse requirements of various industries but also enables companies to respond swiftly to market demands.

spiral filter core making machine

Efficiency and Cost-Effectiveness

The introduction of spiral filter core making machines has significantly improved production efficiency. Automated processes reduce labor costs and minimize human error, leading to enhanced product consistency. Additionally, these machines are designed for high throughput, producing large quantities of filter cores in a fraction of the time required for manual production methods.

Furthermore, the cost-effectiveness of employing these machines extends beyond just labor savings. The precision engineering involved in the manufacture of spiral filter cores ensures that less material is wasted, contributing to lower raw material costs. Companies can achieve better profit margins while also producing high-quality products.

Environmental Impact

As industries become more environmentally conscious, the role of the spiral filter core making machine in promoting sustainability cannot be overlooked. With improved filtration efficiency, these cores help reduce water and air pollution by more effectively capturing harmful particles and contaminants. Additionally, the reduction in material waste during production aligns with eco-friendly manufacturing practices.

Conclusion

The spiral filter core making machine represents a significant advancement in filtration technology. By enhancing production efficiency, reducing costs, and improving product quality, this innovative equipment plays a pivotal role in meeting the growing demand for effective filtration solutions. As industries continue to prioritize sustainability and compliance with environmental standards, the spiral filter core and its manufacturing machine will undoubtedly remain integral to the future of filtration technology.

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025