Oct . 14, 2024 10:32 Back to list

Manufacturer of High-Performance Ultrafine Glass Fiber Filter Materials for Various Applications

Ultrafine Glass Fiber Filter Material An Overview of its Manufacturing and Applications

In the industrial sector, air and liquid filtration plays a critical role in maintaining environmental standards and promoting health safety. Among the various materials used for filtration, ultrafine glass fiber filter material has emerged as a leading choice due to its superior performance properties and versatility. This article aims to provide an overview of ultrafine glass fiber filter material, focusing on its manufacturing processes, advantages, and applications.

Manufacturing Process

The production of ultrafine glass fiber involves several sophisticated steps that ensure the final product meets the necessary performance criteria. The primary raw material is silica, which is melted at high temperatures to create glass. The molten glass is then extruded through fine nozzles, forming thin fibers. These fibers can be further processed through controlled solidification and cooling to achieve the desired diameter, typically in the range of 0.1 to 3 microns.

Once the fibers are generated, they are collected on a conveyor system, where they can be blended with specific additives to enhance their properties. These additives may include resin binders that provide structural integrity, ensuring that the fibers can withstand various operational conditions.

The next step involves the layering of these fibers to form a filter medium. Techniques like carding and air-laid methods are employed to achieve a uniform distribution of fibers, followed by compression and drying processes. The result is a robust filter material with an optimal thickness and high surface area, essential for trapping contaminants effectively.

Advantages of Ultrafine Glass Fiber Filter Material

Ultrafine glass fiber filter material boasts a myriad of advantages that set it apart from traditional filter media. Firstly, its high filtration efficiency is noteworthy; it can capture particulate matter, including fine dust, biological contaminants, and volatile organic compounds, with remarkable success. This characteristic is critical for applications demanding clean air quality, such as hospitals and laboratories.

ultrafine glass fiber filter material manufacturer

Furthermore, the temperature resistance of ultrafine glass fiber is substantially higher than that of synthetic fibers, allowing for its use in applications ranging from industrial processes to power generation. Its stability under extreme conditions ensures longevity and reliability, reducing the frequency of filter replacements.

Another significant benefit is its low pressure drop across the fiber medium. This means that less energy is required for air or liquid to pass through the filter, making ultrafine glass fiber an energy-efficient choice. As industries increasingly focus on sustainability, this feature is particularly appealing.

Applications

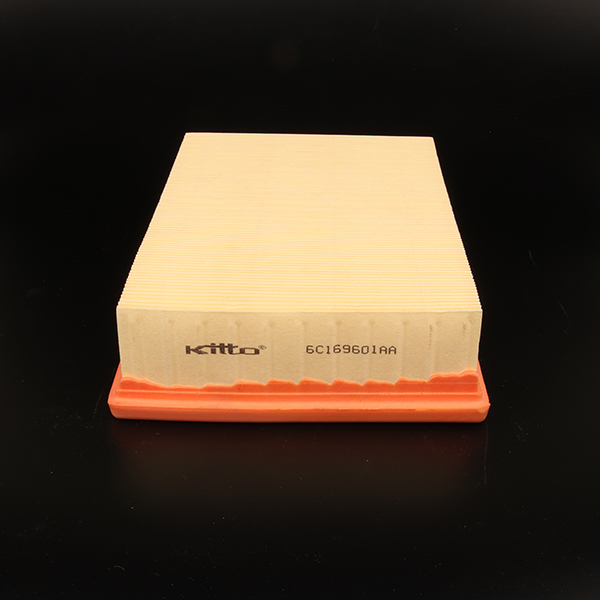

Ultrafine glass fiber filter materials find diverse applications across various sectors. In the automotive industry, they are used in cabin air filters, enhancing passenger comfort by removing pollutants and allergens from the air. Similarly, in HVAC systems, ultrafine glass fiber filters contribute to indoor air quality by capturing airborne particles.

The pharmaceutical industry relies on these filters to maintain sterile environments, crucial for the production of medications and medical devices. In manufacturing processes, they are employed in cleanroom applications, ensuring that products are not contaminated during production.

Moreover, their application extends to wastewater treatment processes, where ultrafine glass fiber filters help remove suspended solids and contaminants, ensuring compliance with environmental regulations.

Conclusion

The rise of ultrafine glass fiber filter materials as a preferred filtration medium can be attributed to their efficient performance, durability, and versatility across various industries. As the demand for cleaner air and water continues to grow globally, manufacturers of ultrafine glass fiber filters are poised to play a vital role in addressing environmental challenges and enhancing public health. With ongoing advancements in production techniques and material science, the future for ultrafine glass fiber filter materials looks promising, providing innovative solutions for filtration needs.

-

Premium OEM Snus Paper Supplier Custom Snus Filter & Packing Papers for Your Brand

NewsJul.05,2025

-

CE Certification PLJL-6 Six-Station Seal Leakage Tester for Spin-On Filter – High Efficiency & Reliability

NewsJul.05,2025

-

OEM PLXB-1 PU Pack Trimming Machine - Precision Cutting, High Efficiency, Reliable Quality

NewsJul.05,2025

-

Premium Engine Oil Filter Supplier & Exporter Reliable Engine Oil Filter Service

NewsJul.04,2025

-

Wholesale PLRZ-1000N Full-Auto Hot Melt Filter Paper Bonding Machine - High Efficiency & Precision

NewsJul.04,2025

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025