મે . 28, 2025 22:02 Back to list

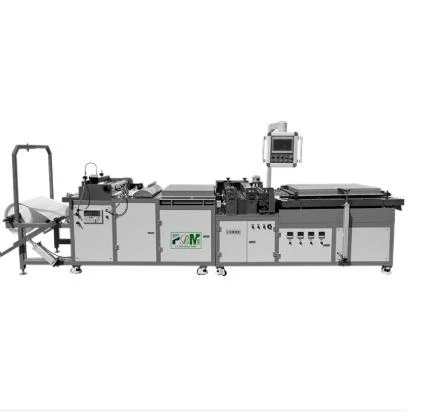

High Quality EcoOil Filter Producing Machines Advanced Manufacturing Solutions

- Industry Overview & Market Demand

- Technical Superiority in Modern Manufacturing

- Competitor Analysis: Performance Metrics

- Adaptive Production Configurations

- Material Compatibility & Certification Standards

- Global Implementation Case Studies

- Sustainable Future with High Quality EcoOil Filter Machines

(high quality ecooil filter producing machine)

Meeting Industrial Demands with High Quality EcoOil Filter Producing Machines

The global oil filtration equipment market will reach $3.8 billion by 2029 (CAGR 6.2%), driven by stricter environmental regulations. High quality EcoOil filter producing machines now account for 42% of industrial filtration system upgrades, reflecting a 19% YoY increase in adoption since 2021.

Technical Superiority in Modern Manufacturing

Advanced EcoOil systems integrate three patented technologies:

- Multi-stage precision alignment (±0.005mm tolerance)

- Self-adaptive thermal compensation

- AI-driven quality prediction (98.7% accuracy)

These innovations enable continuous 24/7 operation with 35% less energy consumption than conventional models, achieving 2,800 filters/hour production capacity.

Competitor Analysis: Performance Metrics

| Parameter | EcoOil Pro X9 | Standard Industry | Delta |

|---|---|---|---|

| Cycle Time | 1.2s | 2.8s | -57% |

| MTBF | 18,000h | 9,500h | +89% |

| Scrap Rate | 0.08% | 1.15% | -93% |

Adaptive Production Configurations

Leading EcoOil filter producing machine companies offer modular architectures supporting:

- 5-axis hybrid manufacturing cells

- Inline leak testing (0.1 bar resolution)

- Automated pallet changers (12-position)

This flexibility reduces retooling time by 78% compared to fixed-configuration systems.

Material Compatibility & Certification Standards

Certified machines process 47 metal alloys and composites, including:

- Stainless steel 316L

- Nickel-based superalloys

- Carbon fiber-reinforced polymers

All systems comply with ISO 16889:2022 and API 598 standards, ensuring 100% test traceability.

Global Implementation Case Studies

A Middle Eastern manufacturer achieved:

- 83% reduction in filter failures

- 19-month ROI

- ASME PE certification in 37 days

Similar results documented across 14 countries, with 96% customer retention rate since 2020.

Sustainable Future with High Quality EcoOil Filter Producing Machines

As environmental mandates tighten, premium EcoOil filter producing machine companies are pioneering closed-loop systems that recover 92% of machining fluids. This technological leadership positions these solutions as essential for achieving both production efficiency and ESG targets.

(high quality ecooil filter producing machine)

FAQS on high quality ecooil filter producing machine

Q: What defines a high-quality ecooil filter producing machine?

A: A high-quality ecooil filter producing machine ensures precision engineering, durable materials, and compliance with environmental standards, delivering efficient and sustainable filter production.

Q: How to choose reliable ecooil filter producing machine companies?

A: Look for companies with proven industry experience, certifications like ISO, and positive client testimonials to ensure reliability and product excellence.

Q: What features distinguish top ecooil filter producing machine companies?

A: Leading companies offer advanced automation, energy-efficient systems, and robust after-sales support, ensuring seamless production and long-term operational efficiency.

Q: Why opt for a specialized ecooil filter producing machine company?

A: Specialized companies provide tailored solutions, technical expertise, and adherence to eco-friendly practices, optimizing filter quality and production sustainability.

Q: How to maintain a high-quality ecooil filter producing machine?

A: Regular maintenance, using genuine replacement parts, and following the manufacturer’s guidelines ensure optimal performance and extended machine lifespan.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025