दिसम्बर . 25, 2024 16:28 Back to list

Semi-Automatic Cabin Air Filter Glue Application Machine for Efficient Production

The Role and Functionality of the PLLG-2 Semi-Auto Cabin Air Filter Gluing Machine

In today's fast-paced manufacturing landscape, efficiency and precision are paramount, especially in industries such as automotive and aerospace. One piece of machinery that has gained significant attention for its productivity and accuracy is the PLLG-2 semi-auto cabin air filter gluing machine. This innovative piece of equipment not only enhances operational efficiency but also ensures the high quality of cabin air filters, which are crucial for passenger safety and comfort.

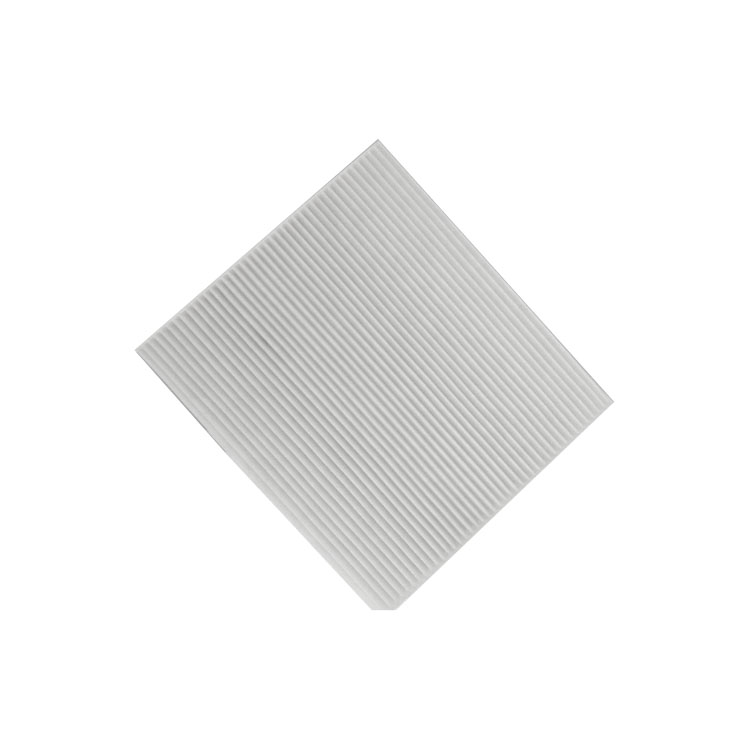

Understanding Cabin Air Filters

Cabin air filters are essential components in vehicles and aircraft, responsible for filtering out pollutants, allergens, and particulate matter from the air entering the cabin. Clean air is vital for the health and comfort of passengers, which is why manufacturing high-quality cabin air filters is essential. The gluing process, where the various layers of the filter are bonded together, plays a critical role in ensuring the longevity and effectiveness of these filters.

The Importance of Precision in the Gluing Process

The gluing process in cabin air filter production requires precision and consistency. Any imperfections in the gluing can compromise the structural integrity of the filter, leading to decreased performance and shorter lifespan. The PLLG-2 semi-auto cabin air filter gluing machine is designed to address these challenges by automating and standardizing the gluing process while allowing for manual intervention when necessary.

Key Features of the PLLG-2

One of the standout features of the PLLG-2 machine is its semi-automatic functionality. This means that while the machine handles the heavy lifting and precision tasks, operators can monitor and manage the process closely. The machine is equipped with advanced control systems that ensure the glue is applied evenly and in the right quantity, minimizing waste and enhancing product quality.

Moreover, the PLLG-2 is designed with user-friendly controls that make it accessible for operators with varying levels of experience. This reduces the training time required for new employees and allows for a more flexible workforce.

Efficiency and Cost-Effectiveness

pllg-2 semi-auto cabin air filter gluing machine products

In the manufacturing industry, time is often equated with money. The PLLG-2 machine significantly improves production rates by streamlining the gluing process. With its ability to consistently deliver high-quality gluing, manufacturers can reduce the rate of defective products that require rework or replacement. This not only saves time but also cuts down on material costs, making the entire operation more cost-effective.

Additionally, the semi-automatic nature of the machine means that manufacturers can scale their operations without the need for extensive investment in fully automated systems. This flexibility is particularly appealing for small to medium-sized manufacturers looking to expand their production capabilities.

Quality Control and Reliability

Quality control is vital in any manufacturing process, and the PLLG-2 machine plays a pivotal role in this regard. The precise application of adhesive helps to ensure that each air filter meets stringent quality standards. Furthermore, the machine is designed to be robust and reliable, reducing the likelihood of breakdowns and maintenance issues.

Regular maintenance is simplified, allowing manufacturers to keep the PLLG-2 in optimal working condition without significant downtime. The machine’s design incorporates easy access to key components, making it user-friendly for maintenance staff.

Environmental Considerations

As industries move towards more sustainable practices, the PLLG-2 semi-auto cabin air filter gluing machine aligns with these goals. By optimizing the glue application process, the machine minimizes waste and can utilize eco-friendly adhesives, contributing to a greener manufacturing process.

This attention to sustainability is increasingly important to consumers and regulatory bodies alike, making the PLLG-2 not just an investment in efficiency, but also in responsible manufacturing practices.

Conclusion

The PLLG-2 semi-auto cabin air filter gluing machine is a key player in modern manufacturing, particularly in sectors where air quality is paramount. By combining efficiency, precision, and cost-effectiveness, it provides manufacturers with the tools necessary to produce high-quality cabin air filters. As the demand for clean air in vehicles and aircraft continues to grow, investing in advanced machinery like the PLLG-2 will be crucial for staying competitive and ensuring passenger safety and comfort. Whether for new startups or established manufacturers, this gluing machine stands out as a vital asset in the production line.

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025

-

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

NewsAug.18,2025