Nov . 19, 2024 03:48 Back to list

oem filter papers

Understanding OEM Filter Papers The Key to Quality Filtration

In an era where precision and efficiency in laboratory and industrial processes are paramount, the importance of quality filtration cannot be overstated. At the heart of effective filtration systems lies OEM filter papers, a vital component that ensures contaminants are removed while retaining the desired substances. This article delves into what OEM filter papers are, their applications, and why they are crucial in various industries.

What are OEM Filter Papers?

OEM stands for Original Equipment Manufacturer, and in the context of filter papers, it refers to specialized papers designed specifically for particular equipment or applications. These filter papers are engineered to meet the stringent standards required by manufacturers and end-users, ensuring optimal performance and reliability. Unlike generic filter papers, OEM filter papers are tailored to enhance compatibility with specific filtration systems, thereby improving filtration efficiency and accuracy.

The Manufacturing Process

OEM filter papers are produced using high-quality cellulose fibers and other materials to achieve defined particle retention, flow rate, and strength characteristics. The manufacturing process involves several intricate steps, including the selection of raw materials, precise engineering of the paper’s thickness and density, and rigorous testing to ensure each batch meets the set specifications. This attention to detail ensures that OEM filter papers deliver consistent results, critical for laboratories and industries where the integrity of results is vital.

Applications of OEM Filter Papers

The versatility of OEM filter papers allows them to be employed in numerous sectors, including

1. Laboratory Filtration In research and development settings, OEM filter papers are used to separate solids from liquids in chemical and biological applications. Their precision ensures that the filtration process does not compromise the integrity of samples.

2. Pharmaceutical Industry The pharmaceutical sector relies heavily on OEM filter papers for the purification of raw materials and for ensuring the accuracy of drug formulations. The stringent regulatory requirements necessitate the use of filter papers that meet high-performance standards, making OEM options highly sought after.

3. Environmental Testing OEM filter papers are integral in environmental laboratories where they help in testing water and soil samples for contaminants. The well-defined porosity and retention capability of these papers ensure accurate analysis and compliance with environmental regulations.

oem filter papers

4. Food and Beverage Industry In food processing and quality control, OEM filter papers are used to ensure that products meet safety and quality standards. For instance, they play a key role in the filtration of oils, juices, and beverages, helping to remove impurities that could affect flavor and safety.

5. Industrial Applications Various manufacturing processes rely on OEM filter papers for effective filtration of liquids and gases. This includes applications in chemical processing, automotive, and electronics manufacturing, where precision and quality control are critical.

Benefits of Using OEM Filter Papers

The adoption of OEM filter papers offers several advantages

- Customization OEM filter papers are designed for specific applications, ensuring superior compatibility and performance. This customization minimizes the risk of mishaps caused by using inappropriate filter media.

- Consistency and Reliability Because these papers are rigorously tested and manufactured to meet exacting standards, they provide consistent and reliable results, which is essential in fields where accuracy is paramount.

- Quality Assurance Using OEM filter papers helps organizations maintain quality assurance processes. They provide the assurance that the filtration media used meet the manufacturer’s specifications, thus protecting the integrity of operations.

- Cost-Effectiveness While they may come at a premium compared to generic options, the long-term benefits of using OEM filter papers—such as reduced downtime from filtration issues—can outweigh the initial costs.

Conclusion

In summary, OEM filter papers are an essential component of many filtration processes across diverse industries. Their tailored design, high-quality manufacturing standards, and versatility ensure that they can meet the specific filtration needs of various applications. As industries continue to prioritize precision and reliability, the role of OEM filter papers will only become more significant, making them a crucial tool for professionals committed to maintaining the highest standards of quality in their work.

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025

-

CE Certification Auto/Truck Filter Paper Supplier – Premium Filtration Solutions for Vehicles

NewsJul.06,2025

-

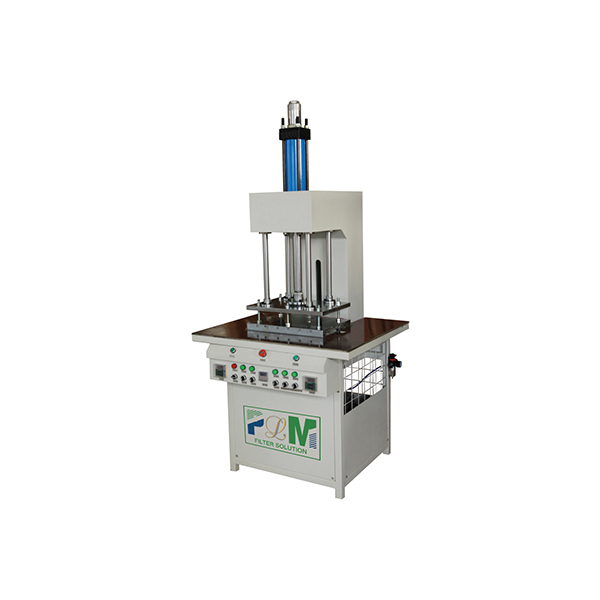

OEM PLGY-500 HDAF Mesh-Ends Hooking and Pressing Machine - High Efficiency, Precision, Reliable Performance

NewsJul.06,2025