pro . 12, 2024 09:21 Back to list

plmf-1 automatic production line for assembly sealing ring companies

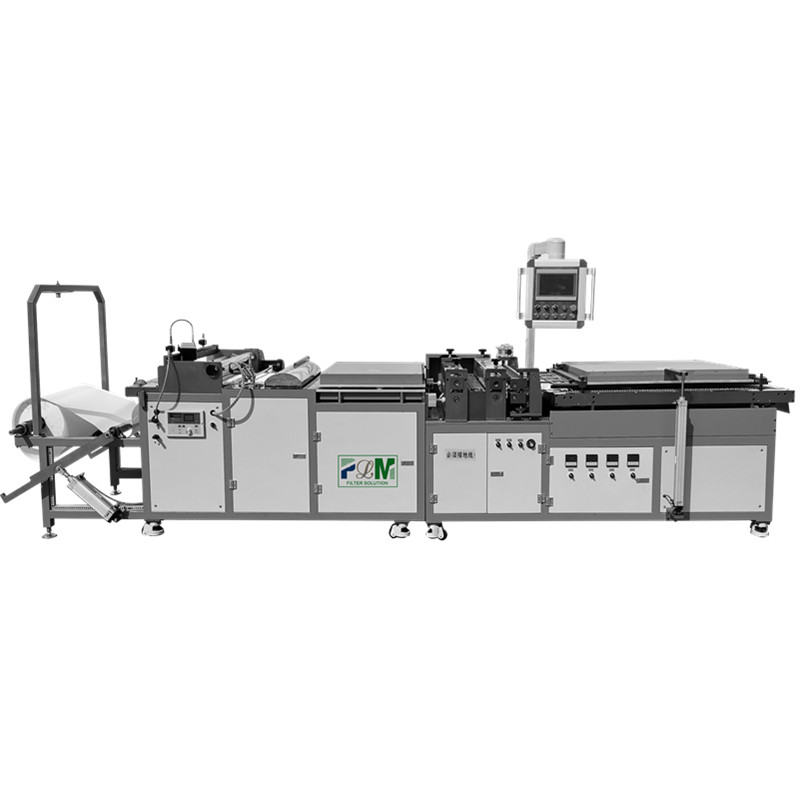

The PLMF-1% Automatic Production Line for Assembly Sealing Ring Companies

In today’s rapidly evolving manufacturing landscape, the demand for efficiency and precision continues to rise. Companies that specialize in the production of sealing rings face unique challenges, such as maintaining high quality while optimizing production processes. The PLMF-1% automatic production line emerges as a revolutionary solution for these businesses, integrating advanced technology to streamline operations and enhance productivity.

Understanding the Importance of Sealing Rings

Sealing rings are crucial components used in various industries, including automotive, aerospace, and machinery. They are designed to prevent leakage of fluids or gases, ensuring the efficient operation of engines, pumps, and other equipment. Given their critical role, the quality of sealing rings must be exceptionally high, and any defect can lead to serious operational failures. This underscores the importance of a robust manufacturing process capable of meeting stringent quality standards.

The PLMF-1% Automatic Production Line

The PLMF-1% automatic production line is engineered to address the specific needs of sealing ring manufacturers. It utilizes cutting-edge automation technology, allowing for high-speed production while maintaining superior quality control. One of the standout features of this production line is its integration of smart sensors and AI-driven analytics, which monitor the production process in real-time. This capability enables manufacturers to detect potential issues before they escalate, ensuring that every sealing ring produced meets the exact specifications required.

Key Features and Benefits

1. High Throughput The PLMF-1% line is designed for high-volume production. It automates several key processes, such as molding, curing, and quality inspection, which can significantly reduce production times and increase output.

plmf-1 automatic production line for assembly sealing ring companies

2. Precision Engineering With advanced robotics and precision machinery, the production line ensures that every sealing ring is manufactured within tight tolerances. This level of precision minimizes waste and rework, resulting in cost savings for manufacturers.

3. Quality Control The integration of smart sensors allows for continuous monitoring of the production process. This real-time data collection enables immediate adjustments to be made, ensuring consistent quality throughout the production cycle.

4. Flexibility The PLMF-1% line is adaptable to various sealing ring designs and materials. This flexibility is essential in a market that demands not only precision but also customization to meet specific client needs.

5. Energy Efficiency Utilizing modern technology, the production line is designed to be energy-efficient. This helps companies reduce their carbon footprint while also lowering operational costs.

Implementation and Support

The introduction of the PLMF-1% automatic production line is not just about technology; it also involves comprehensive support and training for staff. Manufacturers receive detailed training on operating and maintaining the equipment, which is crucial for maximizing its potential. Additionally, ongoing technical support ensures that companies can resolve any issues quickly, minimizing downtime and disruption to production.

Conclusion

The PLMF-1% automatic production line represents a significant advancement for companies involved in the production of sealing rings. By combining automation, precision engineering, and intelligent monitoring systems, this production line not only enhances productivity but also ensures that the highest quality standards are met. As industries continue to demand greater efficiency and reliability, the adoption of such innovative technologies will be essential for manufacturers striving to remain competitive in the global market. Embracing the PLMF-1% production line could very well pave the way for the future of sealing ring production, driving success and growth for companies ready to innovate.

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025