Nov . 24, 2024 11:56 Back to list

air filter air filter making machine suppliers

The Rising Demand for Air Filter Making Machines

As the world grapples with increasing air pollution and a growing awareness of health issues related to poor air quality, the demand for air filters has surged. Air filters are critical components in various settings, including homes, offices, industrial sites, and automobiles, ensuring that the air we breathe is clean and safe. Consequently, the market for air filter making machines is expanding, with numerous suppliers stepping up to meet this burgeoning demand.

Understanding Air Filters

Air filters serve the primary function of trapping airborne particles, allergens, pollutants, and pathogens. They come in various types, such as HEPA (High-Efficiency Particulate Air) filters, activated carbon filters, and electrostatic filters, each designed to address specific air quality challenges. The effectiveness of these filters significantly depends on the quality of materials used and the precision of their manufacturing processes. This is where air filter making machines come into play.

The Role of Air Filter Making Machines

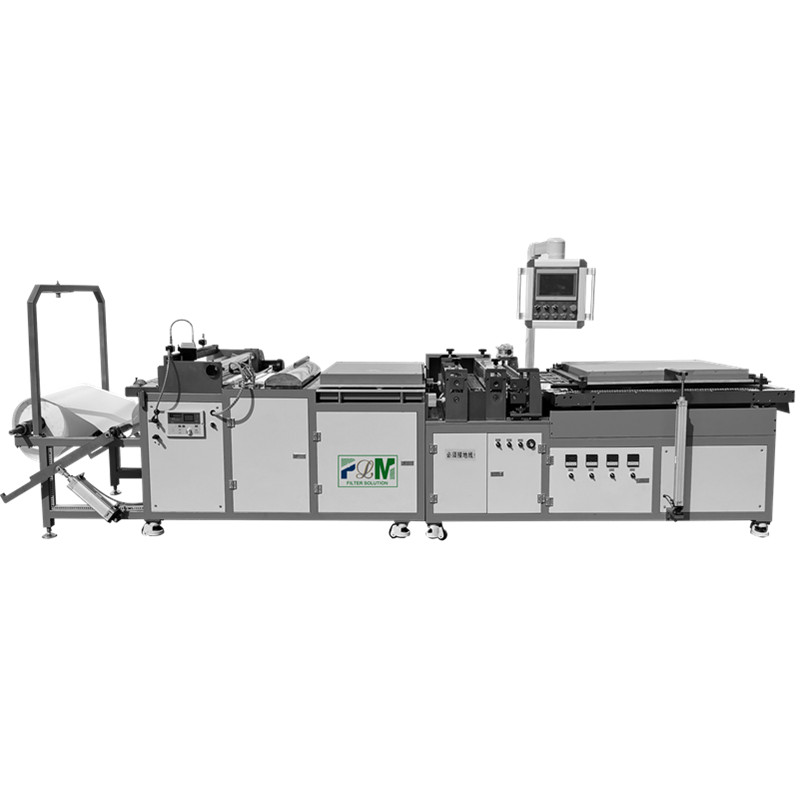

Air filter making machines are specialized equipment designed for the production of air filters. These machines automate the manufacturing process, ensuring consistency, efficiency, and high quality. Some common types of machines include

1. Automatic Filter Pleating Machines These machines create pleats in filter media to increase surface area, enhancing filtration efficiency. 2. Cutting and Die-Cutting Machines These devices cut filter materials into specific shapes and sizes required for different applications. 3. Ultrasonic Welding Machines Used for sealing filter elements, ensuring that no pollutants can bypass the filter. 4. Packaging Machines After production, air filters need to be packaged securely for distribution. These machines automate that process.

The manufacturing process involves several stages, including material preparation, pleating, cutting, assembly, and packaging. Each of these stages requires specialized machines to ensure that the end product meets stringent quality standards.

air filter air filter making machine suppliers

Key Suppliers of Air Filter Making Machines

With the increasing demand for air filtration solutions, numerous suppliers have emerged in the market, focusing on providing high-quality air filter making machines. These suppliers offer a variety of equipment tailored to different production needs. Key suppliers include

1. A.C. Machines Known for their advanced automation technology, A.C. Machines offers a range of pleating and cutting machines that enhance production speed and efficiency. 2. AirTech Systems Specializing in custom solutions, AirTech designs machines suited for high-capacity production lines, making them a preferred choice for large manufacturers. 3. FilterTech With a focus on eco-friendly manufacturing processes, FilterTech provides machines that minimize waste and energy consumption, aligning with the sustainable practices many companies are adopting. 4. Global Filtration Equipment This supplier boasts a global network, offering reliable machines along with comprehensive after-sales support, making them a favored choice for international buyers.

Why Choose the Right Supplier?

Selecting the right supplier of air filter making machines is crucial for several reasons

- Quality Assurance High-quality machines lead to better product results, ensuring that the air filters produced meet industry standards. - Customization Options The ability to customize machines according to specific production requirements can enhance operational efficiency. - Technical Support A reliable supplier provides necessary technical support and training, which is essential for maintaining machine performance and longevity. - Cost-Effectiveness Investing in quality machinery from a reputable supplier can lead to lower operational costs in the long run due to reduced downtime and maintenance needs.

Conclusion

The growing concerns over air quality and health have precipitated a significant uptick in the demand for air filters and their manufacturing processes. With the vital role that air filter making machines play in this industry, suppliers are stepping up to provide innovative and efficient solutions. For manufacturers, partnering with the right supplier can lead to improved product quality, operational efficiency, and ultimately, a healthier environment for all. As the market continues to evolve, staying informed about advancements in air filter technology and manufacturing processes will be key for businesses looking to thrive in this essential sector.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025