Nov . 08, 2024 23:46 Back to list

Innovative Paper Folding Device for Enhancing Air Filter Manufacturing Efficiency

The Importance of Paper Folding Machines for Air Filter Suppliers

In the ever-evolving world of manufacturing, efficiency and precision are paramount, especially in industries as critical as air filtration. As consumers and businesses alike become more aware of air quality issues, the demand for high-performance air filters is on the rise. To meet this demand, air filter suppliers must optimize their manufacturing processes. One of the significant advancements that have emerged in this field is the use of paper folding machines. This technology not only enhances productivity but also ensures consistency in product quality.

Understanding Paper Folding Machines

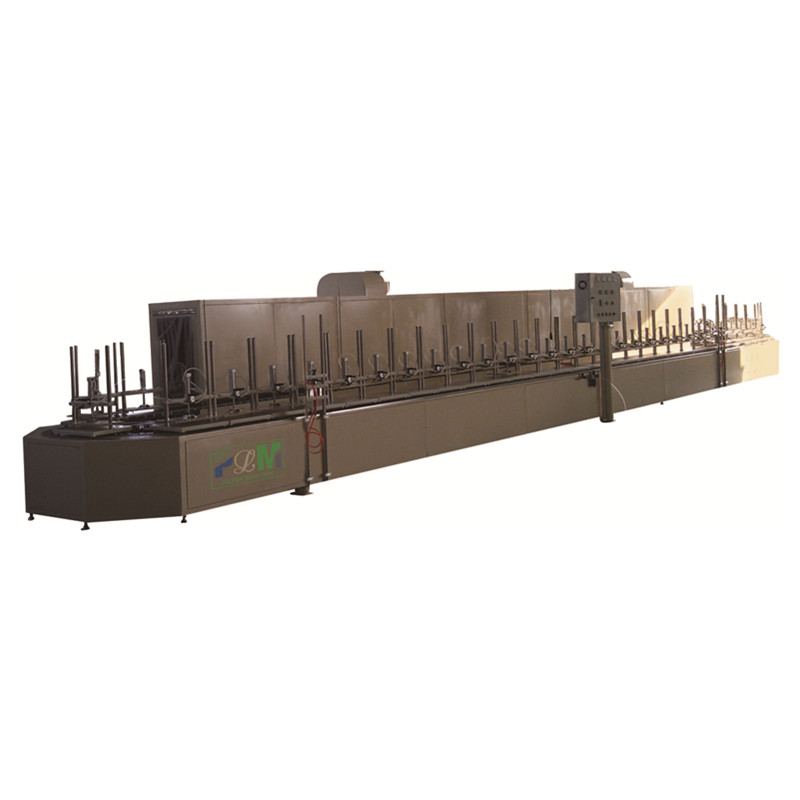

Paper folding machines are specialized equipment designed to fold various types of paper, including those used in the production of air filters. These machines can handle different sizes and types of paper, making them versatile tools for manufacturers. The automated nature of these machines significantly reduces manual labor, allowing for faster production times while minimizing the risk of human error.

The technology behind paper folding machines involves sophisticated mechanics and robotics. Typically, these machines feature multiple folding stations, enabling them to execute different fold styles and patterns. This is particularly important for air filter production, as the configuration of the filter media often dictates its performance. A well-folded filter allows for better airflow and improved filtration efficiency.

Enhancing Production Efficiency

For air filter suppliers, time is money. The integration of paper folding machines into the manufacturing process can drastically improve production efficiency. Automated folding translates to a higher output rate; machines can operate continuously with minimal downtime, resulting in increased throughput. This is crucial for suppliers facing high demand and tight deadlines, especially during seasonal peaks when air quality concerns are heightened.

Moreover, these machines can significantly reduce waste. Manual folding processes often lead to misaligned folds or inconsistent sizes, resulting in material waste. Paper folding machines, with their precision engineering, ensure consistent folds and dimensions, optimizing material usage. This not only contributes to cost savings but also aligns with sustainability goals by reducing waste.

paper folding machine for air filter suppliers

Quality Control and Consistency

Quality is a non-negotiable factor in air filter production. The effectiveness of an air filter hinges on its ability to capture particulate matter and facilitate airflow without restriction. Inconsistent folding can lead to gaps or uneven surfaces in the filter structure, compromising performance.

Paper folding machines are equipped with advanced sensors and control systems that monitor the folding process in real-time. These systems can detect anomalies and make automatic adjustments to ensure that every fold meets specified parameters. By standardizing the folding process, manufacturers can guarantee that each filter performs to its highest potential, resulting in enhanced customer satisfaction and trust in the brand.

Cost-Effectiveness and ROI

While the initial investment in paper folding machines may seem substantial, the long-term benefits far outweigh the costs. The automation of folding processes can reduce labor costs significantly, allowing staff to focus on higher-value tasks such as quality inspection and process optimization. Additionally, the increased efficiency and reduced waste translate to lower operational costs over time.

Air filter suppliers considering the transition to automated folding machinery will likely see a rapid return on investment (ROI). With the growing emphasis on air quality in both commercial and residential settings, the need for reliable, high-quality air filters is only set to increase. Suppliers who invest in technology that enhances their production capacity and product quality will be well-positioned to capture greater market share.

Conclusion

In conclusion, the implementation of paper folding machines is a game-changer for air filter suppliers. By enhancing production efficiency, ensuring quality consistency, and creating cost-effective manufacturing processes, these machines can significantly contribute to the success of air filter manufacturing. As the industry continues to evolve in response to environmental concerns and consumer demand, the adoption of advanced technologies such as paper folding machines will likely become a standard practice, ensuring that suppliers meet the challenges of tomorrow while delivering high-quality products today.

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025