Nov . 27, 2024 19:12 Back to list

PLC-B500 Automated Cabin Air Filter Adhesive Application System

Understanding the PLCB-500 Full-Auto Cabin Air Filter Gluing Machine

In the automotive industry, the quality of cabin air filters plays a critical role in maintaining a healthy environment inside vehicles. As manufacturers strive to enhance the efficiency of the production process while ensuring high-quality outputs, advanced machinery like the PLCB-500 Full-Auto Cabin Air Filter Gluing Machine has become essential. This article explores the features, advantages, and potential impact of this innovative machine on production lines.

Features of the PLCB-500

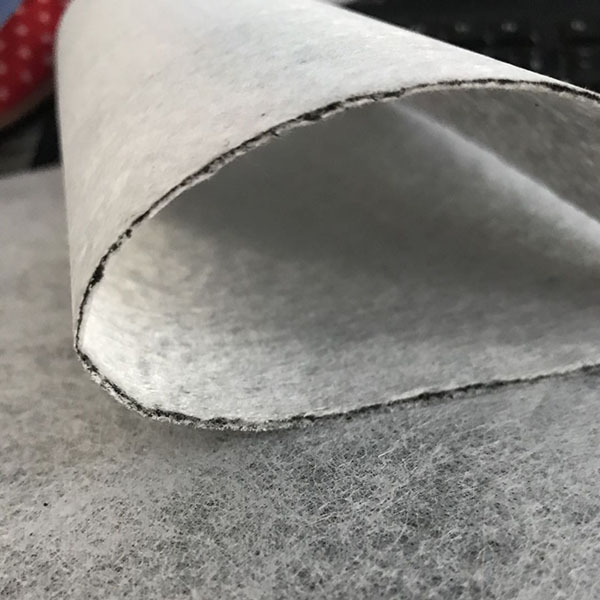

The PLCB-500 is a state-of-the-art, fully automatic machine designed specifically for gluing cabin air filters. One of its standout features is its high-speed operation, which dramatically increases productivity. The machine is capable of handling multiple production phases, including gluing, cutting, and assembly, all in one seamless workflow. This integration not only saves time but also reduces labor costs significantly as fewer operators are needed to complete the same volume of work.

Equipped with advanced programmable logic controllers (PLC), the PLCB-500 allows for precise control over the gluing process. Operators can customize settings based on the specifications of different filter models, ensuring that the adhesive is applied uniformly and effectively. Additionally, this adjustability mitigates the risk of errors, leading to a consistent quality of the final products.

Another notable feature of the PLCB-500 is its user-friendly interface, which streamlines the operational process. The digital display provides real-time feedback, allowing operators to monitor performance and make adjustments as needed. This level of interactivity helps in troubleshooting and ensures that production runs smoothly without unexpected downtime.

Advantages of the PLCB-500

1. Increased Production Efficiency The automation provided by the PLCB-500 allows manufacturers to significantly increase their output. By reducing the manual labor involved in assembling cabin air filters, companies can meet higher demand without compromising quality.

plcb-500 full-auto cabin air filter gluing mchine quotes

2. Consistency and Quality Control With the machine’s ability to apply glue uniformly, manufacturers can create filters that meet stricter quality standards. This consistency is essential in industries like automotive, where product reliability is crucial for customer satisfaction and safety.

3. Cost Reduction Although the initial investment in the PLCB-500 may be substantial, the long-term savings are notable. By lowering labor costs and minimizing material waste through precise glue application, businesses can achieve a higher return on investment.

4. Sustainability The efficiency of the PLCB-500 also contributes to more sustainable manufacturing practices. With less leftover adhesive and reduced energy consumption during production, companies are better positioned to meet environmental standards and reduce their ecological footprint.

5. Versatility The PLCB-500 can be adapted to work with various filter designs and adhesive types, making it an excellent addition for manufacturers looking to diversify their product offerings. This versatility ensures that companies can stay ahead of market trends.

Conclusion

The PLCB-500 Full-Auto Cabin Air Filter Gluing Machine represents a significant advancement in the manufacturing of automotive components. By integrating automation, precision control, and user-friendly design, this machine addresses key challenges faced by manufacturers in the competitive automotive market. The benefits of increased production efficiency, consistent quality, cost savings, and improved sustainability make it an attractive option for businesses aiming to enhance their operational capabilities.

As the automotive industry continues to evolve, investing in modern solutions like the PLCB-500 can provide companies with the leverage they need to succeed in a fast-paced environment. By adopting such technology, manufacturers not only improve their own processes but also contribute to the overall advancement of the industry, setting new benchmarks for quality and efficiency. In an age where customer satisfaction is paramount, the PLCB-500 is more than just a machine; it is a vital tool for securing a competitive edge.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025