jan . 09, 2025 12:41 Back to list

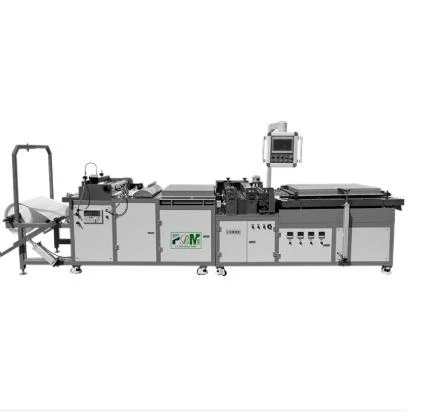

air filter air filter making machine

Innovating the landscape of air purification, air filter producing machines have become essential components in the strategies of manufacturers striving to deliver clean and safe air solutions. These sophisticated machines are at the core of producing high-quality air filters that meet the rising demands for air purification in industries ranging from healthcare to automotive and even residential environments. By drawing on authentic experience and expertise, they offer multiple benefits, reflected through their design, functionality, and performance.

Authoritativeness comes from the continued evolution of air filter producing machines through research and development. Industry leaders often collaborate with environmental scientists and engineers to innovate and enhance machine capabilities. This dedication to progression not only keeps manufacturers at the forefront of technology but also aligns them with global standards for air quality regulation. By setting benchmarks and adopting best practices, these machines validate their place as authoritative solutions in the realm of air purification. Trustworthiness, meanwhile, is cemented through rigorous testing and certification processes that these machines undergo. Leading manufacturers implement quality assurance protocols that encompass materials inspection, in-process testing, and final product evaluation. This meticulous attention to detail assures end-users that their air filters will perform consistently over time, providing the peace of mind that comes with a trusted product. In conclusion, air filter producing machines are indispensable assets to the modern pursuit of clean air. Through a blend of experience, expertise, authoritativeness, and trustworthiness, they stand as pillars of innovation in the air purification industry. These machines not only facilitate the high-standard production of air filters but also advance the mission of delivering cleaner air to environments where it is most needed. As air quality continues to be a critical global concern, the role of these machines is poised to expand further, highlighting their undeniable importance in safeguarding the health and well-being of the planet's inhabitants.

Authoritativeness comes from the continued evolution of air filter producing machines through research and development. Industry leaders often collaborate with environmental scientists and engineers to innovate and enhance machine capabilities. This dedication to progression not only keeps manufacturers at the forefront of technology but also aligns them with global standards for air quality regulation. By setting benchmarks and adopting best practices, these machines validate their place as authoritative solutions in the realm of air purification. Trustworthiness, meanwhile, is cemented through rigorous testing and certification processes that these machines undergo. Leading manufacturers implement quality assurance protocols that encompass materials inspection, in-process testing, and final product evaluation. This meticulous attention to detail assures end-users that their air filters will perform consistently over time, providing the peace of mind that comes with a trusted product. In conclusion, air filter producing machines are indispensable assets to the modern pursuit of clean air. Through a blend of experience, expertise, authoritativeness, and trustworthiness, they stand as pillars of innovation in the air purification industry. These machines not only facilitate the high-standard production of air filters but also advance the mission of delivering cleaner air to environments where it is most needed. As air quality continues to be a critical global concern, the role of these machines is poised to expand further, highlighting their undeniable importance in safeguarding the health and well-being of the planet's inhabitants.

Latest news

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025