okt . 09, 2024 14:11 Back to list

PP sediment filter production equipment for efficient water purification solutions

The Importance of PP Sediment Filter Making Machines

In today’s modern world, ensuring clean and safe drinking water is a priority for both consumers and industries. One effective method of achieving this is through the use of polypropylene (PP) sediment filters. These filters are crucial in removing contaminants from water, making it safe for consumption and use in various applications. To meet the growing demand for such filters, the PP sediment filter making machine has emerged as a significant piece of equipment in the manufacturing process.

Understanding PP Sediment Filters

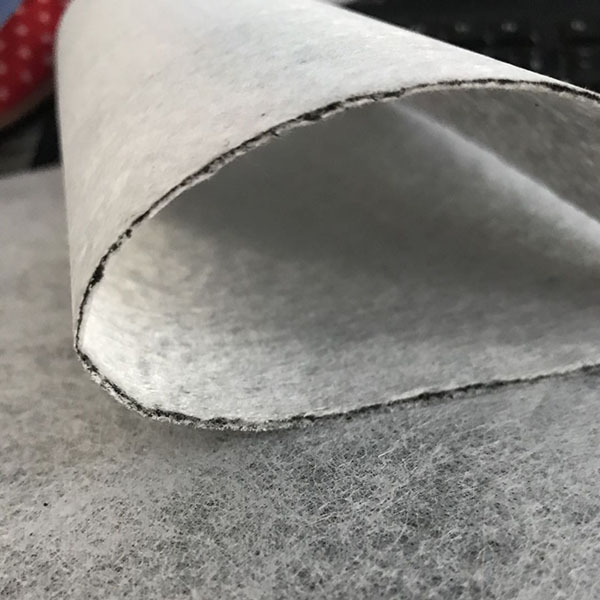

PP sediment filters are designed to trap and remove particulate contaminants from water. These include sand, silt, rust, and other impurities that can compromise water quality. Made from high-grade polypropylene, these filters are appreciated for their durability, chemical resistance, and effectiveness in various filtration applications. They are widely used in residential, commercial, and industrial water filtration systems.

The Role of PP Sediment Filter Making Machines

The production of PP sediment filters requires precision and efficiency, which is why the PP sediment filter making machine is critical. These machines are designed to automate the manufacturing process, ensuring consistent quality and high output. They utilize advanced technology to mold, shape, and assemble the filter elements, significantly reducing the time and labor needed compared to manual production methods.

One of the key features of these machines is their ability to produce filters of various specifications. This flexibility allows manufacturers to meet the diverse needs of different markets, from household filters to those suited for industrial applications. Additionally, modern machines are equipped with user-friendly controls and monitoring systems, making it easier to operate and maintain production quality.

Advantages of Automating the Manufacturing Process

pp sediment filter making machine

Investing in a PP sediment filter making machine offers several advantages

1. Increased Production Efficiency With automation, production rates significantly increase, allowing manufacturers to meet high demand and reduce lead times.

2. Consistent Quality Automated machines produce filters with uniform specifications, minimizing deviations that can occur in manual production.

3. Cost-Effectiveness Although the initial investment in machinery can be high, the long-term savings in labor costs and increased output can lead to a better return on investment.

4. Sustainability Many modern machines are designed to be energy-efficient and reduce waste, contributing to more sustainable manufacturing practices.

5. Adaptability Manufacturers can easily switch between different filter designs and sizes, providing greater flexibility in production to cater to market changes.

Conclusion

As the demand for clean water continues to rise, the role of PP sediment filter making machines in the production of effective filtration systems becomes increasingly important. These machines not only enhance the efficiency and quality of production but also support manufacturers in meeting the growing needs of both the consumer and industrial markets. By investing in advanced technology, manufacturers can ensure they remain competitive while contributing to global efforts towards clean water accessibility. In a world where water quality can no longer be taken for granted, the importance of these machines and the filters they produce cannot be overstated.

-

AI-Optimized Active Carbon Filter for Air Purifiers | 51 chars

NewsAug.02,2025

-

Premium Active Carbon Air Filter for Air Purifiers | Odor Removal

NewsAug.01,2025

-

Activated Carbon Air Filters: Ultimate Odor Removal for Purifiers

NewsJul.31,2025

-

PP Spun Filter Cartridge Making Machine for Efficient Filtration Solutions

NewsJul.29,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor & Pollutant Removal

NewsJul.29,2025

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.28,2025