dec . 11, 2024 10:33 Back to list

Service for Raw Materials in Primary Air Filter Production

Understanding Primary Air Filter Raw Material Service

In today's world, where industrialization and urbanization are at an all-time high, the quality of air we breathe has become a pressing concern. As such, the importance of primary air filters has increased significantly. These filters play a crucial role in purifying the air by trapping pollutants, dust particles, and other harmful substances. However, the efficacy of these filters largely depends on the raw materials used in their manufacturing. This article delves into the significance of primary air filter raw material services and their impact on air quality and industry standards.

The Role of Raw Materials in Air Filters

Raw materials are fundamental to the production of effective air filters. The types of materials used can greatly influence the performance, lifespan, and overall efficiency of the filters. Common raw materials for primary air filters include fiberglass, synthetic fibers, and natural fibers such as paper. Each of these materials offers distinct advantages and disadvantages. For instance, fiberglass filters are known for their durability and high dirt-holding capacity, while synthetic and natural fibers may offer better environmental sustainability.

In addition, the choice of raw materials directly affects the filtration mechanism. Some filters rely on mechanical filtration, which physically captures particles, whereas electrostatic filters use an electric charge to attract and trap pollutants. Understanding the properties of different raw materials can help manufacturers design filters that not only meet regulatory standards but also provide superior air quality.

Quality Control and Sourcing

With the rising demand for clean air solutions, the quality of raw materials has come under scrutiny. Manufacturers must ensure that they source materials from reliable suppliers who adhere to strict quality control measures. Poor-quality raw materials can lead to ineffective filters that may fail to capture harmful particles, ultimately jeopardizing air quality.

Sourcing raw materials involves evaluating various factors such as the material's performance characteristics, cost-effectiveness, and environmental impact. Manufacturers are increasingly adopting sustainable practices, looking towards recycled or biodegradable materials as viable options. This shift not only meets consumer demand for eco-friendly products but also helps reduce waste in the manufacturing process.

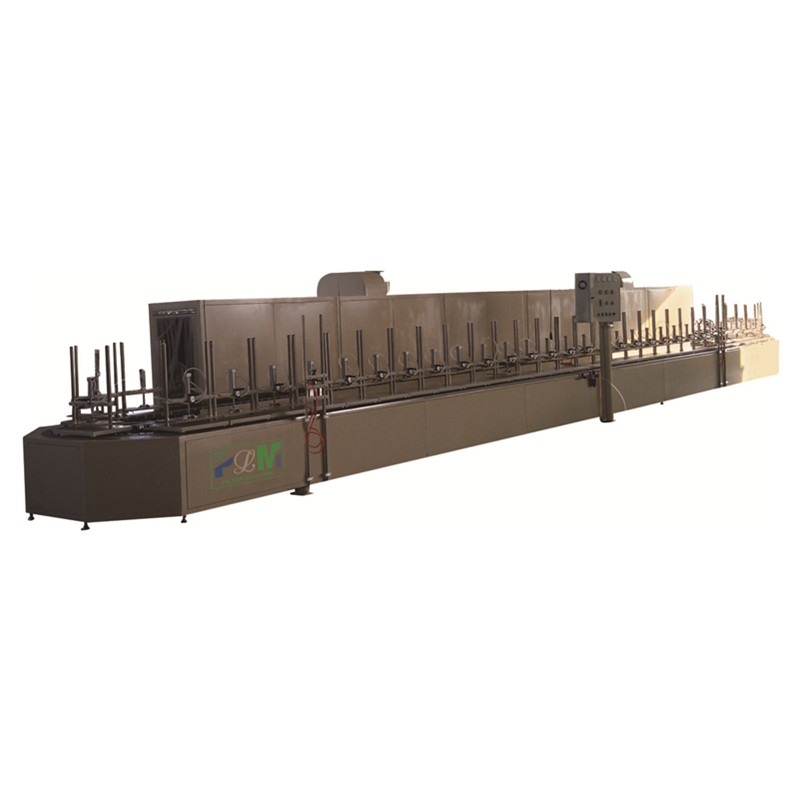

primary air filter raw material service

Cost Implications of Raw Material Choices

The selection of raw materials has significant cost implications for manufacturers. Premium materials tend to be more expensive, which can increase production costs. However, investing in high-quality materials often results in filters that last longer and perform better. In the long run, this can translate to lower replacement costs and improved customer satisfaction.

On the other hand, opting for cheaper raw materials may save money in the short term but can lead to increased operational costs due to frequent filter replacements and the potential need for more extensive maintenance protocols. Consequently, manufacturers must conduct a thorough cost-benefit analysis when choosing raw materials for primary air filters.

Innovations in Raw Materials

The air filtration industry is witnessing numerous innovations aimed at improving filter performance and sustainability. Advances in technology have led to the development of new synthetic materials that enhance filtration efficiency while minimizing environmental impact. Additionally, nanotechnology is being explored to create filters that can capture even smaller particles, including viruses.

Such innovations not only improve the effectiveness of air filters but also pave the way for smarter applications in various sectors. For example, energy-efficient filters can reduce the strain on HVAC systems, leading to lower energy consumption and operational costs.

Conclusion

In conclusion, the raw materials used in the production of primary air filters significantly influence their efficiency, durability, and overall performance. By prioritizing quality sourcing, manufacturers can ensure that their filters not only comply with industry standards but also contribute positively to public health. As the demand for cleaner air continues to rise, innovations in raw material technology will be paramount in meeting these needs while promoting environmental sustainability. Investing in high-quality raw materials is not just a cost, but a commitment to enhancing air quality for future generations. Therefore, paying attention to raw material services is vital for anyone engaged in the air filtration industry, as it ultimately shapes the effectiveness of our air quality management systems.

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025