Des . 23, 2024 05:44 Back to list

filter spiral tube machine service

The Importance of Filter Spiral Tube Machine Service

In the modern manufacturing and industrial sectors, the demand for efficient filtration systems has never been greater. As companies seek to improve product quality, ensure compliance with environmental regulations, and maintain operational efficiency, the focus on effective filtration solutions has become paramount. One of the pivotal components that facilitate high-quality filtration is the filter spiral tube machine. This machinery plays a crucial role in producing filter elements that serve various industries, including automotive, chemical, food and beverage, and pharmaceuticals. However, to maximize the effectiveness and longevity of these machines, proper servicing is essential.

Understanding the Filter Spiral Tube Machine

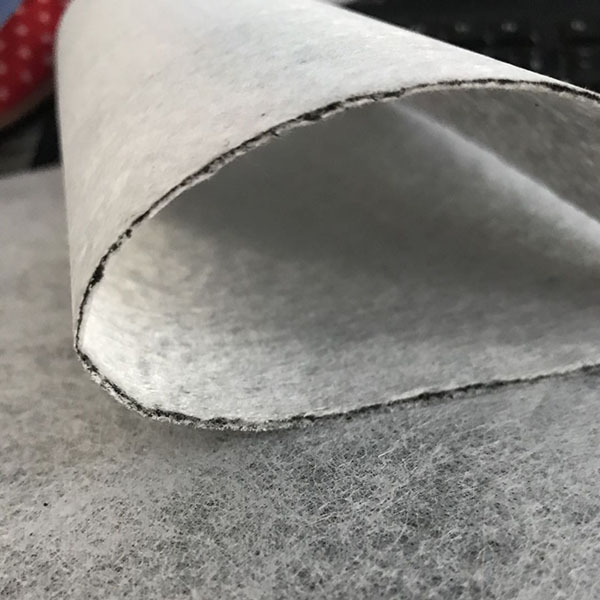

The filter spiral tube machine is designed to create spiral-wound filter tubes that are integral in the filtration process. These tubes are manufactured using a combination of high-quality materials and advanced engineering techniques. The design allows for increased surface area, enhancing the filter's ability to capture impurities and particles efficiently. Over time, the quality of the filter is directly linked to how well the machine operates. Thus, regular maintenance and servicing of this equipment are vital.

Why Regular Service is Critical

1. Operational Efficiency Like any machinery, the filter spiral tube machine is subject to wear and tear. Regular servicing helps identify potential issues before they escalate into significant problems that can halt production. Keeping the machine in optimal condition enhances its efficiency, leading to better overall productivity in the manufacturing process.

2. Quality Assurance The quality of the filter tubes produced is directly related to the performance of the machine. Regular maintenance ensures that all components are functioning correctly, which, in turn, guarantees the production of high-quality filter elements. Consistent quality helps companies meet their customers' expectations and maintain their reputations in the market.

3. Cost Reduction Investing in regular service can significantly reduce overall operational costs. By preemptively addressing minor issues, companies can avoid costly repairs or even the need to replace an entire machine. Furthermore, a well-maintained machine operates more efficiently, reducing energy consumption and decreasing waste.

4. Safety Compliance Many industries face stringent regulations regarding safety and environmental standards. Regular servicing ensures that the filter spiral tube machine complies with these standards, minimizing the risk of legal issues or fines. Maintaining proper operation also contributes to a safer working environment for employees.

filter spiral tube machine service

5. Extended Lifespan of Equipment Just like a vehicle that requires routine oil changes and checkups, machines also need regular servicing to extend their lifespan. With proper care, a filter spiral tube machine can operate effectively for many years, maximizing return on investment.

Key Service Components

When considering service for filter spiral tube machines, several key areas require attention

- Inspection Regular inspection of the machine’s mechanical and electrical components ensures that everything is in working order. This includes checking for wear and tear and ensuring all parts are calibrated correctly.

- Cleaning Dirt and debris can significantly affect machine performance. Regular cleaning of the machine helps maintain efficiency and reduces the likelihood of breakdowns.

- Lubrication Proper lubrication of moving parts is vital to prevent friction and overheating. Scheduled lubrication ensures all components function smoothly.

- Calibration Machines can drift out of alignment over time. Regular calibration helps maintain accuracy in production, which is crucial for maintaining product specifications.

Conclusion

In conclusion, the filter spiral tube machine is an essential asset in many industries, providing crucial filtering solutions. However, its effectiveness is heavily reliant on proper and regular servicing. By prioritizing maintenance, businesses can ensure operational efficiency, product quality, and compliance with safety regulations while also reducing costs and extending the lifespan of their equipment. Investing in comprehensive service for filter spiral tube machines not only supports the longevity of the machinery but also enhances the overall success of the manufacturing process. In today’s competitive market, the importance of such operational excellence cannot be overstated.

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025