Dec . 12, 2024 09:34 Back to list

filter element

Understanding Filter Elements A Critical Component in Filtration Systems

In various industries and applications, filter elements play a vital role in maintaining the integrity and efficiency of filtration systems. These components are designed to separate contaminants from fluids, ensuring that processes run smoothly and that products meet the necessary quality standards. As we delve into the world of filter elements, it is essential to understand their design, function, and significance in different contexts.

What is a Filter Element?

A filter element is the core component of a filtration system, responsible for removing undesirable particles, such as dirt, dust, and microbes, from liquids or gases. These elements can vary widely in their design, material, and size, depending on the specific application. Common materials used for filter elements include paper, fabric, ceramic, and various synthetic materials, each chosen for its ability to capture particular contaminants.

Types of Filter Elements

There are several types of filter elements, each tailored for specific functions and applications. The most common types include

1. Mechanical Filters These filters utilize a physical barrier to trap particles. They can be made from woven fabrics, foams, or membranes. Mechanical filters are widely used in air and water purification systems.

2. Activated Carbon Filters These elements use activated carbon to absorb contaminants. They are particularly effective at removing organic compounds and odors from liquids and gases, making them popular in water treatment and air purification applications.

3. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are designed to capture 99.97% of particles that are 0.3 microns and larger. They are essential in environments requiring high air quality, such as hospitals, laboratories, and cleanrooms.

filter element

5. Strainers Often used in plumbing and water systems, strainers are coarse filters that remove larger particles to protect downstream equipment from damage.

The Importance of Filter Elements

Filter elements are crucial for numerous reasons. First and foremost, they protect machinery and equipment from damage caused by contaminants. For example, in industrial settings, contaminated oil can lead to premature wear and tear of engines and hydraulic systems, resulting in costly repairs and downtime. High-quality filter elements can significantly extend the lifespan of such systems.

Moreover, filter elements are essential for maintaining product quality. In industries such as food and beverage, pharmaceuticals, and electronics, even the smallest contaminants can compromise the safety and effectiveness of the final product. For instance, in semiconductor manufacturing, even minute levels of particulates can result in defects in microchips. Thus, filter elements contribute to the overall efficiency and reliability of production processes.

Maintenance and Replacement

To ensure optimal performance, regular maintenance and timely replacement of filter elements are necessary. Over time, filters can become clogged with captured particles, reducing their effectiveness and potentially leading to system failures. The frequency of replacement depends on several factors, including the type of filter, the application, and the level of contaminants present. Facility managers must monitor filter performance and implement a proactive maintenance schedule to avoid unexpected disruptions.

Conclusion

In summary, filter elements are integral components of filtration systems across various industries. Their ability to remove contaminants not only protects equipment and enhances lifespan but also ensures that products meet quality standards essential for consumer safety and satisfaction. With a variety of filter types available, it is crucial for businesses to select the appropriate filter elements for their specific needs and maintain them regularly to achieve optimal performance. As technology continues to evolve, we can expect further innovations in filter design and materials, improving efficiency and effectiveness in filtration processes. Addressing these elements is not just a matter of compliance; it is a smart investment in operational excellence.

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

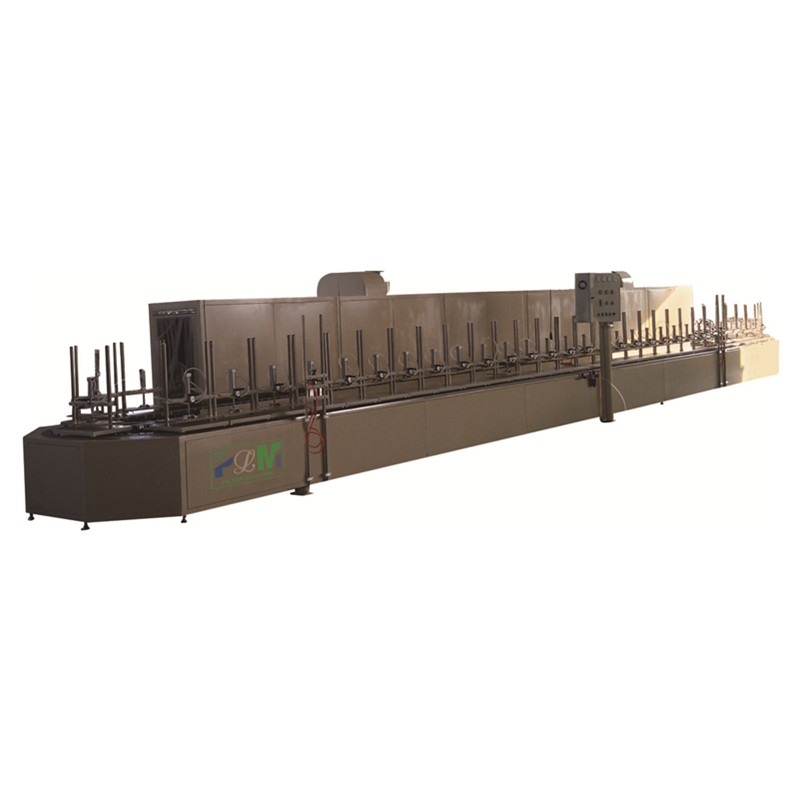

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025