Dic . 04, 2024 10:02 Back to list

Manufacturers of Roll-Formed Carbon Air Filters for Enhanced Air Purification Solutions

The Role of Carbon Air Filters in Roll Manufacturing

In the contemporary landscape of manufacturing, the focus on sustainability and environmental responsibility has become increasingly paramount. Among the various innovations that contribute to cleaner production processes, carbon air filters stand out as essential tools, particularly in roll manufacturing. These filters play a crucial role in mitigating air pollution, ensuring product quality, and promoting the health of workers and the surrounding community.

Understanding Carbon Air Filters

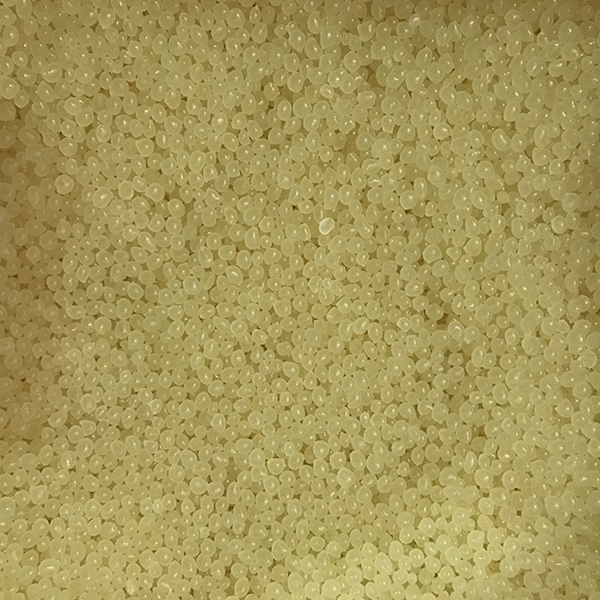

Carbon air filters are designed to absorb and neutralize volatile organic compounds (VOCs), odors, and other airborne pollutants. They utilize activated carbon, a highly porous material that can capture and retain impurities from the air. This technology is particularly beneficial in roll manufacturing, where processes may release dust, fumes, and volatile chemicals. By implementing carbon air filters, manufacturers can significantly reduce the emission of harmful substances into the atmosphere.

Benefits in the Roll Manufacturing Process

1. Improved Air Quality The manufacturing of rolls—whether it be paper, plastic, or textiles—often involves the use of chemicals and materials that emit harmful VOCs. Carbon air filters effectively capture these emissions, ensuring that the air quality within the manufacturing facility remains safe for workers. This improvement in air quality not only protects employees but also enhances overall productivity by fostering a healthier work environment.

2. Compliance with Regulations With stringent environmental regulations in place across many countries, manufacturers are under increasing pressure to minimize their ecological footprint. Carbon air filters help companies comply with these regulations by reducing airborne pollutants that could otherwise result in penalties and legal issues. By investing in advanced filtration systems, manufacturers demonstrate their commitment to sustainable practices.

carbon air filter in roll manufacturers

3. Enhancing Product Quality In roll manufacturing, air quality is directly linked to the quality of the final product. Contamination from airborne particles can lead to defects, inconsistencies, and costly scrap. By utilizing carbon air filters, manufacturers can ensure a cleaner production environment, leading to higher-quality products that meet or exceed customer expectations. This can ultimately enhance the company’s reputation and market competitiveness.

4. Energy Efficiency Carbon air filters contribute to the energy efficiency of manufacturing processes. By maintaining optimal air quality, they reduce the need for additional ventilation systems that consume excess energy. This not only lowers operational costs but also aligns with the broader goal of sustainability, as energy-efficient operations are integral to reducing a company’s carbon footprint.

The Future of Carbon Air Filters in Manufacturing

As industries continue to evolve and prioritize sustainability, the role of carbon air filters in roll manufacturing is likely to expand. Innovations in filter technology, such as enhanced adsorption capabilities and longer lifespan materials, may further improve their effectiveness. Additionally, the integration of smart technology could allow for real-time monitoring of air quality, enabling manufacturers to optimize filtration processes dynamically.

The push for greener practices and cleaner manufacturing will undoubtedly lead to increased adoption of carbon air filters across various sectors. By prioritizing air quality, manufacturers not only comply with regulations but also contribute to the health and well-being of their workforce and the environment.

Conclusion

In conclusion, carbon air filters represent a vital component in the roll manufacturing industry, addressing critical challenges related to air quality, compliance, product integrity, and energy efficiency. As manufacturers strive to innovate sustainably, carbon air filters will continue to play an essential role in the pursuit of cleaner and more responsible production methods. Embracing such technologies not only benefits individual companies but also contributes to broader environmental goals, ultimately fostering a healthier planet for future generations.

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025