Dic . 17, 2024 18:06 Back to list

high quality pltk-16 full-auto 16-station hdaf turntable curing production line

High-Quality PLTK-16 Full-Auto 16-Station HDAF Turntable Curing Production Line Revolutionizing Industrial Efficiency

In the modern industrial landscape, efficiency and productivity are paramount. As businesses strive to optimize their manufacturing processes, innovative solutions such as the High-Quality PLTK-16 Full-Auto 16-Station HDAF Turntable Curing Production Line have emerged as game changers. This advanced production line is engineered to streamline the curing process, enhance product quality, and significantly increase throughput – all critical factors in maintaining competitiveness in today's fast-paced market.

The Ingenious Design of the PLTK-16

At the heart of the PLTK-16 production line is its sophisticated turntable system, which boasts 16 stations designed for high-density automated performance. This design ensures that products move seamlessly through various stages of curing, minimizing idle time and maximizing output. The turntable mechanism allows for continuous operation, leveraging an intelligent layout that reduces transportation delays between stations.

One of the standout features of the PLTK-16 is its high degree of automation. With minimal manual intervention required, the system not only lowers labor costs but also mitigates the risk of human error – a common concern in manufacturing environments. Operators can monitor and control the entire curing process via a user-friendly interface, gaining real-time insights into operational performance, equipment status, and output quality.

Enhanced Curing Capabilities

The curing process is critical for many industrial applications, particularly in the production of composite materials, coatings, and adhesives. The PLTK-16 utilizes an advanced High-Density Auto-Furnace (HDAF) technology that optimally regulates temperature and humidity throughout the curing stations. This precision control ensures uniform curing across all products, resulting in fewer defects and a higher-quality end product.

high quality pltk-16 full-auto 16-station hdaf turntable curing production line

Moreover, the capability to adjust parameters dynamically in response to real-time data provides a level of agility that traditional systems cannot match. Manufacturers can adapt to changes in production demand or variations in material specifications without significant downtime or reconfiguration of the production line.

Integration and Scalability

Another key benefit of the PLTK-16 is its ability to integrate seamlessly with existing manufacturing systems. The line can be easily synced with other processes, such as mixing, molding, or packaging, creating a more cohesive production environment. Additionally, the modular design allows businesses to scale up or down based on their operational needs. Whether a small manufacturer seeking to expand or a large company looking to streamline processes, the PLTK-16 can be customized to meet specific production goals.

Environmental Considerations

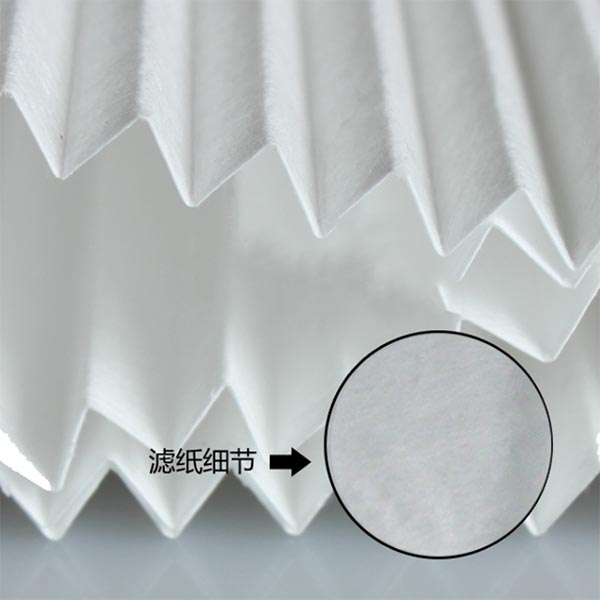

In today's eco-conscious market, sustainability is no longer just a buzzword; it’s a critical component of business strategy. The PLTK-16 addresses this need by incorporating energy-efficient technologies that reduce power consumption without sacrificing performance. Moreover, advanced exhaust and filtration systems minimize emissions and ensure compliance with environmental regulations, making it a responsible choice for manufacturers looking to enhance their green credentials.

Conclusion

The High-Quality PLTK-16 Full-Auto 16-Station HDAF Turntable Curing Production Line epitomizes the cutting-edge solutions available in today’s manufacturing landscape. By enhancing efficiency, improving product quality, and enabling flexible operations, it represents a significant leap forward for industries reliant on precision curing processes. Businesses investing in such advanced technology will not only improve their operational capabilities but also position themselves strategically for future challenges and opportunities in an ever-evolving marketplace. The adoption of the PLTK-16 can undoubtedly drive success and sustainability in the manufacturing sector, ensuring that companies remain at the forefront of innovation and competitiveness.

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025

-

CE Certification Auto/Truck Filter Paper Supplier – Premium Filtration Solutions for Vehicles

NewsJul.06,2025

-

OEM PLGY-500 HDAF Mesh-Ends Hooking and Pressing Machine - High Efficiency, Precision, Reliable Performance

NewsJul.06,2025