Ott . 16, 2024 04:42 Back to list

pp sediment filter making machine

The Evolution of PP Sediment Filter Making Machines

In recent years, advancements in technology have significantly transformed the manufacturing process of various filtration systems, particularly PP (Polypropylene) sediment filters. These filters are widely utilized in water treatment applications to effectively remove sediments and impurities from water sources, contributing to improved water quality. The development of PP sediment filter making machines has played a crucial role in enhancing production efficiency, reducing costs, and ensuring the reliability of the filters produced.

The Evolution of PP Sediment Filter Making Machines

One of the key benefits of modern PP sediment filter making machines is their automation capabilities. These machines integrate advanced technologies, such as computer numerical control (CNC) systems, which allow manufacturers to achieve high precision in the production process. Automation reduces the likelihood of human error, increases production speed, and allows for the consistent quality of filters. As a result, manufacturers can meet the growing demand for filtration solutions in various sectors, including residential, commercial, and industrial applications.

pp sediment filter making machine

Moreover, the machines are designed with environmental sustainability in mind. Many of them incorporate recycling systems that minimize waste during the production process. By reusing offcuts and defects, manufacturers can reduce their environmental footprint while maintaining cost-efficiency. This aligns with the global push towards sustainable manufacturing practices, which are becoming increasingly important in today’s environmentally conscious market.

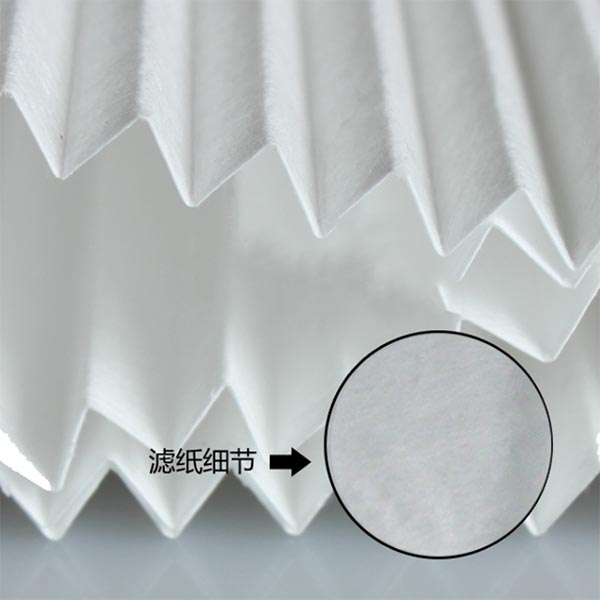

The versatility of PP sediment filter making machines also cannot be overlooked. These machines can produce filters in various sizes and designs, catering to different applications and customer requirements. For instance, they can create deep-pleated filters that optimize the surface area for better filtration efficiency or flat filters for specific applications. This adaptability allows manufacturers to stay competitive in a market that constantly demands innovation and variety.

In addition to their manufacturing capabilities, these machines often come equipped with real-time monitoring and diagnostic systems. These features enable manufacturers to track production performance and identify any potential issues before they escalate. By ensuring the optimal functioning of the machines, manufacturers can significantly reduce downtime and maintenance costs, leading to increased overall productivity.

In conclusion, the advent of PP sediment filter making machines has revolutionized the filtration industry. Through automation, sustainability, and versatility, these machines have enhanced the efficiency and quality of filter production. As the demand for clean and safe water continues to rise worldwide, the importance of reliable sediment filtration systems will only grow. Consequently, ongoing innovations in manufacturing technology will be essential to meet the ever-evolving needs of consumers and industries alike. The future of water filtration, therefore, looks promising, driven by advanced machinery and a commitment to quality and sustainability.

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025