2月 . 10, 2025 10:33 Back to list

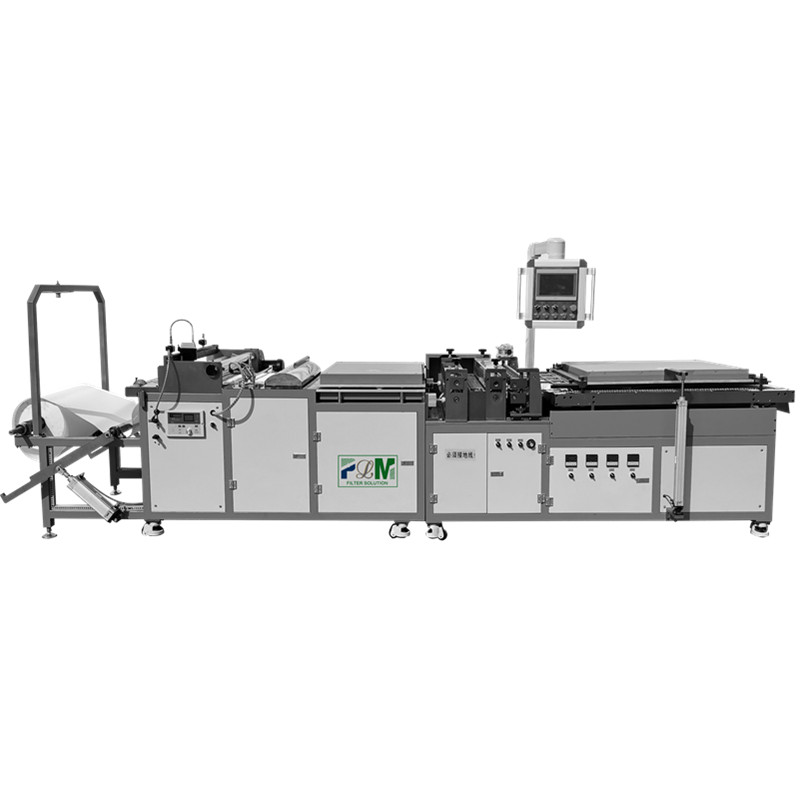

LM-ZZ-5 Drum type air filter origami (800 type)

Fuel filters are an integral component of Caterpillar truck engines, ensuring the longevity and efficiency of these robust machines. These engines, renowned for their power and reliability, require meticulous care and maintenance to operate optimally, especially when employed in demanding conditions such as construction, mining, and heavy transport.

Installation and replacement of Caterpillar fuel filters should follow the manufacturer’s guidelines. Here, detail-oriented expertise is crucial, as incorrect installation can lead to fuel leakage and compromised engine performance. Mechanics specializing in Caterpillar maintenance emphasize the importance of using the correct filtration specifications. This includes understanding micron ratings, which dictate the size of particles the filter can capture, and ensuring compatibility with the specific engine model. There is a plethora of options available in the market, each promising high performance. However, selecting a filter that fits your Caterpillar engine involves careful consideration of factors such as the filter's material quality and filtration ability. Experts advocate for using filters made from high-grade materials that ensure durability and efficiency under strenuous conditions. Also, examining customer reviews and professional endorsements can provide an additional layer of assurance regarding a product’s reliability. Investing in a superior fuel filter is a testament to prioritizing the longevity and efficiency of your Caterpillar engine. While the upfront cost may be higher, the reduction in maintenance issues and enhancement in engine performance make it a cost-efficient choice in the long run. Supporting this claim with testimonials from long-term Caterpillar engine users provides a practical perspective, reinforcing the importance of quality fuel filter selection. Trust is pivotal when discussing the maintenance of complex machinery like Caterpillar truck engines. Dependability on trusted sources for purchasing filters, such as authorized dealers and recognized online platforms, can ensure authenticity. Transparency in product specifications and adherence to manufacturing standards further bolster consumer trust, leading to informed decision-making and optimal engine performance. In essence, the fuel filter for a Caterpillar truck engine is more than a mere component; it is a protective measure that enhances operational efficiency and sustains engine health over time. With the right choice and diligent maintenance, it effectively safeguards the engine's intricate systems, reflecting a profound understanding of the intricate balance between machinery performance and maintenance precision.

Installation and replacement of Caterpillar fuel filters should follow the manufacturer’s guidelines. Here, detail-oriented expertise is crucial, as incorrect installation can lead to fuel leakage and compromised engine performance. Mechanics specializing in Caterpillar maintenance emphasize the importance of using the correct filtration specifications. This includes understanding micron ratings, which dictate the size of particles the filter can capture, and ensuring compatibility with the specific engine model. There is a plethora of options available in the market, each promising high performance. However, selecting a filter that fits your Caterpillar engine involves careful consideration of factors such as the filter's material quality and filtration ability. Experts advocate for using filters made from high-grade materials that ensure durability and efficiency under strenuous conditions. Also, examining customer reviews and professional endorsements can provide an additional layer of assurance regarding a product’s reliability. Investing in a superior fuel filter is a testament to prioritizing the longevity and efficiency of your Caterpillar engine. While the upfront cost may be higher, the reduction in maintenance issues and enhancement in engine performance make it a cost-efficient choice in the long run. Supporting this claim with testimonials from long-term Caterpillar engine users provides a practical perspective, reinforcing the importance of quality fuel filter selection. Trust is pivotal when discussing the maintenance of complex machinery like Caterpillar truck engines. Dependability on trusted sources for purchasing filters, such as authorized dealers and recognized online platforms, can ensure authenticity. Transparency in product specifications and adherence to manufacturing standards further bolster consumer trust, leading to informed decision-making and optimal engine performance. In essence, the fuel filter for a Caterpillar truck engine is more than a mere component; it is a protective measure that enhances operational efficiency and sustains engine health over time. With the right choice and diligent maintenance, it effectively safeguards the engine's intricate systems, reflecting a profound understanding of the intricate balance between machinery performance and maintenance precision.

Latest news

-

Premium HEPA Air Filter for Dyson Parts | Efficient Filtration

NewsAug.04,2025

-

AI-Optimized Active Carbon Filter for Air Purifiers | 51 chars

NewsAug.02,2025

-

Premium Active Carbon Air Filter for Air Purifiers | Odor Removal

NewsAug.01,2025

-

Activated Carbon Air Filters: Ultimate Odor Removal for Purifiers

NewsJul.31,2025

-

PP Spun Filter Cartridge Making Machine for Efficient Filtration Solutions

NewsJul.29,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor & Pollutant Removal

NewsJul.29,2025