თებ . 11, 2025 14:24 Back to list

high quality plastic frame materials

The plastic industry has witnessed tremendous advancements, especially in developing high-quality frame materials. As a product category, plastic frames have turned out to be a remarkable fusion of aesthetics, durability, and environmental considerations, making them a popular choice across various industries, including eyewear, home décor, and electronics.

Professional industries also benefit from innovation in plastic frame development. For instance, the technology sector has immensely benefited from injection-molded frames made of these high-quality plastics. Injection molding enables precision and customization, key for housing delicate electronic components that require structural integrity without the added weight. It affirms the importance of plastics in supporting tech advancements, emphasizing their authority in contributing to technological progress. Industry professionals and organizations play a vital role in maintaining and advancing the standards of plastic frame materials. Through rigorous testing and quality assurance protocols, they create a trustworthy ecosystem where new formulations and composites undergo extensive evaluations to meet safety and quality benchmarks. This continuous pursuit instills confidence among consumers and fortifies the perception of plastic frames as reliable, high-quality products. The expertise reflected in these developments speaks volumes. Multiple studies and decades of industrial experience culminate in improved production processes and material properties, showcasing the refined expertise of scientists, manufacturers, and designers alike. Their role in innovating and executing manufacturing methods ensures products are not only aesthetically pleasing but structurally sound, further bolstering the industry’s authoritative presence. User experiences contribute significantly towards defining quality. Customers across sectors demand products that fulfill their practical needs without compromising on beauty or functionality. High-quality plastic frame materials achieve this balance through superior build quality, finish, and a spectrum of design possibilities, earning trust and loyalty among users. Ultimately, the confluence of these factors – material quality, aesthetic flexibility, sustainability, industry innovation, and user experience – vouch for the unmatched appeal of high-quality plastic frame materials. Their evolution reflects the industry’s commitment to not just meeting but exceeding expectations, delivering reliability and satisfaction across sectors globally. Thus, high-quality plastic frames are not merely functional mediums; they represent a synergy of modern engineering and consumer-centric design principles that empower today’s dynamic lifestyle needs.

Professional industries also benefit from innovation in plastic frame development. For instance, the technology sector has immensely benefited from injection-molded frames made of these high-quality plastics. Injection molding enables precision and customization, key for housing delicate electronic components that require structural integrity without the added weight. It affirms the importance of plastics in supporting tech advancements, emphasizing their authority in contributing to technological progress. Industry professionals and organizations play a vital role in maintaining and advancing the standards of plastic frame materials. Through rigorous testing and quality assurance protocols, they create a trustworthy ecosystem where new formulations and composites undergo extensive evaluations to meet safety and quality benchmarks. This continuous pursuit instills confidence among consumers and fortifies the perception of plastic frames as reliable, high-quality products. The expertise reflected in these developments speaks volumes. Multiple studies and decades of industrial experience culminate in improved production processes and material properties, showcasing the refined expertise of scientists, manufacturers, and designers alike. Their role in innovating and executing manufacturing methods ensures products are not only aesthetically pleasing but structurally sound, further bolstering the industry’s authoritative presence. User experiences contribute significantly towards defining quality. Customers across sectors demand products that fulfill their practical needs without compromising on beauty or functionality. High-quality plastic frame materials achieve this balance through superior build quality, finish, and a spectrum of design possibilities, earning trust and loyalty among users. Ultimately, the confluence of these factors – material quality, aesthetic flexibility, sustainability, industry innovation, and user experience – vouch for the unmatched appeal of high-quality plastic frame materials. Their evolution reflects the industry’s commitment to not just meeting but exceeding expectations, delivering reliability and satisfaction across sectors globally. Thus, high-quality plastic frames are not merely functional mediums; they represent a synergy of modern engineering and consumer-centric design principles that empower today’s dynamic lifestyle needs.

Latest news

-

Premium Active Carbon Air Filters | Odor Removal & Purification

NewsAug.05,2025

-

Premium HEPA Air Filter for Dyson Parts | Efficient Filtration

NewsAug.04,2025

-

AI-Optimized Active Carbon Filter for Air Purifiers | 51 chars

NewsAug.02,2025

-

Premium Active Carbon Air Filter for Air Purifiers | Odor Removal

NewsAug.01,2025

-

Activated Carbon Air Filters: Ultimate Odor Removal for Purifiers

NewsJul.31,2025

-

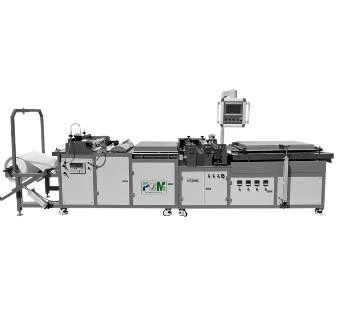

PP Spun Filter Cartridge Making Machine for Efficient Filtration Solutions

NewsJul.29,2025