មករា . 11, 2025 10:29 Back to list

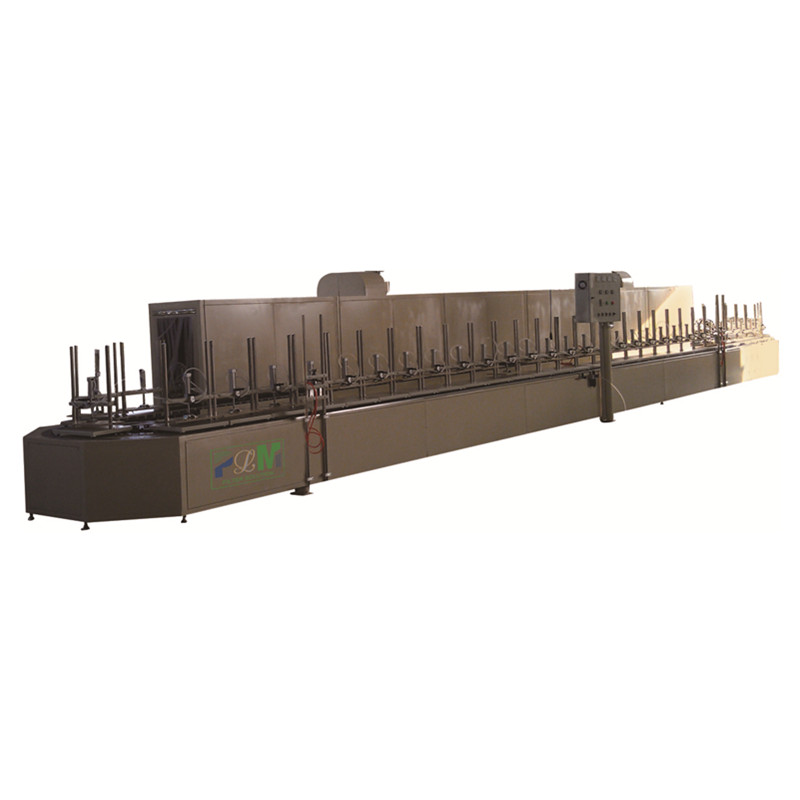

air filter air filter making machine

Ecooil filter producing machines have revolutionized the industry of filtration by offering an efficient, sustainable, and cost-effective solution for various sectors ranging from automotive to industrial applications. These machines embody cutting-edge technology that integrates both environmental considerations and operational excellence, placing them at the forefront of modern manufacturing processes.

Authoritativeness in the ecooil filtration equipment sector is built on years of successful application and continuous improvements. Manufacturers of these machines often work closely with research institutions and engineers to ensure that the latest technological advancements are incorporated. As a result, the machines are not only well-recognized but also highly recommended by industry veterans and experts in publications and industrial workshops. Their reputational strength lies in the machine's delivery of consistently high-quality filters that effectively meet the diverse needs of multiple industries. Trustworthiness is fundamental to the adoption of any new technology, and ecooil filter producing machines excel here due to their reliable performance and comprehensive service support provided by manufacturers. Businesses that adopt these machines report a noticeable enhancement in their operational efficacy and an impressive return on investment due to reduced operational costs and higher product quality. Manufacturers have therefore fostered a robust trust relationship with their clients by ensuring transparency in operations and continuous support through comprehensive training sessions and readily available customer service lines. In conclusion, ecooil filter producing machines represent a significant step forward in sustainable manufacturing technology. As industries seek to minimize their ecological impact while optimizing operations, these machines provide the necessary capabilities to achieve these goals. Whether through improved energy efficiency, superior product quality, or supportive technological infrastructure, ecooil filter producing machines are increasingly being recognized as essential assets for forward-thinking companies aimed at staying ahead of the curve in a competitive landscape.

Authoritativeness in the ecooil filtration equipment sector is built on years of successful application and continuous improvements. Manufacturers of these machines often work closely with research institutions and engineers to ensure that the latest technological advancements are incorporated. As a result, the machines are not only well-recognized but also highly recommended by industry veterans and experts in publications and industrial workshops. Their reputational strength lies in the machine's delivery of consistently high-quality filters that effectively meet the diverse needs of multiple industries. Trustworthiness is fundamental to the adoption of any new technology, and ecooil filter producing machines excel here due to their reliable performance and comprehensive service support provided by manufacturers. Businesses that adopt these machines report a noticeable enhancement in their operational efficacy and an impressive return on investment due to reduced operational costs and higher product quality. Manufacturers have therefore fostered a robust trust relationship with their clients by ensuring transparency in operations and continuous support through comprehensive training sessions and readily available customer service lines. In conclusion, ecooil filter producing machines represent a significant step forward in sustainable manufacturing technology. As industries seek to minimize their ecological impact while optimizing operations, these machines provide the necessary capabilities to achieve these goals. Whether through improved energy efficiency, superior product quality, or supportive technological infrastructure, ecooil filter producing machines are increasingly being recognized as essential assets for forward-thinking companies aimed at staying ahead of the curve in a competitive landscape.

Latest news

-

PLAB-6 A B Filter Gluing Machine - Hebei Filter Man

NewsAug.14,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man Automotive Parts Trading Co., Ltd.|Adjustable Speed&Step Motor Control

NewsAug.14,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man|Precision Gluing, Automated Efficiency

NewsAug.14,2025

-

Premium Active Carbon Air Filter for Purifiers - Breathe Clean!

NewsAug.14,2025

-

PLAB-6 A B Compound Filter Gluing Machine - Hebei Filter Man

NewsAug.13,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man|Precision Gluing&Industrial Automation

NewsAug.13,2025