មករា . 17, 2025 04:54 Back to list

PLPM-1210 Fully Automatic Printing Machine

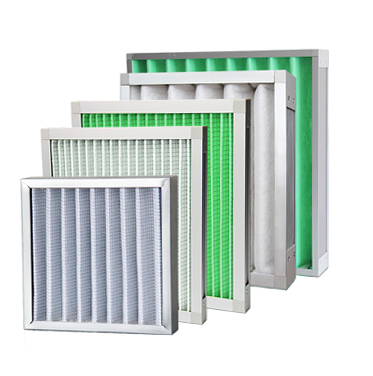

Gas turbine air filters are a pivotal component in ensuring the longevity, efficiency, and operational integrity of gas turbines across various industries, including power generation and aviation. These filters serve as the first line of defense against contaminants that can compromise the performance of high-value turbines whose reliability is crucial for seamless operations.

Authoritativeness in gas turbine air filtration can be illustrated by relying on standards set by industry bodies like the International Organization for Standardization (ISO). Ensuring the filters meet or exceed the ISO standards guarantees a baseline of quality and reliability that operators can trust. Furthermore, industry experts often recommend conducting regular efficiency tests and replacing filters proactively based on analytics-driven insights rather than fixed schedules, ensuring uninterrupted efficiency. Trustworthiness in the selection and maintenance of gas turbine air filters is achieved through partnerships with reputable suppliers known for their expertise and innovation. Analyzing supplier track records and customer testimonials can provide invaluable insights into quality and performance. Moreover, collaboration with manufacturers that offer personalized support and service guarantees continuity and reliability, which are crucial for industries where any downtime translates to significant operational losses. Case studies underscore how companies that implemented predictive maintenance programs — where analytics and real-time monitoring predict filter replacements — have observed noticeable improvements in turbine performance and a decline in unscheduled maintenance. Such applications of data analytics in filtration management highlight the evolution from traditional periodic maintenance toward a more dynamic, performance-based approach. Incorporating advanced filtration solutions not only protects the physical components of the turbines but also optimizes their performance by enabling them to run at intended efficiencies with minimal interruptions. The impact is reflected in improved energy efficiency and reduced environmental impact. In closing, the selection, installation, and maintenance of gas turbine air filters play a critical role in ensuring operational efficiency across industries. By understanding the specific requirements of their environments and utilizing comprehensive strategies integrating advanced filtration technologies, businesses can optimize their performance outputs while reducing operational costs and minimizing environmental footprints. Investing in high-quality air filters is not just an operational necessity but also a strategic decision with long-term benefits.

Authoritativeness in gas turbine air filtration can be illustrated by relying on standards set by industry bodies like the International Organization for Standardization (ISO). Ensuring the filters meet or exceed the ISO standards guarantees a baseline of quality and reliability that operators can trust. Furthermore, industry experts often recommend conducting regular efficiency tests and replacing filters proactively based on analytics-driven insights rather than fixed schedules, ensuring uninterrupted efficiency. Trustworthiness in the selection and maintenance of gas turbine air filters is achieved through partnerships with reputable suppliers known for their expertise and innovation. Analyzing supplier track records and customer testimonials can provide invaluable insights into quality and performance. Moreover, collaboration with manufacturers that offer personalized support and service guarantees continuity and reliability, which are crucial for industries where any downtime translates to significant operational losses. Case studies underscore how companies that implemented predictive maintenance programs — where analytics and real-time monitoring predict filter replacements — have observed noticeable improvements in turbine performance and a decline in unscheduled maintenance. Such applications of data analytics in filtration management highlight the evolution from traditional periodic maintenance toward a more dynamic, performance-based approach. Incorporating advanced filtration solutions not only protects the physical components of the turbines but also optimizes their performance by enabling them to run at intended efficiencies with minimal interruptions. The impact is reflected in improved energy efficiency and reduced environmental impact. In closing, the selection, installation, and maintenance of gas turbine air filters play a critical role in ensuring operational efficiency across industries. By understanding the specific requirements of their environments and utilizing comprehensive strategies integrating advanced filtration technologies, businesses can optimize their performance outputs while reducing operational costs and minimizing environmental footprints. Investing in high-quality air filters is not just an operational necessity but also a strategic decision with long-term benefits.

Latest news

-

PLAB-6 A B Compound Filter Gluing Machine - Hebei Filter Man

NewsAug.13,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man|Precision Gluing&Industrial Automation

NewsAug.13,2025

-

PLAB-6 A/B Gluing Machine-Hebei Filter Man|Precision Gluing&Efficient Adhesive Application

NewsAug.13,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man|Precision Gluing, Industrial Filtration

NewsAug.13,2025

-

Premium Active Carbon Air Filter for Air Purifier - Odor & VOCs

NewsAug.13,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine - Hebei Filter Man

NewsAug.12,2025