ធ្នូ . 21, 2024 20:38 Back to list

high quality eco oil filter making machine

High-Quality Eco Oil Filter Making Machine Revolutionizing the Industry

In an era where environmental consciousness is paramount, the demand for eco-friendly products is surging. One sector that has felt the impact of this eco-revolution is the oil filtration industry. The drive for sustainability has necessitated the development of specialized equipment aimed at producing high-quality eco oil filters. The high-quality eco oil filter making machine has emerged as a game changer, combining efficiency, durability, and eco-friendliness.

The Importance of Eco Oil Filters

Oil filters play a critical role in maintaining the performance and longevity of engines by removing impurities, contaminants, and particles from the oil. Traditional oil filters, while effective, often contribute to environmental issues due to their materials and disposal methods. In contrast, eco oil filters are designed with sustainability in mind, using recyclable materials and promoting better disposal practices. As the automotive and industrial sectors increasingly prioritize eco-friendliness, the demand for high-quality eco oil filters is on the rise.

Features of High-Quality Eco Oil Filter Making Machines

High-quality eco oil filter making machines are specifically engineered to produce filters that meet rigorous environmental standards. Here are some of the key features that make these machines a top choice for manufacturers

1. Advanced Technology Utilizing cutting-edge technology, these machines ensure precision in the manufacturing process. This includes automated systems for filtering, shaping, and assembling components, which enhances product quality and minimizes waste.

2. Energy Efficiency Eco oil filter making machines are designed to consume less energy during operation, reducing the carbon footprint of the manufacturing process. This efficiency not only helps the environment but also lowers operational costs for manufacturers.

high quality eco oil filter making machine

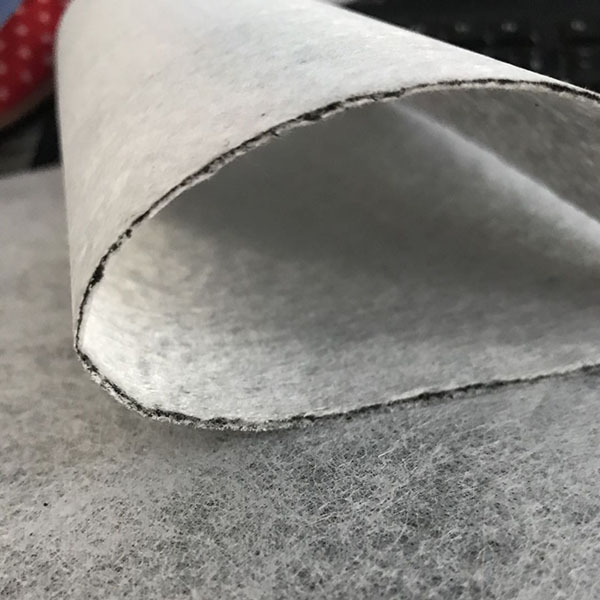

3. Material Versatility These machines can work with a variety of sustainable materials, including biodegradable plastics and recycled fibers. This adaptability allows manufacturers to cater to different markets while maintaining a focus on sustainability.

4. User-Friendly Interface High-quality machines often come equipped with user-friendly interfaces that simplify operation. Manufacturers can easily adjust settings and monitor production processes, which improves overall productivity.

5. Robust Construction Built with durable materials, these machines are designed to withstand the rigors of industrial use. Their reliability ensures continuous operation, which is vital for meeting high production demands.

The Benefits of Investing in Eco Oil Filter Making Machines

Investing in a high-quality eco oil filter making machine presents numerous advantages for manufacturers. Firstly, it aligns with global sustainability goals, tapping into the growing market for eco-friendly products. Secondly, by producing superior oil filters, manufacturers can enhance their reputation and attract environmentally-conscious customers.

Moreover, these machines facilitate compliance with stringent environmental regulations, reducing risks associated with non-compliance. The capacity to innovate and produce advanced filters can also lead to competitive advantages in a crowded market.

Conclusion

The surge in demand for eco oil filters is reshaping the oil filtration industry. High-quality eco oil filter making machines are at the forefront of this transformation, combining efficiency, sustainability, and advanced technology. By investing in these machines, manufacturers not only contribute to environmental sustainability but also position themselves for success in a rapidly evolving market. As society continues to prioritize eco-friendly solutions, the role of these innovative machines will become increasingly critical in defining the future of the industry.

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025