ធ្នូ . 31, 2024 22:27 Back to list

Top Oil Filter Manufacturers and Their Quality Products for Your Vehicle Needs

The Importance of Oil Filter Manufacturers in the Automotive Industry

In today's fast-paced automotive industry, oil filter manufacturers play a pivotal role in ensuring the efficient performance and longevity of vehicles. With the increasing complexity of automotive engines and the need for higher fuel efficiency, the significance of high-quality oil filters cannot be overstated. This article delves into the critical functions of oil filters, the manufacturing processes involved, and the key players in this industry.

Understanding the Function of Oil Filters

Oil filters are essential components in any internal combustion engine. Their primary function is to remove contaminants from engine oil, preventing these impurities from circulating throughout the engine. Without a reliable oil filter, dirt, metal particles, and other debris can accumulate, leading to increased engine wear and potentially catastrophic failures. A clean oil supply is vital for maintaining optimal lubrication, enhancing engine performance, and extending the lifespan of critical components.

In modern vehicles, oil filters not only capture particulate matter but also play a role in removing oxidation products that occur from the oil’s exposure to high temperatures. As engines become more efficient and compact, the demands placed on oil filters increase. Consequently, manufacturers are constantly innovating to meet these stringent requirements.

Manufacturing Process and Quality Control

The manufacturing process of oil filters is intricate and requires precision. It typically begins with the selection of high-quality raw materials such as base materials for filter media and robust metal casings. The filter media must be capable of trapping a wide range of particles while allowing for optimal oil flow. Fiberglass is a common choice for filter media due to its superior filtration capabilities.

Once the materials are selected, the manufacturing process involves several key steps

1. Media Production The filter media is produced through a careful process that ensures its efficiency and durability. This often includes creating layers of different materials to capture a broad spectrum of impurities.

oil filter manufacturers

2. Assembling Filters are assembled in a controlled environment to prevent contamination during the production process. The various components—a filter casing, media, and anti-drain back valves—are brought together through automated processes to ensure consistency.

3. Testing Quality control is paramount in oil filter manufacturing. Filters undergo rigorous testing to ensure they meet industry standards for performance and durability. This includes pressure testing, flow rate evaluations, and fatigue testing to simulate real-world conditions.

4. Certification Many manufacturers seek certifications from industry bodies to demonstrate the quality and reliability of their products. This can include certifications from organizations such as the Society of Automotive Engineers (SAE) and other relevant automotive quality standards.

Key Players in the Oil Filter Industry

The oil filter market is populated by a mix of established companies and innovative newcomers. Major players include brands like Wix Filters, Fram, and Bosch, each with a reputation for producing reliable products that meet the demands of various vehicles – from everyday commuters to high-performance sports cars.

Moreover, the rise of electric vehicles (EVs) and hybrid models is prompting manufacturers to adapt their products. While traditional oil filters are crucial for combustion engines, the shift towards more complex powertrains requires filters that can handle new types of lubricants and operational environments.

Conclusion

In conclusion, oil filter manufacturers are at the heart of the automotive industry, providing essential components that promote engine health and performance. As technology advances and consumer demands evolve, these manufacturers must continually innovate to ensure their products meet the highest standards. The ongoing development in filtration technology will not only enhance vehicle efficiency but also contribute to a more sustainable future in automotive engineering. Thus, the role of oil filter manufacturers remains crucial as we drive towards smarter, more efficient automotive solutions.

-

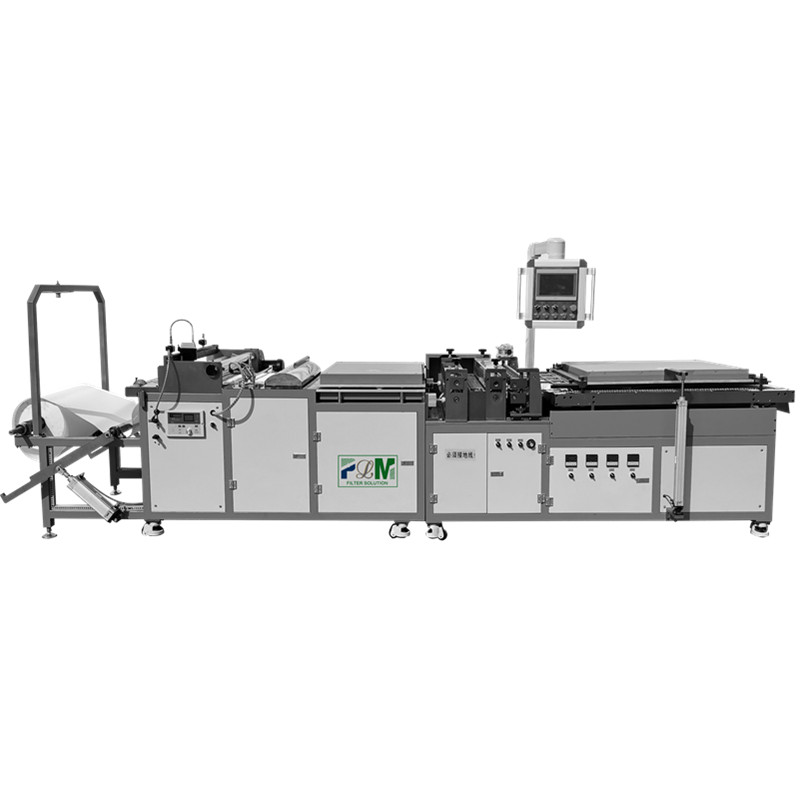

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025