វិច្ឆិកា . 08, 2024 10:25 Back to list

Non-Woven Pleating and Carding Machine for Efficient Textile Production

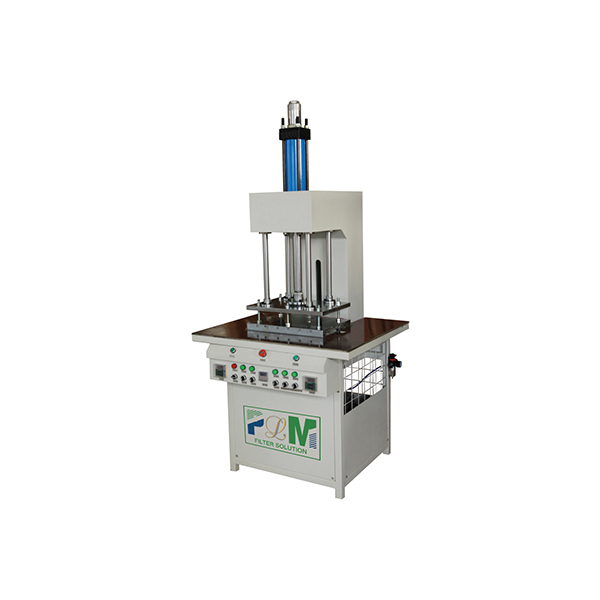

The Importance of PLRB-1 Non-Woven Pleats Carding Machine in Industrial Applications

In modern manufacturing, the efficiency and effectiveness of production processes are paramount. Among the many innovations that have revolutionized the textile industry, the PLRB-1 Non-Woven Pleats Carding Machine stands out as a significant contributor to the production of high-quality non-woven fabrics. This advanced machine plays a pivotal role in transforming raw materials into versatile products used across various sectors, including automotive, healthcare, and fashion.

Understanding the Non-Woven Fabric Production Process

Non-woven fabrics are engineered by bonding fibers together rather than weaving them. This process offers advantages such as reduced production time and improved fabric properties. The carding stage is crucial in this process, as it serves to separate, align, and prepare fibers for subsequent bonding. The PLRB-1 model excels in this area, utilizing cutting-edge technology to optimize the carding phase.

Key Features of the PLRB-1 Non-Woven Pleats Carding Machine

The PLRB-1 is designed with several features that enhance its performance. First and foremost, it incorporates a high-speed carding system that efficiently processes large volumes of fibers. This capability is essential for meeting the demands of high-volume production environments.

Moreover, the machine is equipped with advanced control systems that allow for precise adjustments of settings such as fiber feed rates and carding intensity. This level of control enables manufacturers to tailor the fabric characteristics to suit specific applications. For instance, a softer finish may be desired for healthcare applications, while a more robust fabric could be required for automotive interiors.

The durability and reliability of the PLRB-1 also contribute to its appeal. Constructed from high-quality materials, it is built to withstand the rigors of continuous operation, thereby reducing downtime due to maintenance issues. Additionally, the machine’s user-friendly interface simplifies operation, allowing workers to quickly adapt to new processes and minimizing training time.

plrb-1 non-woven pleats-carding macine product

Applications of Non-Woven Fabrics

The versatility of non-woven fabrics produced by the PLRB-1 carding machine allows them to be used in a myriad of applications. In the healthcare sector, non-woven materials are essential for manufacturing products such as surgical masks, gowns, and disposable bedding. These materials provide barriers against pathogens while ensuring comfort for the wearer.

In the automotive industry, non-woven fabrics are increasingly used for interior components, insulation, and soundproofing. Their lightweight nature and ability to absorb sound make them ideal for enhancing passenger comfort and reducing vehicle weight for better fuel efficiency.

Fashion and consumer products also benefit from non-woven technology. Non-woven bags, for instance, are an eco-friendly alternative to plastic, appealing to environmentally conscious consumers. Furthermore, the aesthetic properties of non-woven fabrics are leveraged in various fashion accessories and home décor items.

The Future of Non-Woven Fabric Production

As sustainability becomes a central theme in manufacturing, the PLRB-1 Non-Woven Pleats Carding Machine plays a critical role in the evolution of the textile industry. Innovations in this technology will likely focus on increasing energy efficiency and the recyclability of non-woven materials.

Furthermore, the demand for non-woven products is expected to grow, driven by advancements in product applications and an expanding market. The adaptability of the PLRB-1 will allow manufacturers to respond effectively to these changes, ensuring they remain competitive in a rapidly evolving industry.

In conclusion, the PLRB-1 Non-Woven Pleats Carding Machine exemplifies the crucial advancements in textile machinery that enhance production capabilities. Its features address both efficiency and quality, making it an invaluable asset across multiple sectors. As the industry continues to evolve, the PLRB-1 is set to remain at the forefront of non-woven fabric production, contributing to exciting innovations and sustainable practices in manufacturing.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025