តុលា . 07, 2024 05:45 Back to list

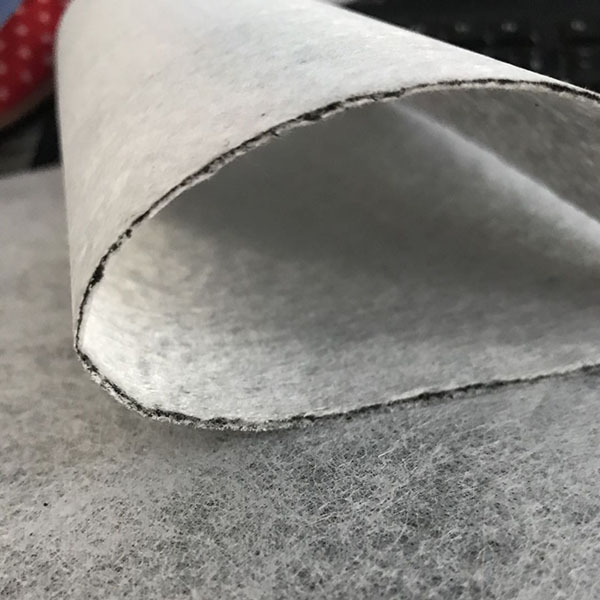

pu-20f full-auto casting machine on seal packing in filter element manufacturer

The Advancements in the PU-20F Full-Auto Casting Machine for Seal Packing in Filter Element Manufacturing

In the thriving world of manufacturing, efficiency and precision are paramount, especially in industries such as filter element production. The introduction of the PU-20F Full-Auto Casting Machine marks a significant leap forward in streamlining the seal packing process, enhancing productivity, and ensuring quality in filter manufacturing.

Understanding the PU-20F Full-Auto Casting Machine

The PU-20F Full-Auto Casting Machine is designed to automate the intricate task of seal packing within filter elements. The machine’s automation capabilities drastically reduce the labor intensity that typically accompanies manual packing processes. By integrating advanced technology, the PU-20F ensures that filter elements are sealed with high precision, minimizing the risk of inconsistencies that could lead to product failures.

One of the standout features of the PU-20F is its ability to handle various types of seal materials. This versatility allows manufacturers to cater to different market demands without the need for extensive machinery investment or alteration. The machine accommodates a range of polymers and sealants, making it an indispensable tool for modern filter element manufacturers.

Efficiency and Speed

Time is money in the manufacturing sector, and the PU-20F is engineered to maximize both. The automation provided by the machine leads to a significant increase in production speed. Upon receiving the raw filter element, the PU-20F can execute the casting of seals at an unprecedented rate, thereby supporting manufacturers in meeting high volume demands. It is capable of operating continuously, which allows for longer production runs without the downtime often associated with manual processes.

Additionally, this enhanced speed does not compromise the quality of the end product. The PU-20F employs cutting-edge sensors and monitoring systems to ensure each seal is applied with consistent pressure and precision. This attention to detail ensures that every filter element meets the rigorous quality standards required in various applications, including automotive, industrial, and consumer goods.

Quality Assurance

pu-20f full-auto casting machine on seal packing in filter element manufacturer

In manufacturing, especially in filtering solutions where reliability is crucial, the consistency and integrity of the seals can directly influence the performance of the filter elements. The PU-20F employs an array of quality assurance mechanisms designed to catch any anomalies in the seal application process. Real-time monitoring ensures that any deviation from the specified parameters is immediately addressed, thereby reducing waste and ensuring product quality.

Moreover, the machine is designed to facilitate easy integration with existing manufacturing workflows. This adaptability can be a game-changer for manufacturers looking to upgrade their operations without a complete overhaul of their systems.

Environmental Considerations

With the growing emphasis on sustainability, manufacturers are increasingly looking for ways to minimize their environmental impact. The PU-20F aligns with these goals by optimizing material usage and reducing waste associated with traditional sealing processes. By streamlining the application, the amount of excess material can be significantly decreased, making the process more sustainable while also cutting costs.

Furthermore, the machine’s energy-efficient design means it consumes less power than conventional counterparts, which not only promotes environmental sustainability but also leads to reduced operational costs.

Conclusion

The PU-20F Full-Auto Casting Machine represents a significant advancement in the manufacturing of filter elements, combining efficiency, precision, and sustainability into one comprehensive package. As industries continue to demand higher quality and greater efficiency, investing in such advanced machinery will undoubtedly yield substantial returns.

Manufacturers who adopt the PU-20F can expect enhanced productivity, improved quality assurance, and a stronger alignment with environmental sustainability goals. As technology continues to evolve, the PU-20F stands as a testament to the innovations shaping the future of industrial manufacturing processes. In a world where every second and every resource counts, embracing such cutting-edge solutions will pave the way for success in today’s competitive landscape.

-

Premium OEM Snus Paper Supplier Custom Snus Filter & Packing Papers for Your Brand

NewsJul.05,2025

-

CE Certification PLJL-6 Six-Station Seal Leakage Tester for Spin-On Filter – High Efficiency & Reliability

NewsJul.05,2025

-

OEM PLXB-1 PU Pack Trimming Machine - Precision Cutting, High Efficiency, Reliable Quality

NewsJul.05,2025

-

Premium Engine Oil Filter Supplier & Exporter Reliable Engine Oil Filter Service

NewsJul.04,2025

-

Wholesale PLRZ-1000N Full-Auto Hot Melt Filter Paper Bonding Machine - High Efficiency & Precision

NewsJul.04,2025

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025