វិច្ឆិកា . 25, 2024 10:40 Back to list

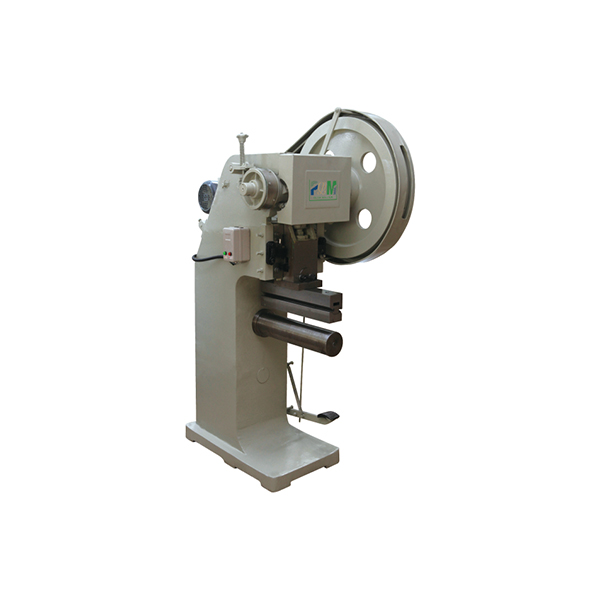

Screw Press for Efficient Dewatering Solutions in Industrial Applications

The Screw Press Dewatering Device An Innovative Solution for Wastewater Management

In the realm of wastewater management and industrial dewatering processes, the screw press dewatering device has emerged as a groundbreaking tool

. This equipment is specifically designed to efficiently separate liquids from solids, making it an essential component in various industries, including food processing, sludge treatment, and agricultural waste management.The fundamental operating principle of a screw press dewatering device is relatively simple yet highly effective. It employs a rotating screw mechanism housed within a cylindrical screen. As the feed material enters the device, the screw conveyor moves it through the screen. The increasing pressure created by the screw's rotation forces the liquid out, allowing for the solid material to be compacted and discharged. This process not only minimizes the volume of waste but also recovers valuable water, making it an environmentally friendly option.

One of the primary advantages of the screw press dewatering device is its versatility. It can handle a wide range of materials, from food waste and biomass to municipal sludge and industrial effluents. This flexibility makes it an attractive choice for facilities looking to optimize their waste management processes. Moreover, the adjustable settings of the device allow operators to tailor the dewatering conditions to meet specific requirements, resulting in optimized performance and efficiency.

screw press dewatering device product

Another significant benefit of using a screw press is its low energy consumption compared to traditional dewatering methods, such as centrifuges or filter presses. This efficiency not only reduces operational costs but also minimizes the carbon footprint associated with wastewater treatment processes. Additionally, the continuous operation of the screw press ensures a steady flow of dewatered materials, contributing to a more streamlined production process.

Durability and low maintenance are other noteworthy characteristics of screw press dewatering devices. Constructed from robust materials, these devices are designed to withstand the demanding conditions often encountered in wastewater treatment facilities. Their simplicity in design further contributes to ease of maintenance, allowing for quick inspections and repairs, which can significantly reduce downtime.

Furthermore, the adoption of screw press technology aligns with the growing trend of circular economy principles. By facilitating the recovery of valuable resources from waste, such as water and organic fertilizers, industries can reduce their reliance on fresh resources and promote sustainability.

In conclusion, the screw press dewatering device represents a transformative advancement in the field of dewatering technology. With its efficiency, versatility, and environmental benefits, it plays a crucial role in modern wastewater management practices. As industries continue to prioritize sustainability and resource recovery, the screw press is poised to become an invaluable asset in achieving these goals. The integration of such innovative solutions is not just a trend but a necessity in the quest for a cleaner and more sustainable future.

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025