មករា . 10, 2025 09:04 Back to list

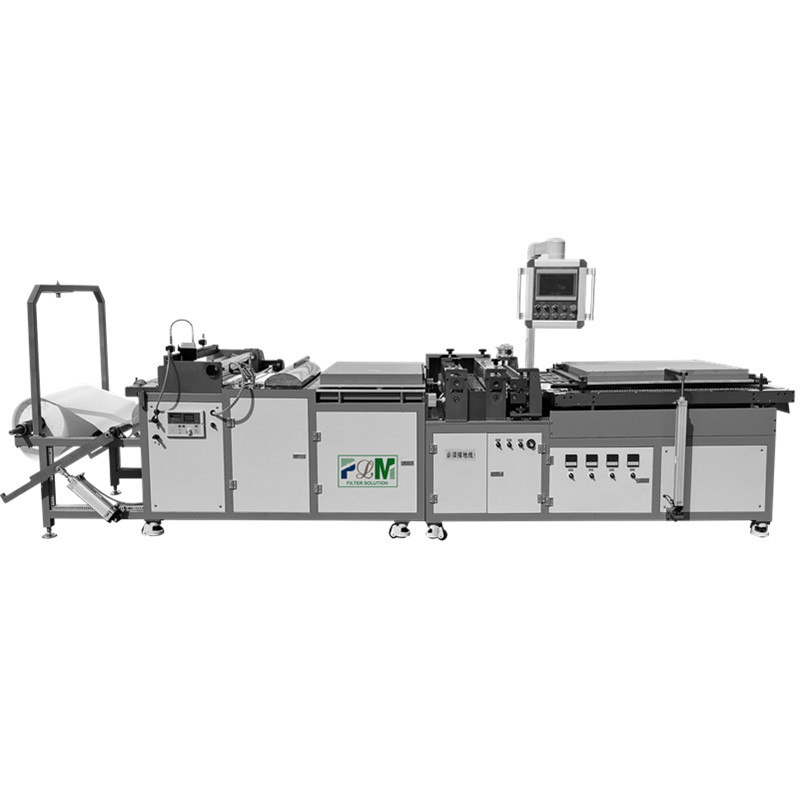

truck air filters making machine

In the realm of heavy-duty vehicles, maintaining optimal performance is crucial. Truck air filters play a vital role in ensuring engines run smoothly by preventing harmful particles from entering. Behind these essential components is a sophisticated manufacturing process driven by advanced machinery. The demand for truck air filter making machines has been on the rise, thanks to the increasing emphasis on vehicle efficiency and emission norms.

Trustworthiness and reliability are non-negotiable when it comes to machinery that supports the automotive industry. Manufacturers of truck air filter making machines prioritize rigorous quality control protocols. Machines are subjected to extensive testing, simulating real-world manufacturing conditions to ensure they meet both industry standards and customer expectations. This commitment to quality not only reinforces the machine's longevity but also ensures the end products' effectiveness in various environmental conditions. Furthermore, the authority of manufacturers often stems from their dedication to customer support and knowledge sharing. Providing comprehensive training programs and technical support ensures that operators can maximize the machine's potential. A reliable manufacturer will not only deliver a state-of-the-art machine but also become a partner in a client's success, guiding them through setup, operation, and maintenance challenges. In a competitive market, making an informed investment in a truck air filter making machine can set a business apart. By choosing a partner known for their expertise and commitment to quality, companies can ensure they produce filters that not only meet but exceed industry standards. Such a venture is not merely about acquiring a piece of equipment; it’s about aligning with a trusted authority in the field, enhancing both product quality and market reputation. In conclusion, the world of truck air filter manufacturing is a testament to the fusion of technology, expertise, and strategic foresight. Selecting the right machine involves more than an understanding of its mechanics; it requires a partnership with a manufacturer who embodies experience, professionalism, and a commitment to excellence. Such partnerships pave the way for innovation in filter manufacturing, driving the industry forward and ensuring longevity in the ever-evolving automotive landscape.

Trustworthiness and reliability are non-negotiable when it comes to machinery that supports the automotive industry. Manufacturers of truck air filter making machines prioritize rigorous quality control protocols. Machines are subjected to extensive testing, simulating real-world manufacturing conditions to ensure they meet both industry standards and customer expectations. This commitment to quality not only reinforces the machine's longevity but also ensures the end products' effectiveness in various environmental conditions. Furthermore, the authority of manufacturers often stems from their dedication to customer support and knowledge sharing. Providing comprehensive training programs and technical support ensures that operators can maximize the machine's potential. A reliable manufacturer will not only deliver a state-of-the-art machine but also become a partner in a client's success, guiding them through setup, operation, and maintenance challenges. In a competitive market, making an informed investment in a truck air filter making machine can set a business apart. By choosing a partner known for their expertise and commitment to quality, companies can ensure they produce filters that not only meet but exceed industry standards. Such a venture is not merely about acquiring a piece of equipment; it’s about aligning with a trusted authority in the field, enhancing both product quality and market reputation. In conclusion, the world of truck air filter manufacturing is a testament to the fusion of technology, expertise, and strategic foresight. Selecting the right machine involves more than an understanding of its mechanics; it requires a partnership with a manufacturer who embodies experience, professionalism, and a commitment to excellence. Such partnerships pave the way for innovation in filter manufacturing, driving the industry forward and ensuring longevity in the ever-evolving automotive landscape.

Latest news

-

PLAB-6 A B Filter Gluing Machine - Hebei Filter Man

NewsAug.14,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man Automotive Parts Trading Co., Ltd.|Adjustable Speed&Step Motor Control

NewsAug.14,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man|Precision Gluing, Automated Efficiency

NewsAug.14,2025

-

Premium Active Carbon Air Filter for Purifiers - Breathe Clean!

NewsAug.14,2025

-

PLAB-6 A B Compound Filter Gluing Machine - Hebei Filter Man

NewsAug.13,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man|Precision Gluing&Industrial Automation

NewsAug.13,2025