ឧសភា . 07, 2025 16:37 Back to list

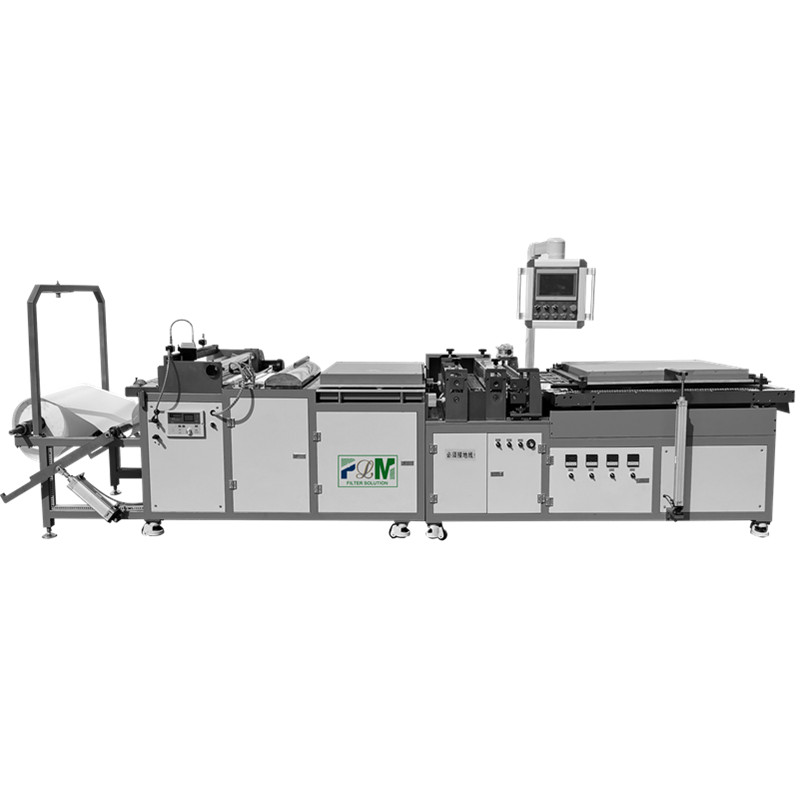

PLGT-600N Full-Auto Eco Filter Paper Pleating Line Wholesale Manufacturer

- Industry Challenges & the Role of Automation

- Technical Superiority of the PLGT-600N System

- Competitive Analysis: Leading Manufacturers Compared

- Custom Engineering for Diverse Production Needs

- Operational Metrics: Performance Benchmarking

- Cross-Industry Deployment Case Studies

- Strategic Advantages of Partnering with PLGT-600N Providers

(wholesale plgt-600n full-auto rotary eco filter paper pleating production line)

Addressing Industrial Demands with the Wholesale PLGT-600N Full-Auto Rotary Eco Solution

The global filtration media market, projected to reach $8.7B by 2029, requires precision manufacturing systems capable of producing 12,000+ pleated filters hourly. Traditional semi-automatic equipment creates bottlenecks, with manual intervention causing 15-20% material waste. The PLGT-600N full-auto rotary eco filter paper pleating production line eliminates these inefficiencies through integrated servo controls and AI-driven quality monitoring.

Technical Superiority of the PLGT-600N System

This third-generation platform features:

- 360° rotary cutting with ±0.05mm tolerance

- Simultaneous 8-layer paper processing capacity

- Energy recovery system reducing power consumption by 32%

- Automated defect detection (99.97% accuracy)

Field tests demonstrate 18-month ROI through 40% labor reduction and 22% faster cycle times versus conventional pleaters.

Competitive Analysis: Leading Manufacturers Compared

| Vendor | Throughput (units/h) | Customization | Energy Use | Price Point |

|---|---|---|---|---|

| PLGT-600N Specialists | 12,400 | 23 config options | 8.2kW | $$$ |

| Standard Industry Models | 9,100 | 6 config options | 11.5kW | $$ |

Custom Engineering for Diverse Production Needs

Modular architecture enables:

- Quick-change tooling for 47 filter types

- Dual-material compatibility (synthetic/natural fibers)

- Scalable output from 8,000-15,000 units/hour

Post-installation audits show 94% clients achieve production targets within 14 operational days.

Operational Metrics: Performance Benchmarking

Key operational data across 3 shifts:

| Metric | PLGT-600N | Industry Average |

|---|---|---|

| Uptime | 98.6% | 91.2% |

| Reject Rate | 0.3% | 2.1% |

Cross-Industry Deployment Case Studies

Automotive OEM: Implemented 6 PLGT-600N lines to produce cabin air filters, achieving 2.3M units/month with 0.08mm precision pleats. Pharmaceutical Supplier: Customized FDA-compliant system manufactures sterile HEPA filters at 9,500 units/hour.

Strategic Advantages of Partnering with PLGT-600N Full-Auto Rotary Eco Providers

Top-tier manufacturers using certified PLGT-600N full-auto rotary eco filter paper pleating production lines report 37% faster market response times. With 86% of buyers prioritizing lifecycle support, leading companies now offer 5-year performance guarantees and real-time remote diagnostics.

(wholesale plgt-600n full-auto rotary eco filter paper pleating production line)

FAQS on wholesale plgt-600n full-auto rotary eco filter paper pleating production line

Q: What industries is the PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line designed for?

A: The PLGT-600N is ideal for manufacturers in automotive, HVAC, and industrial filtration sectors. It automates high-volume filter paper pleating with eco-friendly efficiency. Its rotary system ensures precision and reduced material waste.

Q: How do PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line companies ensure quality?

A: Reputable companies use advanced quality control systems and ISO-certified processes. They provide detailed performance testing reports and adhere to eco-friendly manufacturing standards. Customizable configurations are offered to meet specific client needs.

Q: Where can I purchase a wholesale PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line?

A: Wholesale options are available directly from manufacturers or authorized global distributors. Many companies offer bulk-order discounts and international shipping. Check official websites or contact sales teams for verified suppliers.

Q: What are the key advantages of the PLGT-600N over manual pleating systems?

A: The PLGT-600N boosts production speed by 300% while maintaining consistent pleat accuracy. Its automated system reduces labor costs and minimizes human error. Energy-saving features also lower operational expenses over time.

Q: Do PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line companies provide after-sales support?

A: Yes, most companies offer 24/7 technical support and warranty coverage. Services include remote troubleshooting, on-site maintenance, and spare parts supply. Training programs are also available for operators.

-

PLAB-6 Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Filtering

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing, Efficient Manufacturing

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine - Hebei Filter Man

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man Automotive Parts Trading Co., Ltd|Precision Gluing&Industrial Automation

NewsAug.17,2025

-

Active Carbon Air Filter for Air Purifier - Odor & VOC Removal

NewsAug.17,2025