11월 . 17, 2024 02:12 Back to list

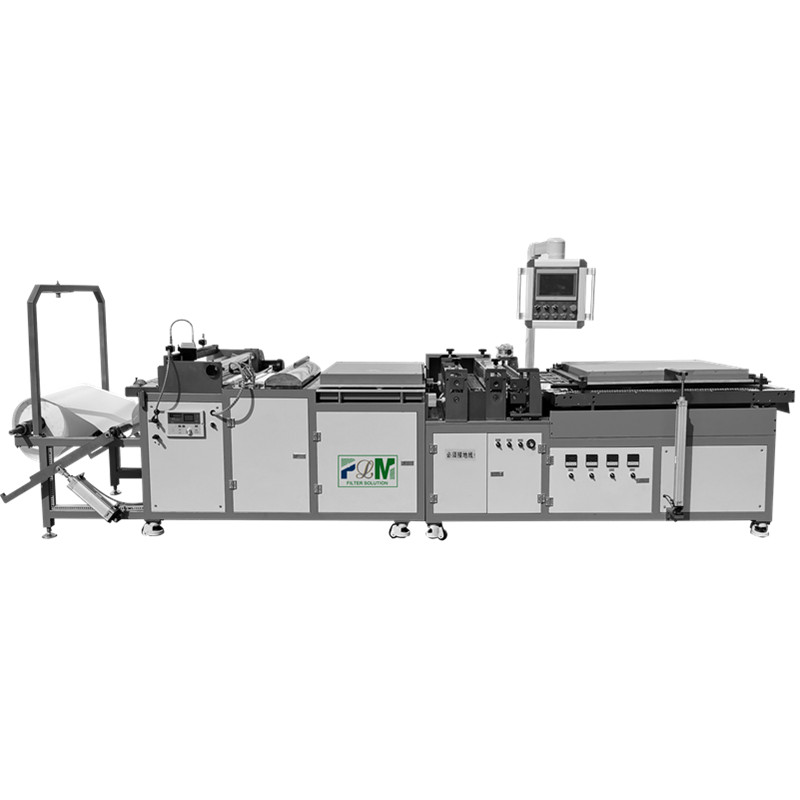

Full Automatic Ultrasonic Welding Machine for PLC Filter Element Production

The Advancements of Full-Auto Filter Element Ultrasonic Welding Machines

In today’s manufacturing landscape, efficiency and precision are paramount. One technology that has gained significant attention is the use of full-auto ultrasonic welding machines specifically designed for filter elements. These machines have revolutionized the way filter components are produced, providing consistent quality and reduced production times.

Ultrasonic welding is a process that uses high-frequency ultrasonic acoustic vibrations to join materials, typically plastics or metals, without the need for additional adhesives or fasteners. This technique is particularly beneficial in the production of filter elements, where the assembly of various parts must be achieved without compromising the integrity of the components. The full-auto design of these machines means that the entire process, from feeding materials to finished product output, is automated, significantly minimizing human error and labor costs.

One of the key advantages of purchasing a full-auto ultrasonic welding machine is its ability to enhance productivity. Traditional welding methods often require multiple steps, which can be time-consuming. However, with a full-auto machine, the phonon energy generated during the ultrasonic process means that parts can be bonded together in a matter of seconds. This speed not only increases throughput but also allows manufacturers to scale operations more effectively.

buy plcs-1a full-auto filter element ultrasonic welding machine

Moreover, these machines are designed to deliver superior weld strength and precision. The ultrasonic welder operates with millimeter-level accuracy, ensuring that each joint meets stringent quality standards. This is particularly important in industries where filter elements must adhere to strict regulatory requirements for functionality and safety, such as in automotive and medical applications.

Another aspect worth noting is the versatility of full-auto filter element ultrasonic welding machines. They can be tailored to accommodate various sizes and types of filter components, making them suitable for a wide range of applications. This adaptability allows companies to diversify their product offerings without significant capital investment in new equipment.

Additionally, investing in these state-of-the-art machines contributes to sustainability efforts. Ultrasonic welding is a clean process that eliminates the need for solvents or chemicals commonly found in traditional bonding methods. This leads to a reduction in hazardous waste, which is increasingly becoming a requirement in modern manufacturing practices.

In conclusion, the choice to invest in a full-auto filter element ultrasonic welding machine presents a multitude of advantages for manufacturers seeking to enhance their production processes. From improved efficiency and weld quality to greater versatility and environmental sustainability, these machines represent a significant leap forward in manufacturing technology. As industries continue to evolve and demand higher standards, adopting such advanced solutions is not just beneficial but essential for staying competitive in an ever-demanding market.

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025