کانوونی دووەم . 21, 2025 05:14 Back to list

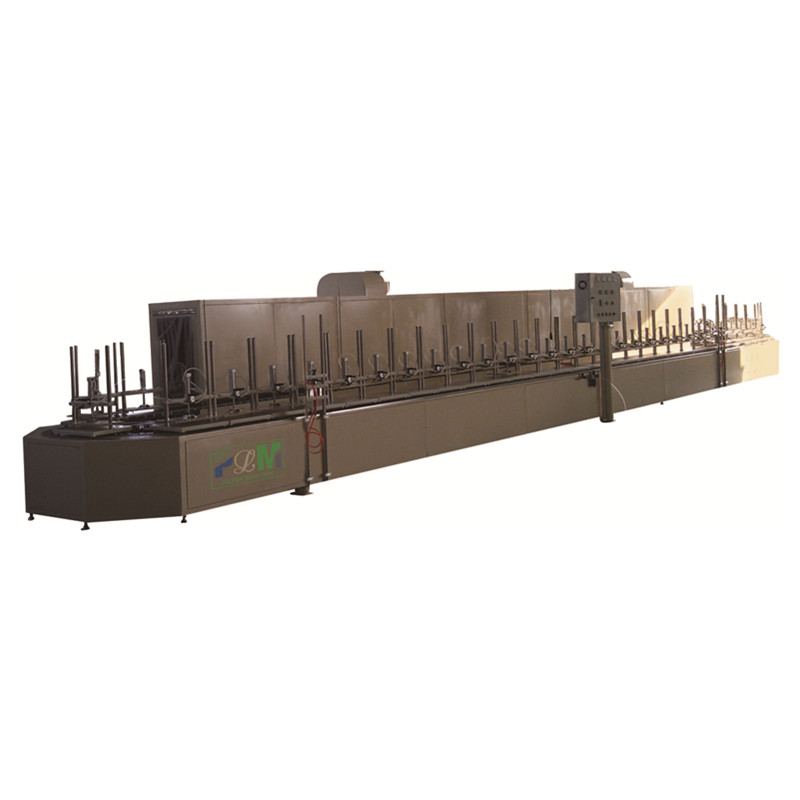

PLBL-60 Full-auto 60 stations U-type curing oven line

Oil filter paper, commonly overlooked as a mundane component, can significantly influence engine performance and longevity. Its primary function is to filter out impurities and contaminants from the engine oil, ensuring the engine operates efficiently. Understanding the nuances of oil filter paper not only aids in selecting the right product for specific needs but also enhances the knowledge in maintaining engine health, thereby reducing long-term operational costs.

In terms of real-world experience, users frequently report issues with engines stemming from neglected filter paper maintenance or incorrect specifications. It's recommended to adhere strictly to manufacturers' guidance on replacement intervals. Most experts suggest replacing oil filters during each oil change, usually between 3,000 to 5,000 miles, although some high-quality filters claim longer life spans. The expertise in manufacturing and selecting oil filter paper cannot be overstated. Trusted brands often undergo rigorous testing and quality assurance processes, ensuring their filter paper meets industry standards. Manufacturers utilize advanced technologies to craft filter papers capable of enduring extreme conditions, showcasing their authority and trustworthiness in the field. Tests from reputable laboratories provide measurable data on the performance of different oil filter papers, adding an extra layer of trustworthiness. Consumers are advised to consult independent test results when evaluating their options, ensuring they invest in reliable and efficient products. In summary, oil filter paper, though simple in concept, demands attention to detail and an understanding of underlying principles to maximize its effectiveness. By focusing on material quality, pore dynamics, structural integrity, and authoritative recommendations, vehicle owners can ensure optimal engine performance, protect their investment, and foster a deeper trust in their vehicle maintenance regimen.

In terms of real-world experience, users frequently report issues with engines stemming from neglected filter paper maintenance or incorrect specifications. It's recommended to adhere strictly to manufacturers' guidance on replacement intervals. Most experts suggest replacing oil filters during each oil change, usually between 3,000 to 5,000 miles, although some high-quality filters claim longer life spans. The expertise in manufacturing and selecting oil filter paper cannot be overstated. Trusted brands often undergo rigorous testing and quality assurance processes, ensuring their filter paper meets industry standards. Manufacturers utilize advanced technologies to craft filter papers capable of enduring extreme conditions, showcasing their authority and trustworthiness in the field. Tests from reputable laboratories provide measurable data on the performance of different oil filter papers, adding an extra layer of trustworthiness. Consumers are advised to consult independent test results when evaluating their options, ensuring they invest in reliable and efficient products. In summary, oil filter paper, though simple in concept, demands attention to detail and an understanding of underlying principles to maximize its effectiveness. By focusing on material quality, pore dynamics, structural integrity, and authoritative recommendations, vehicle owners can ensure optimal engine performance, protect their investment, and foster a deeper trust in their vehicle maintenance regimen.

Latest news

-

PLAB-6 A B Compound Filter Gluing Machine - Hebei Filter Man

NewsAug.13,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man|Precision Gluing&Industrial Automation

NewsAug.13,2025

-

PLAB-6 A/B Gluing Machine-Hebei Filter Man|Precision Gluing&Efficient Adhesive Application

NewsAug.13,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man|Precision Gluing, Industrial Filtration

NewsAug.13,2025

-

Premium Active Carbon Air Filter for Air Purifier - Odor & VOCs

NewsAug.13,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine - Hebei Filter Man

NewsAug.12,2025