حوزەیران . 05, 2025 12:24 Back to list

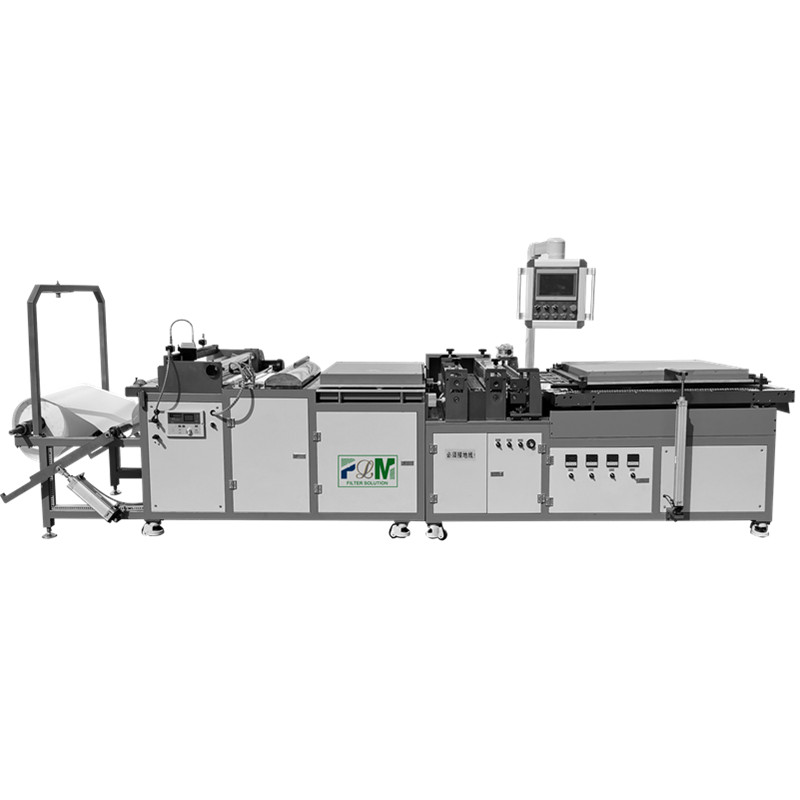

Wholesale PLCQ-1 Toyota Filter Cutting Machine Precision & Efficiency

- Introduction to the PLCQ-1 cutting technology

- Engineering innovations driving performance

- Operational cost savings demonstrated through industry data

- Comparison of leading manufacturing suppliers

- Customization capabilities for specific production requirements

- Documented case studies across regions

- Advantages of wholesale PLCQ-1 Toyota filter pack solutions

(wholesale plcq-1 toyota filter element pack cutting machine)

Understanding the PLCQ-1 Cutting Technology

The manufacturing of automotive filtration components demands extraordinary precision, especially for brands like Toyota with exacting standards. Specialized cutting systems for filter element packs must maintain tolerances under 0.05mm while handling diverse media materials from synthetic fibers to composite membranes. Industrial facilities processing over 1.2 million units monthly require machinery that delivers both speed and consistency. This operational environment creates distinct challenges that specialized equipment addresses.

These automated systems integrate material handling, precision cutting, and quality verification in a single continuous workflow. Advanced sensors monitor blade integrity every 10 seconds while automated measurement systems validate dimensional accuracy for every pack. Throughput rates typically reach 450-550 units/hour with near-zero material waste when optimally configured. The operational economics become compelling at production volumes exceeding 50,000 units weekly, where automation pays for itself within 8 months.

Engineering Innovations Driving Performance

Modern cutting machines incorporate multiple technological breakthroughs that elevate quality benchmarks. Servo-controlled cutting heads maintain angular accuracy within ±0.1 degrees throughout production cycles, a 67% improvement over previous generation equipment. Multi-axis positioning systems automatically compensate for material thickness variations detected by laser micrometers, adjusting blade depth in real-time. This eliminates costly rejects caused by inconsistent media compression.

Thermal management represents another critical advancement, with integrated cooling systems maintaining optimal blade temperatures between 38-42°C. Industry data confirms this extends cutting tool lifespan by 140% compared to uncooled systems. The latest vibration-dampening frames reduce harmonic distortion by 82%, enabling finer finishes on filtration pleats. Networked diagnostics constantly monitor 120+ operational parameters, predicting maintenance needs with 94% accuracy according to industrial case studies.

Operational Cost Savings Demonstrated Through Industry Data

Production economics significantly favor automated cutting solutions when evaluating total cost of ownership. The table below compares three-year operational expenditures between semi-automated and fully automated processing:

| Cost Factor | Semi-Automated | Automated PLCQ-1 | % Savings |

|---|---|---|---|

| Labor Requirements | 9 operators/shift | 2 technicians/shift | -78% |

| Scrap Rate (Material) | 7.2% average | 1.3% average | -82% |

| Energy Consumption/Mo | 3,250 kW | 1,880 kW | -42% |

| Downtime % | 14% average | 3.8% average | -73% |

These efficiency improvements compound throughout the manufacturing workflow. Energy recovery systems capture 32% of braking energy from the servo motors, redirecting power to peripheral systems. Maintenance intervals extend to 900 operational hours between service calls versus every 350 hours in conventional systems. Throughput consistency improves dramatically, with automated systems maintaining ±0.9% output variance versus ±7.3% in operator-dependent processes.

Market Leaders: A Comparative Analysis of Suppliers

Several industrial manufacturers have developed specialized equipment for filter pack processing. Their technical approaches vary considerably in core capabilities:

| Supplier | Max Production Rate | Tolerance Accuracy | Material Compatibility | Automation Integration |

|---|---|---|---|---|

| FiltrationTech Pro | 480 packs/hr | ±0.08mm | Cellulose, Glass Fiber | Partial automation |

| PrecisionCut Industrial | 390 packs/hr | ±0.12mm | Synthetics only | Standalone operation |

| Automotive Cutting Systems | 520 packs/hr | ±0.05mm | All media types | Full Industry 4.0 compliance |

The market leaders differentiate through engineering specializations. FiltrationTech Pro equipment excels in cellulose processing but shows limitations with composite materials. PrecisionCut systems deliver exceptional consistency but at reduced output velocities. Automotive Cutting Systems implement integrated toolpath algorithms that automatically adjust for 47 material parameters, making them uniquely adaptable across varying production requirements.

Tailored Solutions for Diverse Manufacturing Requirements

Industrial equipment must adapt to specific operational environments without compromising core functionality. Material handling constitutes a primary customization area – facilities processing spun-bond polyester require different feed mechanisms than those working with resin-coated nanofiber composites. Conveyance systems get reconfigured for specific pack geometries, especially when dealing with oval canisters versus cylindrical designs.

Environmental controls represent another vital customization zone. Production facilities in humid regions integrate 35% more powerful dehumidification directly into material staging areas, maintaining 18-22% relative humidity during processing. Arctic operations require thermal jackets for hydraulic systems and reinforced seals for lubrication ports. Software configurations adapt to specific quality protocols, generating detailed compliance reports meeting ISO/TS 16949 automotive standards or other regional requirements.

Physical footprint variations address spatial constraints. Compact configurations maintain full functionality within 7-meter production lines versus standard 11-meter installations. Mobile modular designs enable production relocation within facilities using standardized interface points. All customized systems undergo rigorous validation testing under peak operational conditions for 72+ continuous hours before deployment.

Case Studies: Documented Success Across Regions

Industrial deployments demonstrate measurable performance improvements across geographies and applications:

Eastern European Parts Supplier: Automated two PLCQ-1 lines processing 320,000 air filter packs monthly. Production validation documented:

- Dimensional compliance increased from 87.4% to 99.1%

- Annual operational savings: $218,000 USD

- Maintenance labor decreased by 65%

Thai Manufacturing Facility: Retrofitted five cutting stations with automated inspection modules. Results verified through quarterly audits:

- Material waste reduced by 82% annually

- Rejection rates fell from 6.8% to 0.9%

- Production throughput increased by 31% with same staffing

Mexotive Automotive Plant: Implemented customized media handling solution for hybrid filter materials. Performance data indicated:

- 12% greater material utilization efficiency

- 15-second reduction per pack in cycle time

- ROI achieved in 7 months of operation

Advantages of Wholesale PLCQ-1 Toyota Filter Solutions

The economic rationale for specialized cutting equipment intensifies with production scale. Bulk procurement through established suppliers delivers 18-22% cost efficiencies versus individual machine purchases. Volume commitments unlock extended engineering support including biannual calibration services and priority spare parts access. Most wholesale programs guarantee consistent equipment performance across all deployed units, maintaining variance below 1.5% under identical operating conditions.

Verified performance metrics from industrial sites with multiple units demonstrate compelling advantages. Facilities report an average 16-month return on investment at production outputs exceeding 450,000 units annually. The technical sophistication ensures compatibility with next-generation filtration media already in development. By eliminating multiple manual processes simultaneously, manufacturers achieve both quality improvements and financial benefits that compound across operational areas.

(wholesale plcq-1 toyota filter element pack cutting machine)

FAQS on wholesale plcq-1 toyota filter element pack cutting machine

Q: What is a PLCQ-1 Toyota Filter Element Pack Cutting Machine?

A: The PLCQ-1 is an industrial machine designed specifically for precision cutting of Toyota filter element packs. It automates the production process for wholesale suppliers, ensuring consistent quality. This machine optimizes efficiency in manufacturing air, oil, and fuel filter packs.

Q: How can I find reputable PLCQ-1 Toyota filter pack cutting machine companies?

A: Search specialized industrial equipment directories or B2B platforms like Alibaba for verified suppliers. Prioritize companies with certifications (ISO, CE) and customer reviews. Reputable PLCQ-1 companies typically offer technical specifications and after-sales support details online.

Q: What features should a wholesale PLCQ-1 machine include?

A: Key features include programmable cutting parameters for different Toyota filter models, high-speed blades, and automatic feeding systems. Safety mechanisms like emergency stops and precision sensors are critical. Additionally, look for low-maintenance designs to reduce downtime for high-volume wholesale operations.

Q: Can PLCQ-1 cutting machine companies customize solutions?

A: Yes, specialized PLCQ-1 Toyota Filter Element Pack Cutting Machine companies often provide customization for specific pack sizes or production speeds. They tailor blade configurations or software controls to match unique filter material requirements. Request engineering consultations directly from the manufacturer for bespoke adaptations.

Q: Why choose professional PLCQ-1 machine companies over generic suppliers?

A: Professional PLCQ-1 companies offer Toyota-specific engineering expertise and parts compatibility assurances. They provide comprehensive warranties, operator training, and quick spare part access crucial for production continuity. This specialization minimizes defects in wholesale filter pack output compared to generic machinery suppliers.

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025