Nov . 28, 2024 02:01 Back to list

Spin-On Oil Filter Manufacturing Line Solutions and Support Services

Optimizing Efficiency in Spin-On Oil Filter Production Line Services

In the automotive industry, the demand for reliable and efficient oil filtration systems is critical. Among the various oil filtration products available, spin-on oil filters have emerged as a popular choice due to their convenience and effectiveness. The production of these filters requires a sophisticated approach that blends technology, quality control, and efficient service management. This article delves into the intricacies of the spin-on oil filter production line and the services that can enhance its efficiency.

Understanding Spin-On Oil Filters

Spin-on oil filters are designed for easy installation and replacement. They typically consist of a sealed metal canister, a filter media, and a central post used for mounting. The design ensures a tight seal while also enabling quick swapping and disposal, making it an ideal choice for both vehicle maintenance technicians and DIY enthusiasts.

The spin-on oil filter market has experienced significant growth, fueled by an increase in vehicle production and a burgeoning automotive aftermarket. As a result, manufacturers are continually seeking ways to improve their production lines to cater to this growing demand without compromising quality.

The Spin-On Oil Filter Production Line

A production line for spin-on oil filters encompasses multiple stages, starting from raw material procurement and ending with the final quality check. The key steps include

1. Material Selection High-quality materials are paramount for producing durable filters. Manufacturers must choose the right metal for the canister and the appropriate filter media to ensure optimal filtration.

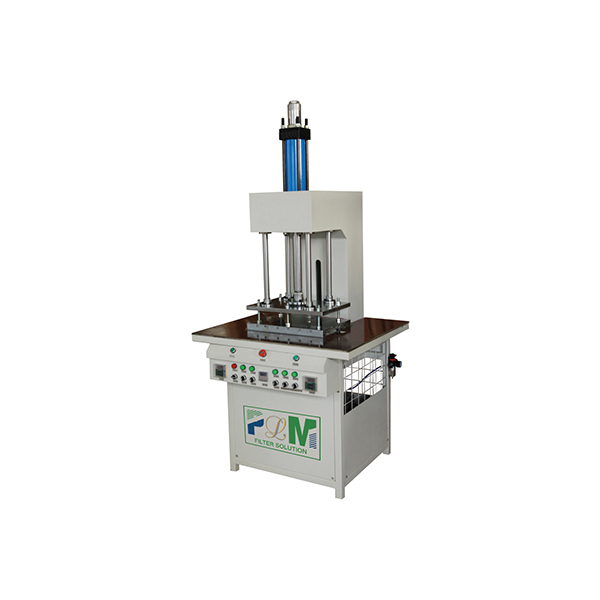

2. Manufacturing Process This phase involves stamping the canister, cutting the filter media, and assembling the components. Modern production lines utilize automated equipment to enhance precision and speed. Robotics and conveyor systems play a crucial role in minimizing errors and increasing throughput.

3. Quality Control Quality assurance is vital at every stage of the production process. Regular inspections are performed to ensure that each filter meets industry standards. This includes pressure testing and efficiency testing of the filter media to confirm that it effectively captures contaminants.

spin-on oil filter production line service

4. Packaging and Distribution Once filters complete quality checks, they are packaged for distribution. Efficient logistics ensure that products reach customers promptly, which expands market reach and enhances customer satisfaction.

Enhancing Production Line Services

To optimize the spin-on oil filter production line, manufacturers should focus on several critical service aspects

1. Preventive Maintenance Implementing a regular maintenance schedule for the machinery involved in production can prevent unexpected downtime. This proactive approach helps in identifying potential issues and extending the equipment's lifespan.

2. Training and Development Continual training of staff is crucial for maintaining high production standards. Workshops and training sessions can help workers stay updated on best practices, new technologies, and safety protocols.

3. Data Analytics and Process Optimization Embracing data-driven decision-making can unlock significant insights into production efficiency. By analyzing production data, manufacturers can pinpoint bottlenecks and streamline processes, leading to enhanced productivity.

4. Sustainable Practices As environmental concerns continue to grow, companies should consider implementing sustainable practices within their production lines. This could involve recycling materials, minimizing waste, and adopting energy-efficient technologies.

5. Customer Feedback Integration Actively seeking and integrating customer feedback can provide valuable insights into product performance. Understanding customer needs and preferences allows manufacturers to fine-tune their offerings and services, leading to better market alignment.

Conclusion

The production of spin-on oil filters is an intricate process that requires a sophisticated production line backed by effective services. By focusing on preventive maintenance, staff training, data analytics, sustainability, and customer feedback, manufacturers can significantly enhance their operational efficiency and meet the growing demands of the automotive industry. As the market evolves, continuous improvement in these areas will be essential for staying competitive and providing high-quality products that meet customer expectations.

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025