Dec . 04, 2024 18:04 Back to list

oil filter machine quotes

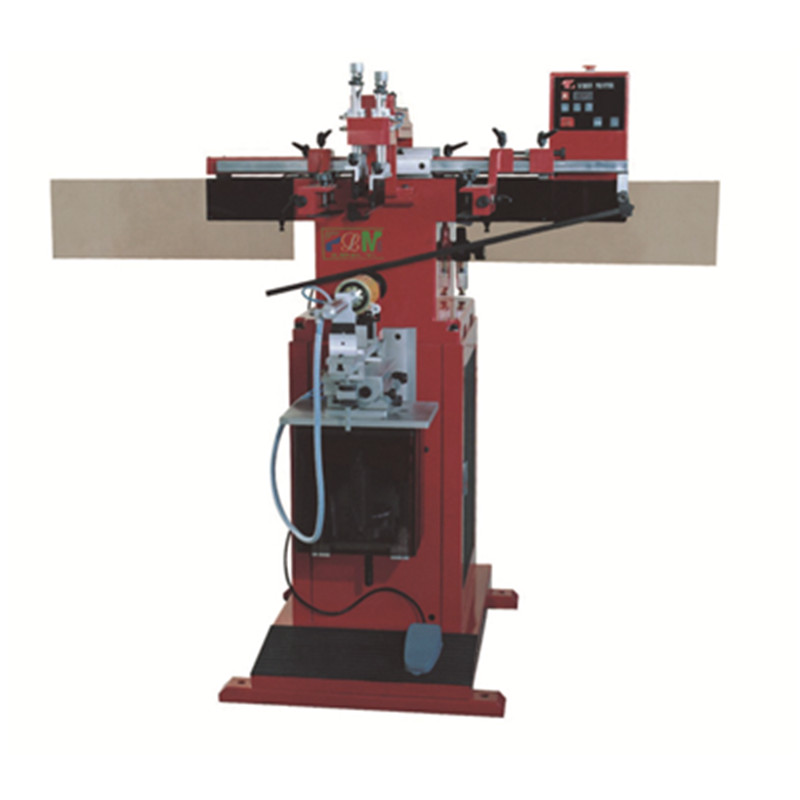

Understanding Oil Filter Machines A Comprehensive Analysis

In the world of manufacturing and industrial processes, the significance of maintaining quality and efficiency cannot be overstated. One essential component contributing to this objective is the oil filter machine. These machines play a crucial role in the treatment and recycling of oil, ensuring that it remains pure and effective for industrial applications. This article delves into the importance of oil filter machines, their operation, and factors to consider when seeking quotes for these machines.

The Importance of Oil Filter Machines

Oil filter machines are engineered to remove impurities, contaminants, and particulate matter from various types of oils, including lubricating oils, hydraulic oils, and cooking oils. The importance of these machines goes beyond mere cleanliness; they directly influence the longevity of machinery and equipment, optimally reducing friction, wear, and operational failures.

In industries such as automotive, manufacturing, and aviation, the quality of oil can determine the efficiency of an operation. Contaminated oil can lead to increased wear on engine parts, reduced machinery lifespan, and higher maintenance costs. Therefore, investing in a quality oil filter machine is not just a matter of compliance but a strategic decision to decrease overhead costs and improve productivity.

How Oil Filter Machines Operate

Typically, oil filter machines operate through a combination of physical and chemical processes. Most models incorporate a series of filtration mechanisms, such as mesh screens, sedimentation chambers, and activated carbon filters. The oil is passed through these various stages to ensure that all contaminants are removed effectively.

The filtration process usually begins with a pre-filtering system to capture larger particles. Following this, finer filtration methods are employed, utilizing different materials that attract and trap smaller impurities. The end result is cleaner oil that can be reused or repurposed, thereby promoting an eco-friendly approach by minimizing waste.

Factors to Consider When Requesting Quotes

oil filter machine quotes

When looking to purchase an oil filter machine, there are numerous factors to consider to ensure that you are making a wise investment. Here are several aspects to keep in mind

1. Machine Capacity Determine the volume of oil that needs filtration regularly. Different machines have different throughput capacities, and selecting one that suits your production scale is crucial.

2. Filtration Technology Some machines use standard filtering processes, while others may incorporate advanced technologies, such as centrifuges or membrane filtration. Analyze the specific filtration needs of your operations and choose accordingly.

3. Durability and Maintenance Investigate the materials used in the construction of the machine. Machines made from high-quality, corrosion-resistant materials may have longer lifespans. Additionally, inquire about maintenance requirements to assess the long-term operating costs.

4. Energy Efficiency Look for machines that meet modern energy efficiency standards. Energy-efficient machines may have a higher upfront cost but can lead to significant savings in operating expenses over time.

5. Warranty and Support Ensure that the manufacturer offers a comprehensive warranty and reliable customer support. This will provide peace of mind and assistance in case of any operational issues.

6. Cost Finally, gather quotes from multiple suppliers. Be wary of prices that seem too low, as they may reflect inferior quality. Instead, consider the balance between price and the features offered.

Conclusion

Oil filter machines are undoubtedly a cornerstone of industrial operations that depend on oil. By enhancing oil purity and extending the life of equipment, these machines contribute to increased efficiency and reduced operational costs. As industries continue to prioritize sustainability and performance, the demand for reliable oil filter machines is expected to grow. By understanding what to look for and considering crucial factors when requesting quotes, businesses can make informed decisions that pave the way for improved productivity and sustainability in their operations.

-

Premium HEPA Air Filter for Dyson Parts | Efficient Filtration

NewsAug.04,2025

-

AI-Optimized Active Carbon Filter for Air Purifiers | 51 chars

NewsAug.02,2025

-

Premium Active Carbon Air Filter for Air Purifiers | Odor Removal

NewsAug.01,2025

-

Activated Carbon Air Filters: Ultimate Odor Removal for Purifiers

NewsJul.31,2025

-

PP Spun Filter Cartridge Making Machine for Efficient Filtration Solutions

NewsJul.29,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor & Pollutant Removal

NewsJul.29,2025