Окт . 07, 2024 04:33 Back to list

cylindrical filter products

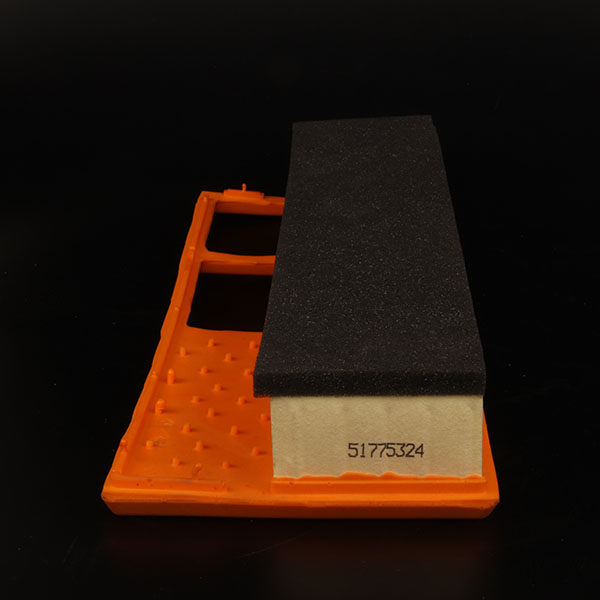

Understanding Cylindrical Filter Products A Comprehensive Overview

Cylindrical filter products are essential components in various industries, primarily due to their effective filtration capabilities. These filters are designed in a cylindrical shape, which provides a large surface area, enhancing their efficiency in separating solids from liquids and gases. This article will delve into the characteristics, applications, and advantages of cylindrical filter products.

Characteristics of Cylindrical Filters

Cylindrical filters are typically made from different materials depending on their intended use. Common materials include stainless steel, plastic, and composite materials, each offering unique benefits such as corrosion resistance, durability, and flexibility. The cylindrical shape allows for increased flow rates while maintaining a reduced footprint, which is particularly beneficial in space-constrained environments.

The structure of these filters is crucial in determining their performance. Most cylindrical filters feature a porous membrane or media that captures particles while allowing fluids to pass. The pore size of the filtration media can be tailored to target specific contaminants, making cylindrical filters versatile across various applications.

Applications Across Industries

Cylindrical filter products find applications in multiple sectors, including automotive, aerospace, pharmaceuticals, water treatment, and food and beverage. In the automotive industry, for instance, they are commonly used in fuel filtration systems, ensuring that impurities do not enter the engine. In the aerospace sector, these filters play a critical role in ensuring the cleanliness of fuel and hydraulic systems.

cylindrical filter products

In the realm of pharmaceuticals, cylindrical filters are integral in the manufacturing process, where they help maintain product purity by removing particulates. Water treatment facilities employ cylindrical filters to ensure that drinking water is free from harmful contaminants, contributing to public health and safety. Moreover, in the food and beverage industry, these filters help maintain quality and safety standards, protecting consumers from potentially harmful substances.

Advantages of Cylindrical Filters

One of the primary advantages of cylindrical filter products is their efficiency. The cylindrical form promotes uniform flow and minimizes pressure drop, allowing for increased throughput and longer service life. This efficiency translates to lower operational costs over time, making them an economically viable option for many businesses.

Additionally, cylindrical filters are often easy to maintain and replace, which further contributes to their overall cost-effectiveness. Many designs incorporate features that allow for quick cleaning or cartridge replacement, reducing downtime and ensuring continuous operation.

Another significant advantage is their adaptability. With variations in media type, pore size, and construction materials, cylindrical filters can be tailored to meet specific filtration requirements. This customization ensures optimal performance in diverse applications, from coarse filtration to fine purification.

Conclusion

Cylindrical filter products are integral components in numerous industries, providing reliable filtration solutions that enhance efficiency and maintain product integrity. Their unique characteristics, wide range of applications, and numerous advantages position them as a vital investment for any business prioritizing quality and performance. As technologies advance and industries evolve, the role of cylindrical filter products will undoubtedly become even more significant in ensuring clean and safe processes across the board.

-

Premium Engine Oil Filter Supplier & Exporter Reliable Engine Oil Filter Service

NewsJul.04,2025

-

Wholesale PLRZ-1000N Full-Auto Hot Melt Filter Paper Bonding Machine - High Efficiency & Precision

NewsJul.04,2025

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025