Дек . 10, 2024 06:32 Back to list

Element Filter Exporter for Enhanced Data Processing and Analysis

Understanding Filter Element Exporters A Comprehensive Overview

In the realm of industrial processes and environmental management, the concept of filter element exporters is increasingly gaining prominence. This topic encompasses a range of disciplines, including engineering, manufacturing, and sustainability, and serves as a critical component in maintaining efficient operations in various industries. In this article, we will delve into what filter element exporters are, their significance, applications, and the future trends in this field.

What are Filter Element Exporters?

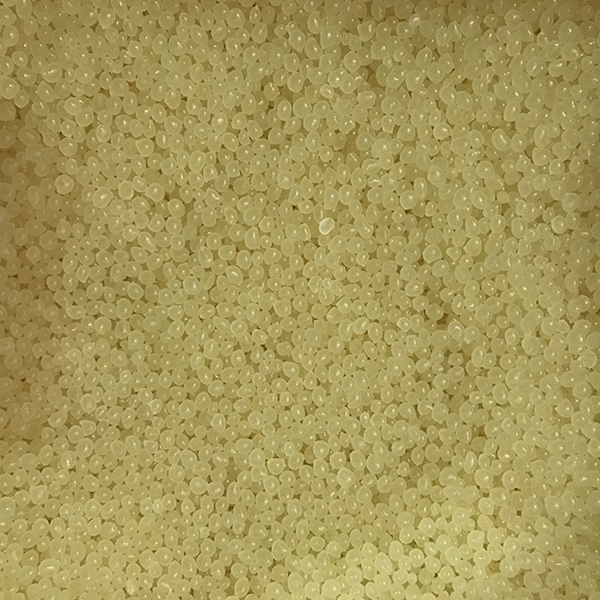

At its core, a filter element exporter is an entity involved in the production and supply of filter elements, which are critical components designed to remove impurities and contaminants from gases, liquids, or even semi-solids. These exporters play a vital role in ensuring that filtration systems operate at peak efficiency. Filter elements come in various forms, including but not limited to cartridges, membranes, and bags, each designed for specific applications and types of contaminants.

The Importance of Filter Elements

The role of filter elements cannot be overstated. In industrial settings, the filtration process is essential for maintaining equipment efficiency, reducing operational costs, and ensuring product quality. By removing unwanted particles, filter elements help protect machinery and extend its life, resulting in fewer breakdowns and repairs. Additionally, in sectors such as pharmaceuticals and food processing, filter elements are crucial for ensuring the safety and purity of products, thus meeting stringent regulatory requirements.

Applications Across Industries

Filter element exporters serve a multitude of industries, reflecting the diverse applications of filtration technology. In the automotive industry, for instance, air filter elements are crucial for ensuring clean air intake, enhancing engine performance, and minimizing emissions. In the oil and gas sector, filter elements are integral to separating water and particulates from fuels, thereby preventing operational disruptions.

The water treatment industry also heavily relies on filter element exporters. The need for clean and safe drinking water has led to the development of advanced filtration technologies, including reverse osmosis membranes and activated carbon filters. These elements are critical for removing contaminants and ensuring the water meets health standards.

filter element exporter

Moreover, in the realm of environmental protection, filter elements play an essential role in air purification systems. With increasing concerns over air quality and pollution, industries are implementing superior filtration methods to meet regulatory standards and contribute to environmental sustainability.

Challenges Faced by Filter Element Exporters

Despite the growing demand for filter elements, exporters face several challenges. One significant issue is the need for constant innovation to keep pace with advancing technologies and changing industrial needs. Filter element exporters must invest in research and development to create more efficient, durable, and eco-friendly products.

Additionally, competition in the market is becoming fierce, with numerous players vying for market share. Exporters must differentiate themselves through quality, customer service, and technological advancements to maintain a competitive edge. Supply chain disruptions, particularly in the wake of global events such as the COVID-19 pandemic, have also posed risks to manufacturers and exporters, affecting their ability to meet customer demands.

Future Trends

Looking ahead, several trends are likely to shape the future of filter element exporters. One significant trend is the increasing emphasis on sustainability. There is a growing demand for biodegradable and recyclable filter elements as industries strive to reduce their environmental footprints. Exporters who can innovate in this area will likely see increased opportunities.

Moreover, the integration of smart technology into filtration systems is on the rise. Sensors and IoT (Internet of Things) devices can monitor filter performance in real-time, enabling predictive maintenance and reducing downtime. Filter element exporters that embrace these digital advancements will be well-positioned to meet the evolving needs of their clients.

Conclusion

Filter element exporters play a crucial role in a wide array of industries by supplying essential components that enhance efficiency, ensure compliance with regulations, and promote sustainability. As industries continue to evolve and face new challenges, the importance of these exporters will only grow. Their ability to innovate and respond to market demands will be critical in shaping the future of filtration technology and its applications across the globe. In a world increasingly focused on environmental stewardship and operational efficiency, the filter element exporter stands as a vital link in the chain of responsible industrial practice.

-

Premium Coffee Filter Rolling Paper: Fine Mesh for Smooth DIY

NewsAug.27,2025

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025