ഡിസം . 25, 2024 11:07 Back to list

Discounted Production Line for Cabin Air Filter Manufacturing Solutions

Optimizing Production Discounting Strategies for Cabin Air Filters

The modern automotive industry has seen significant advancements in technology and manufacturing processes, leading to increased efficiency and innovation in the production of various components. One essential part that has gained attention over the years is the cabin air filter, which plays a crucial role in ensuring the quality of air circulated within vehicles. Yet, as the competition grows and consumer demands shift towards more cost-effective solutions, manufacturers must explore discounting strategies within their production lines for cabin air filters. This article delves into the importance of discounting practices and how they can be strategically implemented in the production of cabin air filters.

Cabin air filters serve a vital function in vehicles, trapping dust, pollen, and other airborne particles before they enter the cabin. Consequently, they contribute significantly to passenger comfort and health. With the rise in environmental awareness and hygiene consciousness, the demand for high-quality cabin air filters has surged. However, this demand must be balanced with competitive pricing to stay relevant in the market. Manufacturers are thus under increasing pressure to develop cost-efficient production lines.

Implementing discount strategies can be a game changer for manufacturers. These discounting practices can target various aspects of production, such as materials, processing, and distribution. For instance, sourcing raw materials in bulk can lead to substantial reductions in costs. Establishing long-term relationships with suppliers might also open the door to exclusive deals and discounts that can be leveraged against fluctuating market prices.

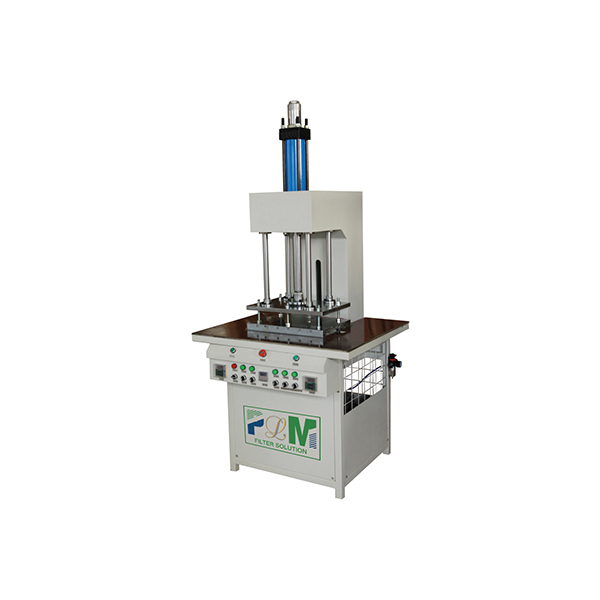

Automation in manufacturing processes represents another avenue to achieve discounts. By investing in advanced machinery and robotic systems, manufacturers can enhance operational efficiency and reduce labor costs. Automation not only speeds up production but also ensures consistent product quality, minimizing waste and rework, which are often costly in any production line. With improved efficiency, manufacturers can afford to pass on some of the savings to consumers through competitive pricing.

discount cabin air filter production line

Moreover, adopting lean manufacturing principles can significantly impact the cost structure in production lines. By streamlining operations, reducing waste, and optimizing resource utilization, manufacturers can lower their overhead costs. The philosophy of 'lean' encourages continuous improvement and focuses on delivering value to the customer while eliminating waste, which aligns perfectly with discounting strategies.

Effective inventory management also plays a critical role in achieving cost reductions. Just-in-time (JIT) inventory systems can help manufacturers minimize holding costs. By producing cabin air filters based on actual demand rather than forecasts, manufacturers can reduce excess inventory and avoid discounting unsold products, thus maintaining a healthier profit margin.

In addition, marketing strategies that emphasize the benefits of high-quality cabin air filters can create a perception of value, allowing manufacturers to justify limited discounts effectively. Educating consumers on the advantages of using their specific products—such as improved air quality and enhanced vehicle performance—can cushion their prices, making any discount more impactful.

Furthermore, partnerships with automotive dealerships and service centers can amplify the effects of discounting strategies. Offering exclusive promotions to these partners not only drives sales but also increases brand visibility and loyalty. When customers perceive added value through discounts and promotional offers, they are more likely to associate the brand with affordability and quality.

In conclusion, the production of cabin air filters in today's automotive landscape requires a strategic approach to discounting. By optimizing production lines through cost-effective sourcing, automation, lean manufacturing, and savvy inventory management, manufacturers can maintain profitability while delivering high-quality products at competitive prices. As the automotive market continues to evolve, embracing these discounting strategies will be essential for manufacturers aiming to thrive and meet the growing expectations of consumers. In this ever-competitive industry, turning challenges into opportunities can set exceptional manufacturers apart from their rivals.

-

OEM Truck Air Filters Machine Production Line - Custom Solutions

NewsMay.18,2025

-

Toyota Air Filter Producing Machine High-Efficiency Manufacturing Solutions

NewsMay.18,2025

-

Affordable Truck Air Filters High Quality & Low Cost

NewsMay.18,2025

-

Spiral Filter Core Making Machine High-Precision & Automated Solutions

NewsMay.17,2025

-

Buy PL-CQ1 Toyota Filter Cutting Machine Precision & Efficient Design

NewsMay.17,2025

-

Wholesale PLCY-200 Fuel Filter Tester Precision Testing & Bulk Deals

NewsMay.16,2025