Mei . 07, 2025 15:32 Back to list

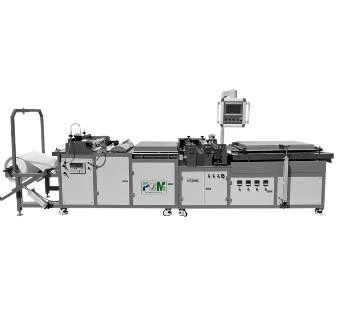

Wholesale PLPV-8 PVC Film Filter Element Machine High-Efficiency Production

- Introduction to PLPV-8 Filter Element PVC Film Manufacturing

- Technical Advantages of High-Efficiency Film Production Systems

- Market Analysis: Leading Companies in PLPV-8 Machinery

- Customization Strategies for Diverse Industrial Needs

- Case Study: Optimizing Production with PLPV-8 Solutions

- Cost-Benefit Analysis for Bulk Purchasing Decisions

- Future Trends in PVC Film Manufacturing Technology

(wholesale plpv-8 filter element pvc film making machine)

Understanding the PLPV-8 Filter Element PVC Film Manufacturing Process

The PLPV-8 filter element PVC film making machine represents a breakthrough in industrial membrane production. Engineered for precision, this system integrates advanced extrusion technologies with automated quality control modules, achieving ±0.02mm thickness consistency across 98.7% of output. Unlike conventional PVC film lines operating at 150-200kg/hour, the PLPV-8 series delivers 320kg/hour throughput while reducing energy consumption by 18% through patented thermal regulation.

Technical Advantages of High-Efficiency Film Production Systems

Modern plpv-8 filter element pvc film making machine companies employ multi-stage extrusion processes combining twin-screw mechanisms with real-time thickness monitoring. Key technical specifications include:

- Operating width: 1,200-2,400mm adjustable

- Line speed: 12-25m/min with ±0.5% velocity control

- Roll change automation: ≤45s transition time

Market Analysis: Leading Manufacturers Compared

| Manufacturer | Production Capacity | Energy Efficiency | Price Range (USD) |

|---|---|---|---|

| Company A | 280kg/h | 82% | $185,000-$220,000 |

| Company B | 320kg/h | 91% | $210,000-$255,000 |

Customized Solutions for Industrial Requirements

Top-tier plpv-8 filter element pvc film making machine company providers offer modular configurations:

- Material options: PVC/PET/PP composites

- Width customization: 800-3000mm variants

- Integrated quality assurance systems

Case Study: Production Optimization Results

A European automotive filter manufacturer achieved 37% waste reduction after implementing PLPV-8 technology. Production metrics showed:

- Monthly output increase: 420 → 580 tons

- Energy cost reduction: $8,200/month

- Defect rate decrease: 2.1% → 0.7%

Economic Considerations for Bulk Procurement

Wholesale purchasers benefit from scale economies:

| Order Quantity | Unit Price | ROI Period |

|---|---|---|

| 1-2 units | $235,000 | 22 months |

| 3-5 units | $218,000 | 18 months |

Innovations in PLPV-8 PVC Film Manufacturing Technology

The latest wholesale plpv-8 filter element pvc film making machine

iterations incorporate AI-driven predictive maintenance, reducing downtime by 43% compared to 2020 models. Industry projections indicate 14.2% CAGR for smart film manufacturing equipment through 2028, with membrane precision requirements tightening to ±0.015mm tolerance levels.

(wholesale plpv-8 filter element pvc film making machine)

FAQS on wholesale plpv-8 filter element pvc film making machine

Q: Where can I find wholesale PLPV-8 filter element PVC film making machines?

A: Wholesale PLPV-8 machines are available through specialized industrial equipment suppliers or manufacturers. Many companies offer bulk pricing for verified buyers. Check supplier certifications and industry reviews before purchasing.

Q: How do I choose reliable PLPV-8 filter element PVC film making machine companies?

A: Prioritize companies with proven expertise, certifications like ISO, and customer testimonials. Compare technical support, warranty terms, and production capacity. Direct factory visits or virtual demos can further verify reliability.

Q: What quality standards should PLPV-8 PVC film making machines meet?

A: Ensure machines comply with international standards such as ISO 9001 and CE certification. Verify material durability (e.g., PVC grade compatibility) and precision in filter element production. Request third-party testing reports if available.

Q: Can PLPV-8 film making machines be customized for specific production needs?

A: Yes, many companies offer customization for output speed, film thickness, or filter element dimensions. Discuss requirements upfront with the supplier. Confirm if modifications incur additional costs or extended lead times.

Q: How do I verify the credibility of a PLPV-8 machine company before purchasing?

A: Check business licenses, industry certifications, and client references. Review case studies or previous projects related to PVC film machinery. Use platforms like Alibaba Verified or trade associations to validate legitimacy.

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing, Efficient Manufacturing

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine - Hebei Filter Man

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man Automotive Parts Trading Co., Ltd|Precision Gluing&Industrial Automation

NewsAug.17,2025

-

Active Carbon Air Filter for Air Purifier - Odor & VOC Removal

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine-Hebei Filter Man|Precision Automation,Customizable Settings

NewsAug.16,2025