Dec . 06, 2024 16:52 Back to list

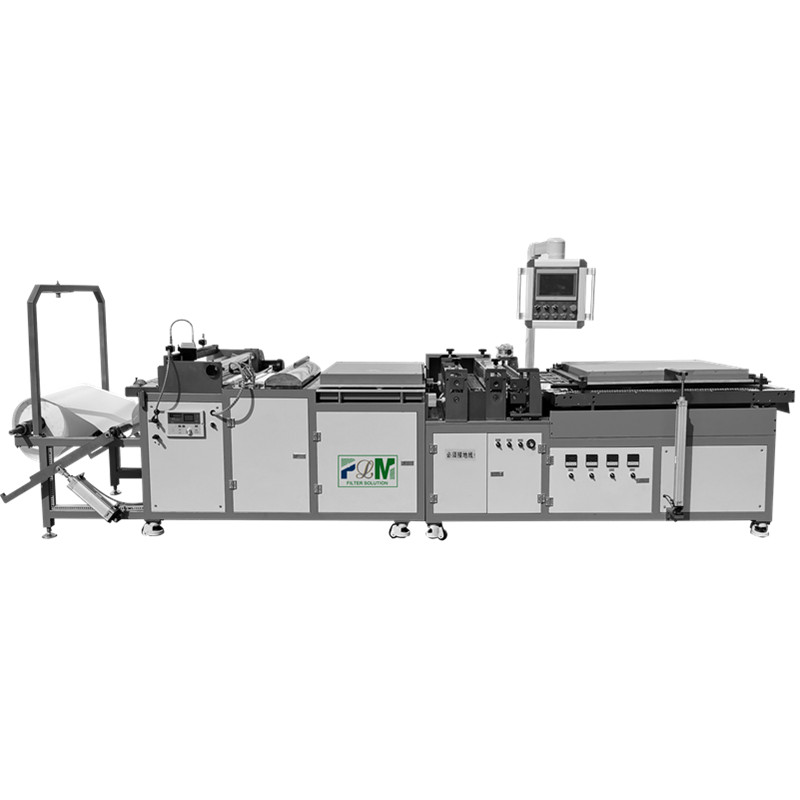

plks-1500 full-auto pp air filter plastic injection molding machine products

The Advancement of Plastic Injection Molding in Air Filter Production

In today's rapidly evolving industrial landscape, precision and efficiency are paramount. One of the remarkable advancements in manufacturing technology is the development of the PLKS-1500 full-auto PP air filter plastic injection molding machine. This innovative machinery is revolutionizing the production of air filters, significantly enhancing productivity and ensuring high-quality outputs.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process used for producing parts by injecting molten material into a mold. The process begins with melting down plastic pellets, which are then injected under high pressure into a mold cavity where they cool and solidify into the desired shape. This method is well-suited for mass production, providing consistent quality and the ability to create complex geometries that are often unachievable with other manufacturing techniques.

The Importance of Air Filters

Air filters play a crucial role in various applications, including automotive, industrial, and home appliances. They are vital for maintaining air quality, ensuring the efficiency of engines, and protecting sensitive equipment from pollutants. Given the increasing emphasis on air quality and environmental regulations, the demand for high-performance air filters is on the rise.

Features of the PLKS-1500 Machine

The PLKS-1500 full-auto PP air filter plastic injection molding machine is specifically designed for the efficient production of polypropylene (PP) air filters. Several key features set the PLKS-1500 apart from conventional machines

1. Fully Automated Operation The PLKS-1500 is engineered for complete automation, which minimizes human intervention and reduces the likelihood of errors. This feature streamlines the manufacturing process, leading to increased efficiency and decreased cycle times.

2. Energy Efficiency This machine incorporates state-of-the-art energy-saving technologies that significantly reduce power consumption. This not only reduces operational costs but also aligns with global sustainability goals.

3. Precision Control The PLKS-1500 boasts advanced control systems that allow for precise adjustments during the molding process. This capability ensures that the final products meet stringent quality standards, which is crucial for air filter applications.

plks-1500 full-auto pp air filter plastic injection molding machine products

4. Versatile Molding Capabilities The PLKS-1500 can handle a variety of PP grades, enabling manufacturers to produce a range of air filter designs to meet specific customer requirements. This flexibility is essential in a market where customization is increasingly demanded.

5. Rapid Production Cycle With its high clamping force and swift injection speed, the PLKS-1500 facilitates rapid cycle times, thereby increasing overall production capacity. This characteristic is especially beneficial for companies looking to meet high-volume orders efficiently.

Benefits for Manufacturers

The adoption of the PLKS-1500 machine brings numerous benefits to manufacturers of air filters

- Cost-Effectiveness By reducing cycle times and minimizing energy consumption, the PLKS-1500 leads to lower production costs while maintaining high-quality outputs.

- Consistency in Quality Automated systems ensure that each product meets the same quality standards, thus reducing waste and enhancing customer satisfaction.

- Enhanced Innovation The capability to produce complex designs encourages manufacturers to innovate and explore new markets for their air filter products.

- Scalability As demand for air filters continues to grow, the PLKS-1500 allows manufacturers to scale their operations efficiently to meet market demands without sacrificing quality.

Conclusion

The PLKS-1500 full-auto PP air filter plastic injection molding machine exemplifies the intersection of innovation and practicality in modern manufacturing. By enhancing efficiency, reducing costs, and ensuring high-quality outputs, this machine is setting a new standard in the production of air filters. As industries continue to prioritize air quality and environmental sustainability, the role of advanced machinery like the PLKS-1500 becomes increasingly vital. In a world where efficiency and quality are king, investing in such technology will undoubtedly provide a competitive edge in the air filter manufacturing sector.

-

Premium Coffee Filter Rolling Paper: Fine Mesh for Smooth DIY

NewsAug.27,2025

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025