Dec . 17, 2024 10:11 Back to list

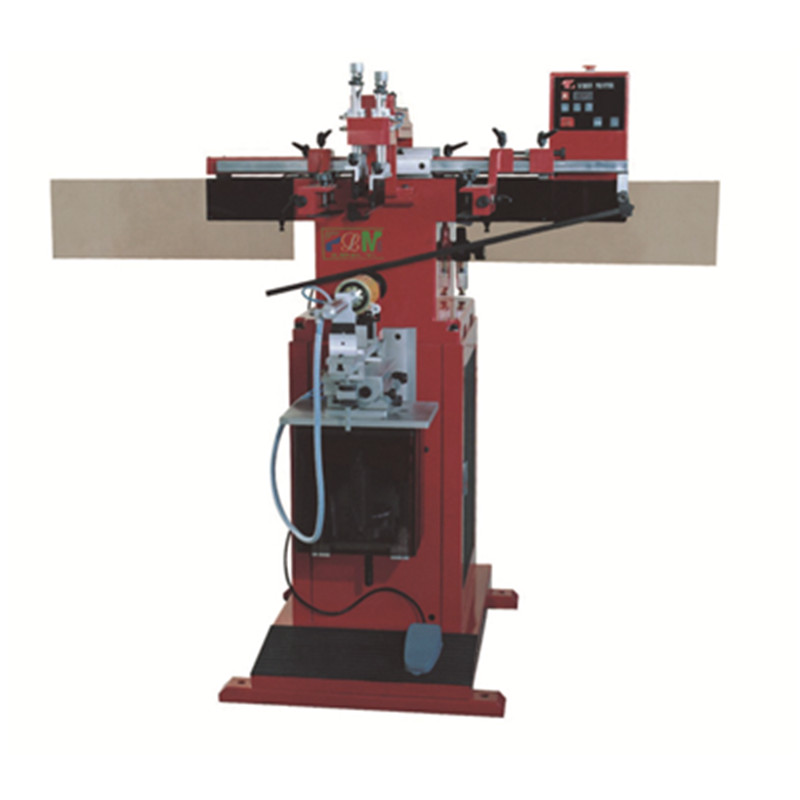

cheap plln-1 full-auto pp feeding machine

The Advantages of a Cheap Full-Auto PP Feeding Machine for Your Production Line

In today's fast-paced manufacturing environment, efficiency and cost-effectiveness are key to maintaining a competitive edge. One of the most crucial aspects of the production process is the feeding system. With the increasing demand for automation, full-auto PP (polypropylene) feeding machines have become a popular choice for businesses looking to optimize their operations. Among the various models available, affordable or cheap full-auto PP feeding machines offer an attractive solution for businesses of all sizes.

Understanding PP Feeding Machines

PP feeding machines are designed to automate the process of feeding polypropylene materials into production lines. These machines are typically used in industries such as packaging, textiles, and manufacturing, where precise feeding of materials is vital. The full-auto feature means that these machines can operate without constant human oversight, reducing labor costs and minimizing the potential for human error.

Cost-Effectiveness and Affordability

One of the most appealing aspects of cheap full-auto PP feeding machines is their affordability. Businesses can acquire these machines without significant financial strain, making them an excellent option for small and medium enterprises. The initial savings can be reinvested into other areas of the business, promoting growth and innovation.

Moreover, an affordable machine does not necessarily mean sacrificing quality. Many manufacturers are now producing reliable, efficient machines at lower price points due to advancements in technology and competition in the market. This allows businesses to enjoy the benefits of automation without breaking the bank.

Enhancing Efficiency and Productivity

A cheap full-auto PP feeding machine drastically enhances efficiency within a production line. By automating the feeding process, companies can significantly increase their output. These machines can operate continuously, ensuring that production runs smoothly without interruptions caused by manual feeding methods. This constant operation not only boosts productivity but also allows businesses to meet higher demand levels.

Additionally, the accuracy of feeding provided by these machines reduces waste significantly. In many manual processes, discrepancies in feeding can lead to overuse of materials or ineffective production. An automated system ensures that the materials are fed precisely as required, optimizing resource use and reducing overall costs.

Minimizing Labor Costs

cheap plln-1 full-auto pp feeding machine

Labor costs are a significant expense in manufacturing industries. By incorporating a cheap full-auto PP feeding machine, businesses can reduce their reliance on manual labor for material feeding tasks. This allows staff to focus on more critical aspects of the production process, such as quality control and machine maintenance.

Furthermore, automation increases the workplace's safety by reducing the need for workers to engage with machinery during the feeding process. Fewer manual interactions mean a lower likelihood of accidents, creating a safer work environment.

Easy Integration with Existing Systems

Another significant advantage of cheap full-auto PP feeding machines is their compatibility with existing production lines. Many manufacturers design these machines to be easily integrated into various systems. This adaptability means that businesses can upgrade their feeding systems without the need for extensive changes to their production infrastructure, keeping disruption to a minimum.

Maintenance and Reliability

When considering any piece of machinery, maintenance is a crucial factor. Cheap full-auto PP feeding machines are often designed with user-friendly features that simplify maintenance tasks. Many models come with self-diagnostic systems that alert operators to potential issues before they become serious, allowing for proactive maintenance.

Furthermore, the reliability of modern feeding machines means that the likelihood of breakdowns is significantly reduced. This reliability translates to less downtime, which is essential for maintaining productivity in a competitive manufacturing environment.

Conclusion

In conclusion, the introduction of a cheap full-auto PP feeding machine can transform the operational efficiency of businesses within various industries. With their affordability, efficiency, reduced labor costs, compatibility with existing systems, and ease of maintenance, these machines present an attractive opportunity for companies looking to enhance their production processes.

Investing in such technology not only offers immediate financial benefits but also positions businesses for long-term success in a rapidly evolving marketplace. As the demand for automation continues to grow, integrating an automated feeding machine into your production line may well be a strategic move toward achieving greater efficiency and profitability.

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025